IoT and Edge Computing: Unlocking Trillion-Dollar Value in the Energy Sector

August 28, 2025 / Bryan Reynolds

The Trillion-Dollar Shift: How IoT and Edge Computing Are Redefining Profitability and Resilience in the Energy Sector

Introduction: The High Cost of the Status Quo

In the high-stakes world of energy, operational downtime is not just an inconvenience; it is a catastrophic financial event. For a large oil and gas operator, a single day of unplanned downtime can cost more than $20 million, and such incidents occur, on average, five times a year. This reality underscores a fundamental vulnerability in the sector's traditional operational model: a reactive approach to maintenance and management that costs the industry billions annually in lost revenue, emergency repairs, and reputational damage. The status quo, built on periodic manual inspections and scheduled maintenance, is no longer tenable in an era of volatile markets, aging infrastructure, and escalating consumer demand.

A fundamental strategic shift is underway, moving the industry from this reactive posture to a proactive, data-driven paradigm. At the heart of this transformation are two interconnected technologies: the Internet of Things (IoT) and Edge Computing. These are not merely incremental upgrades but the foundational pillars of a new operational philosophy. IoT provides real-time visibility into the health and performance of every critical asset, while Edge Computing delivers the localized intelligence to act on that information in milliseconds. Together, they represent the central nervous system and reflexes of the modern energy enterprise.

This report serves as a definitive guide for B2B executives navigating this complex transition. Adopting the ‘They Ask You Answer’ approach, it will address the most pressing questions facing industry leaders today: What are these technologies, and why are they commanding billions in investment? What is the proven financial return on these initiatives? What are the most significant risks and implementation hurdles? And most critically, how can an organization architect a solution that not only solves today's problems but also provides a scalable foundation for future innovation?

1. What Are IoT and Edge Computing, and Why Is the Energy Sector Investing Billions?

To grasp the strategic importance of this technological wave, it is essential to first understand the distinct but synergistic roles of IoT and Edge Computing. They are the core components enabling the digital transformation of physical industrial assets.

Core Concepts for the Executive

The Internet of Things (IoT): The Digital Nervous System At its core, the Internet of Things in the energy sector is the vast network of sensors, smart meters, and connected devices embedded within physical infrastructure. Think of it as the digital nervous system for every pump, turbine, transformer, and pipeline. These devices continuously collect and transmit granular, real-time data on a wide range of operational parameters—vibration, temperature, pressure, flow rate, energy consumption, and more. This capability represents a monumental leap from the past, replacing sporadic, labor-intensive manual checks with a constant, automated stream of high-fidelity operational intelligence. The primary function of IoT is to provide unprecedented visibility, transforming opaque physical processes into transparent, measurable, and optimizable digital workflows.

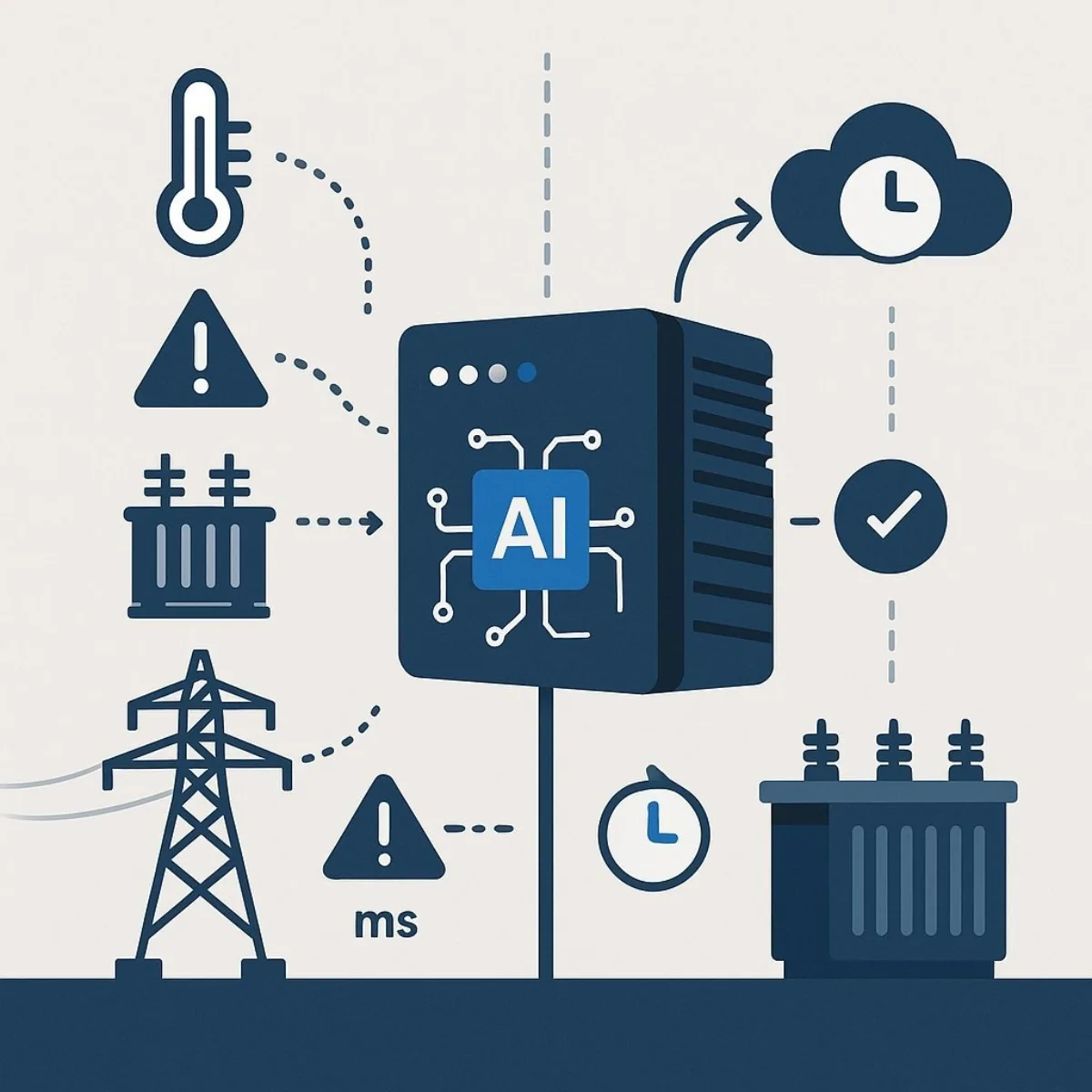

Edge Computing: The Instantaneous Reflex If IoT is the nervous system that senses a problem, Edge Computing is the reflex that prevents the injury. Edge Computing is a decentralized computing paradigm where data processing occurs at or near the source of data generation —on or close to the IoT device itself—rather than being transmitted to a centralized cloud or data center for analysis. This architectural choice is critical for applications where latency—the delay in data transmission and processing—is unacceptable. For a power grid on the verge of instability or a critical pump showing early signs of catastrophic failure, waiting seconds for a response from a distant cloud server is not an option. Edge computing enables localized, real-time decision-making, allowing systems to analyze data and trigger an automated response in milliseconds, fundamentally changing the speed at which an organization can react to operational events.

The Market Imperative

The energy sector's commitment to this transformation is not speculative; it is a multi-billion-dollar reality reflected in aggressive market growth projections. The global IoT in energy market, valued at approximately USD 22.02 billion in 2022, is projected to more than double to USD 52.17 billion by 2030, driven by a compound annual growth rate (CAGR) of 11.39%. Other, more aggressive market analyses forecast an even steeper trajectory, with the market potentially surging from USD 84.84 billion in 2024 to USD 710.64 billion by 2034, reflecting a blistering CAGR of 23.68%. This massive capital allocation is not driven by technological novelty but by the urgent strategic need to modernize aging grid infrastructure, improve operational efficiency, and meet the rising demands of consumers and regulators.

| Market Forecast Source | 2022/2024 Value (USD Billion) | 2030/2034 Value (USD Billion) | Forecast CAGR |

|---|---|---|---|

| Zion Market Research | $22.02 (2022) | $52.17 (2030) | 11.39% |

| Market Research Future | $84.84 (2024) | $710.64 (2034) | 23.68% |

| Fortune Business Insights | $61.02 (2022) | $222.56 (2030) | 17.8% |

Table 1: The Exponential Growth of IoT in the Global Energy Market. Multiple market analyses project robust, double-digit growth, underscoring the technology's strategic importance.

This flood of investment signals a deeper, more fundamental shift within the industry. The deployment of intelligent sensors on physical assets like turbines and pipelines—the domain of Operational Technology (OT)—is now inextricably linked with the data analytics, artificial intelligence, and software platforms that define Information Technology (IT). This convergence is forcing the breakdown of long-standing organizational silos. The challenges inherent in this transition, such as integrating modern software with legacy industrial control systems and securing newly connected OT assets from cyber threats, represent the primary friction points between these two worlds. Successfully navigating this landscape requires more than a technology project; it demands a profound organizational and cultural transformation, fostering new skill sets and collaborative models between previously disconnected IT and OT departments. This is the foundational strategic challenge that executives must lead.

2. How Are These Technologies Being Used in the Real World to Drive Value?

The strategic investment in IoT and Edge Computing is translating into tangible, high-value applications across the entire energy value chain, from generation and distribution to consumption. These use cases demonstrate a clear path from technological capability to measurable business outcomes.

From Theory to Practice: Tangible Use Cases

Smart Grids and Real-Time Energy Monitoring The concept of the smart grid moves beyond automated meter reading for billing purposes into a new realm of dynamic, intelligent energy distribution. By deploying a dense network of IoT-enabled smart meters and grid sensors, utility providers gain a real-time, high-resolution view of the entire distribution network. This allows them to dynamically balance supply and demand, proactively identify and isolate faults to prevent widespread outages, and minimize energy losses during transit. This level of granular control is the essential prerequisite for reliably integrating intermittent renewable energy sources, such as solar and wind, into the grid, ensuring stability even as the generation mix becomes more complex.

Predictive Maintenance for Critical Assets Predictive maintenance is arguably the flagship application for Industrial IoT, delivering the most dramatic and easily quantifiable return on investment. The traditional approaches—reacting to a failure after it occurs or performing scheduled maintenance based on fixed intervals—are either costly and disruptive or inefficient and wasteful. Predictive maintenance upends this model. IoT sensors continuously monitor the health of critical assets by tracking key indicators like vibration signatures, temperature fluctuations, and acoustic anomalies. This stream of data is fed into artificial intelligence and machine learning models, often running at the edge for immediate analysis, to detect subtle patterns that precede a failure. This allows maintenance teams to intervene proactively, scheduling repairs before a catastrophic breakdown occurs, thereby maximizing asset uptime and operational longevity. This approach is being applied to mission-critical equipment across the sector, from gas turbines in power plants to distribution pumps in oil and gas pipelines.

Automated and Optimized Operations Beyond preventing failures, IoT and Edge technologies are automating a host of previously manual and inefficient processes. Routine tasks like energy measurement and workflow monitoring can be fully automated, freeing up personnel to focus on higher-value strategic initiatives. In the context of energy consumption, this has a profound impact. Commercial and industrial buildings, for example, can leverage IoT sensors to track real-time occupancy, ambient light levels, and temperature. This data enables smart HVAC and lighting systems to automatically adjust their output, ensuring optimal conditions without wasting energy on empty rooms or during peak daylight hours. Such intelligent building management systems have demonstrated the ability to reduce energy consumption by up to 40-50%, a significant operational saving.

Enhanced Worker Safety and Sustainability The ability to monitor assets remotely has significant implications for workforce safety. By deploying IoT sensors in hazardous or hard-to-reach environments, such as offshore oil rigs or remote pipeline sections, companies can drastically reduce the need for manual inspections, minimizing employee exposure to risk. This remote visibility, combined with the efficiency gains from optimized energy consumption and the enhanced ability to integrate renewable sources, makes IoT and Edge powerful tools for achieving corporate Environmental, Social, and Governance (ESG) targets and demonstrating a commitment to sustainable operations.

These use cases reveal a strategic evolution that extends beyond operational efficiency. The granular data generated by these connected systems is enabling a fundamental shift in the industry's business model. Historically, energy companies have sold a commodity—kilowatt-hours of electricity, barrels of oil, or cubic feet of natural gas. The rich data streams from IoT are creating the opportunity to transition from selling a commodity to delivering a value-added service. For instance, utilities with smart meter data can offer customers personalized energy management services and dynamic pricing plans based on their unique consumption patterns. An equipment manufacturer can leverage predictive maintenance data from its turbines to offer "uptime-as-a-service," guaranteeing a certain level of performance and reliability rather than just selling the physical machine. In a fully realized smart grid, even commercial buildings can become active participants, using their intelligent management systems to sell excess energy back to the grid during periods of high demand. This transformation opens up entirely new and potentially lucrative revenue streams, changing the core value proposition from simple energy delivery to sophisticated energy management and guaranteed performance.

3. What Is the Realistic Financial Impact and ROI of an IoT-Driven Strategy?

For any executive considering a significant technology investment, the ultimate question is one of financial return. The data from early adopters and authoritative analyses in the energy sector provides a compelling and quantifiable business case, particularly in the realm of predictive maintenance and document management.

Hard Numbers for the Bottom Line

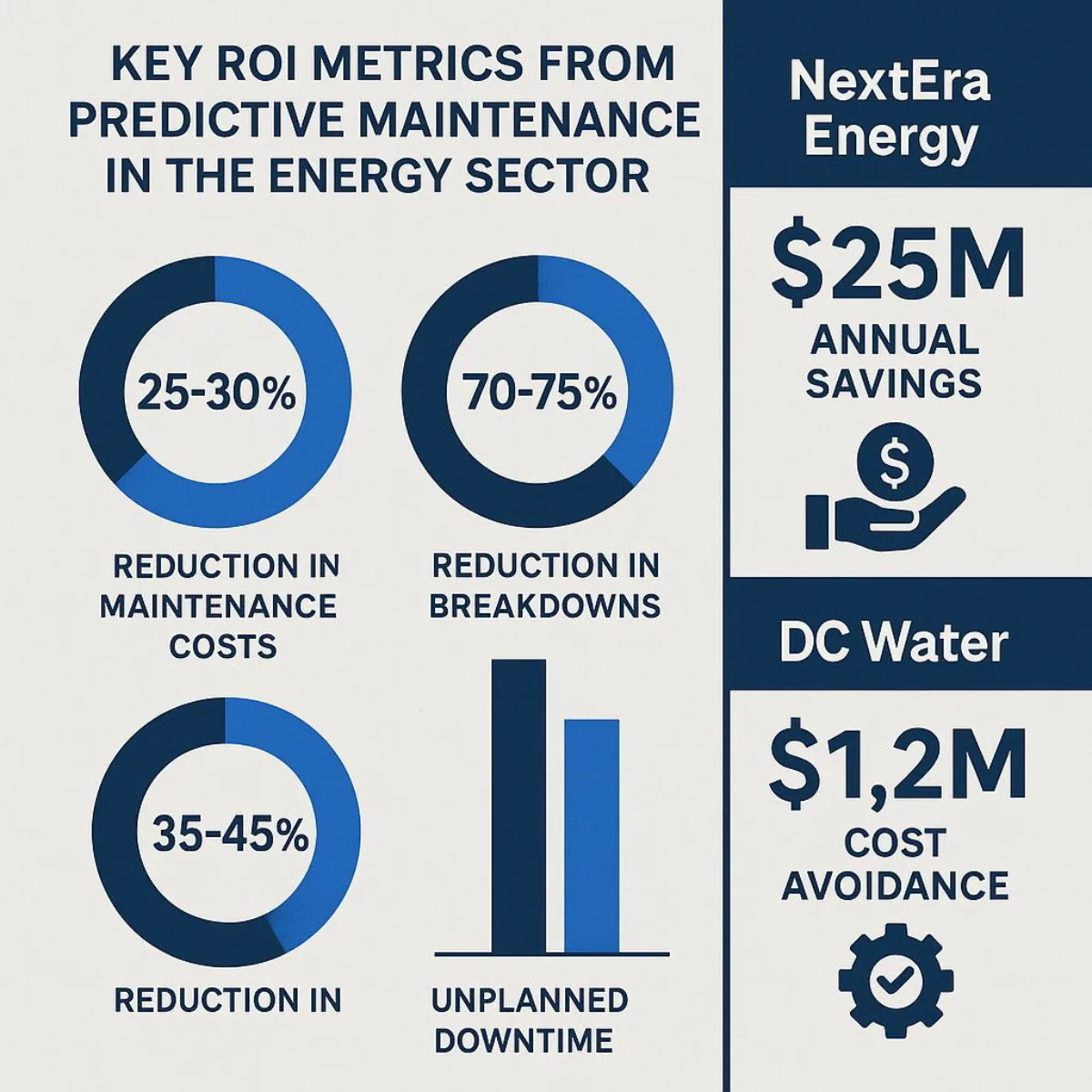

The financial benefits are not marginal; they represent a step-change in operational and maintenance efficiency. According to a comprehensive analysis by the U.S. Department of Energy, a properly implemented predictive maintenance program, powered by IoT data, consistently delivers staggering results: a 25-30% reduction in maintenance costs , a 70-75% decrease in asset breakdowns , and a 35-45% reduction in unplanned downtime . A separate study by McKinsey & Company corroborates these findings, estimating that this approach can increase overall equipment uptime by 5-15%.

These industry-wide statistics are validated by specific, high-impact corporate case studies:

- NextEra Energy , a major power utility, implemented an advanced predictive maintenance system across its gas turbine fleet. The program resulted in a 23% reduction in unplanned outages and generated $25 million in annual maintenance cost savings . In one documented instance, the system detected a subtle change in a vibration signature that indicated an impending bearing failure. This foresight allowed the company to schedule maintenance during a planned outage, avoiding a potential 14-day emergency shutdown that would have cost an estimated $3.2 million in lost generation revenue.

- DC Water , a leading water utility, deployed an AI-driven predictive system to monitor its vast underground infrastructure. The system successfully identified a developing main break 17 days before conventional methods would have detected it. This single proactive intervention enabled a planned repair instead of a disruptive emergency response, saving an estimated $1.2 million in repair costs and preventing a service outage for over 12,000 customers.

Crucially, the return on this investment is not a distant prospect. A detailed analysis by Deloitte found that the payback period can be remarkably swift. For targeted pilot projects focused on a company's most critical assets, a positive return on investment (ROI) is typically achieved within 9-12 months . For more comprehensive, system-wide deployments, the ROI timeline is generally 18-24 months .

| Metric | Proven Improvement (%) | Authoritative Source |

|---|---|---|

| Maintenance Cost Reduction | 25-30% | U.S. Department of Energy |

| Asset Breakdown Decrease | 70-75% | U.S. Department of Energy |

| Unplanned Downtime Reduction | 35-45% | U.S. Department of Energy |

| Production Increase | 20-25% | U.S. Department of Energy |

| Equipment Uptime Increase | 5-15% | McKinsey & Company |

| Case Study Highlight | NextEra Energy saved $25M annually and avoided a single $3.2M outage. |

Table 2: Proven ROI from Predictive Maintenance in the Energy Sector. Data from government and industry analysis, supported by corporate case studies, demonstrates significant and rapid financial returns.

These impressive financial returns are created by a powerful synergy between IoT and Edge Computing. While IoT sensors provide the raw data needed for analysis, it is the low-latency processing enabled by Edge Computing that truly unlocks the financial value. The ability to prevent a multi-million-dollar failure hinges on detecting an anomaly and reacting in real-time. Transmitting petabytes of high-frequency sensor data to a centralized cloud for analysis introduces inherent delays—latency that could be the difference between a proactive repair and a reactive disaster.

By processing data locally at the edge, organizations can achieve the millisecond-level response times necessary to act on predictive insights before a failure cascade begins. This directly maximizes the probability of achieving the cost savings and downtime reductions outlined in Table 2. Furthermore, this architecture creates a secondary financial benefit: by filtering and analyzing data locally, companies can significantly reduce the volume of data transmitted to the cloud, leading to substantial savings on bandwidth and cloud storage costs. Therefore, an investment in IoT without a corresponding investment in an edge strategy yields a suboptimal return. The two technologies are not merely complementary; they are financially synergistic, creating a positive feedback loop where faster processing leads directly to greater savings.

4. What Are the Biggest Hurdles to Implementation (And How Can We Overcome Them)?

While the potential returns are immense, the path to implementing a scalable and secure IoT and Edge solution is fraught with significant challenges. Acknowledging these hurdles is the first step toward building a robust and successful strategy.

Addressing Executive Concerns Head-On

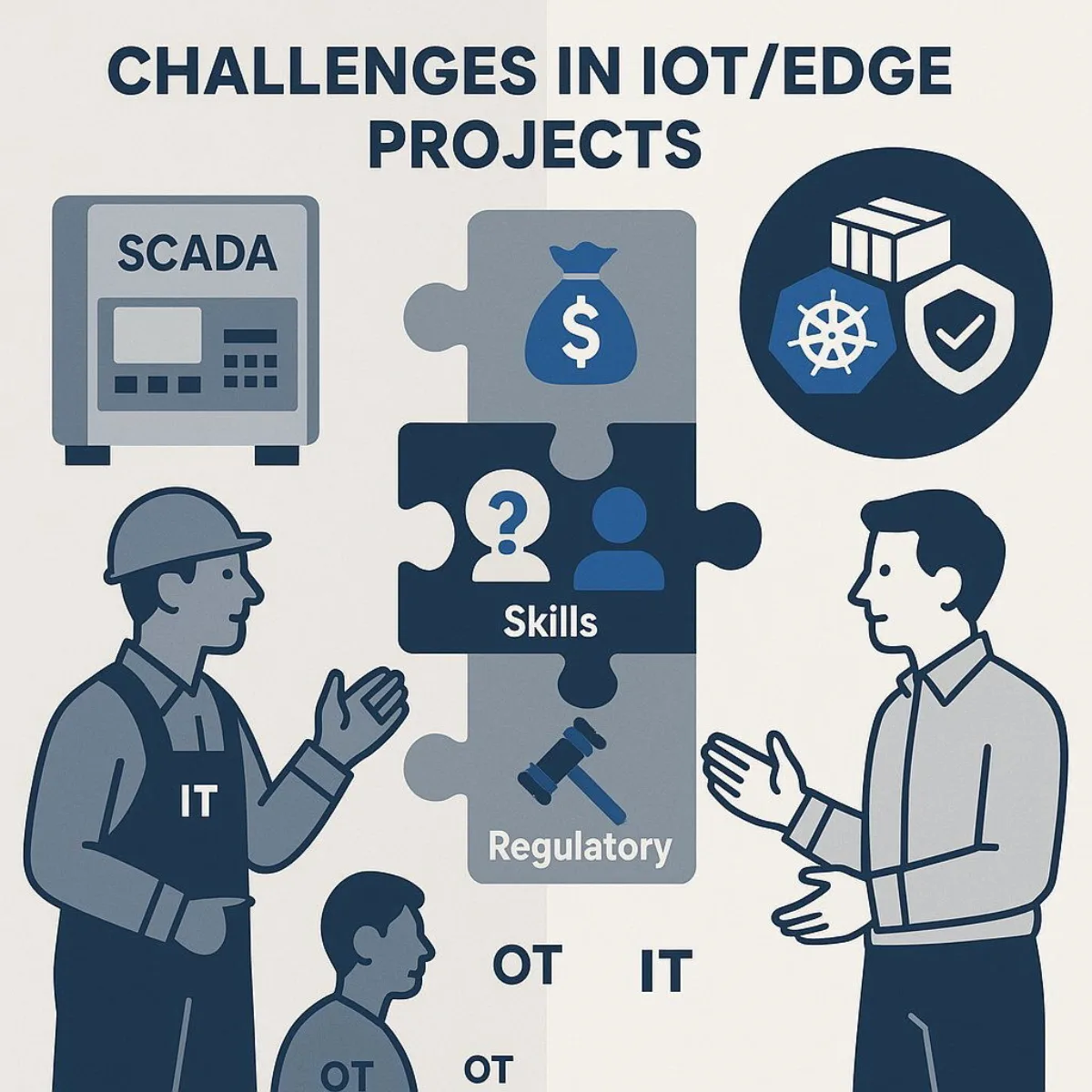

- Integration with Legacy Systems: A primary obstacle is the challenge of integrating modern IoT technologies with existing, often decades-old, operational technology. Much of the energy sector's critical infrastructure—from industrial controllers to SCADA systems—was not designed for interconnectivity. Retrofitting these "brownfield" environments to communicate with modern IT platforms is a complex engineering task.

- Cybersecurity Risks: Connecting previously isolated OT systems to corporate networks and the internet dramatically expands the potential attack surface for malicious actors. A successful cyberattack on critical energy infrastructure could have devastating consequences, making security a paramount concern for any deployment.

- Data Security and Sovereignty: The vast amounts of sensitive operational data generated by IoT devices raise critical questions about ownership, privacy, and governance. Organizations must ensure that their data handling practices comply with a complex web of regional and international regulations, especially when data is processed across multiple geographic locations in the cloud.

- High Initial Investment (CAPEX): The upfront cost for a large-scale deployment—including sensors, edge hardware, network upgrades, and software development—can be substantial. This initial capital expenditure can be a barrier for organizations, and it must be carefully weighed against the long-term operational expenditure (OPEX) savings and the financial benefits of increased uptime and efficiency.

- Cultural and Skill Gaps: The convergence of IT and OT requires a new blend of expertise. OT engineers, traditionally focused on mechanical and electrical systems, must become more adept with software and data. Conversely, IT professionals must learn to navigate the unique constraints and mission-critical demands of the industrial environment. Bridging this cultural and skills gap is essential for successful collaboration and implementation.

Overcoming these multifaceted challenges requires more than just selecting the right hardware; it demands a fundamental shift in architectural philosophy. A monolithic, proprietary, and inflexible solution designed for a single use case is destined to become a technological dead end. It cannot adapt to new security threats, integrate with future technologies, or scale across the enterprise. This is why the conversation in advanced industrial deployments has shifted decisively toward a more modern, flexible, and open architectural approach rooted in cloud-native principles and DevOps efficiency.

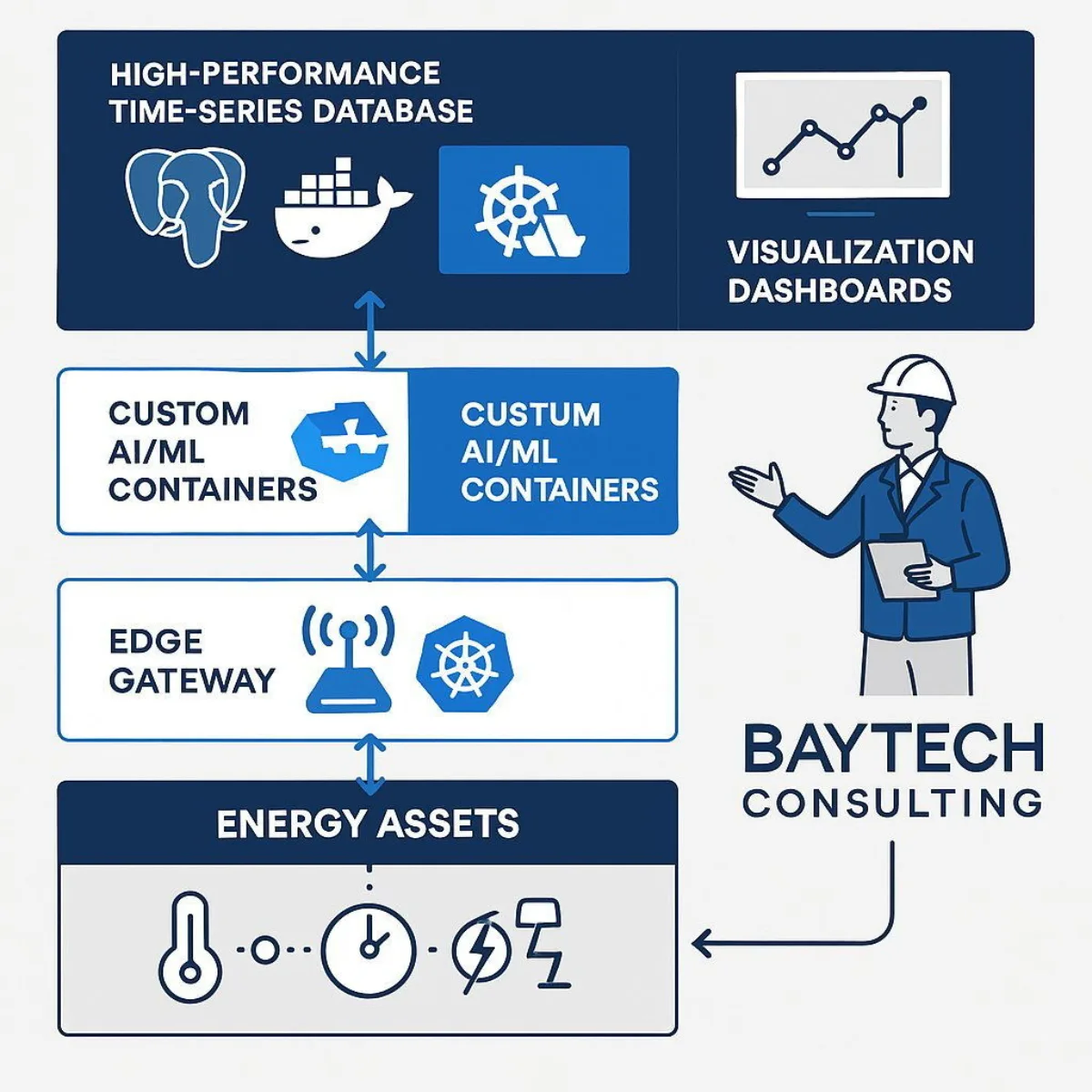

Leading energy companies are increasingly adopting containerization technologies like Docker and container orchestration platforms like Kubernetes to manage their distributed edge applications. A container packages an application and all its dependencies into a single, portable unit that can run consistently across any environment. Kubernetes is the management layer that automates the deployment, scaling, and operation of these containers across a fleet of devices, from a central data center to a remote edge gateway.

This architectural choice directly addresses the primary implementation hurdles. It provides a standardized way to deploy software on heterogeneous legacy and modern hardware, simplifying the integration challenge. It enables the enforcement of granular, policy-based security controls across the entire distributed system. It also allows for the independent, scalable updating of different software components (known as microservices), creating a resilient and adaptable platform. Therefore, the most critical strategic decision an executive can make is not which sensor to purchase, but to champion an architectural philosophy that embraces flexibility, scalability, and security by design. This is the key to future-proofing the investment and building a platform that can evolve with the business.

5. How Do We Build a Resilient and Scalable Solution? The Critical Role of Custom Software.

The unique and demanding nature of the industrial energy sector often renders generic, off-the-shelf IoT platforms inadequate. These one-size-fits-all solutions typically lack the flexibility to integrate with specialized legacy OT systems and cannot be tailored to the unique physics and failure modes of highly specific industrial equipment. This gap between generic platforms and specific operational realities is where a strategic partnership with a custom software development firm becomes not just beneficial, but essential.

The Case for a Strategic Partner

Building a truly effective industrial IoT and Edge solution requires a level of customization and deep integration that commodity products cannot provide. A firm like Baytech Consulting , which specializes in custom enterprise software for complex industrial applications, plays a pivotal role in bridging this gap and architecting a solution that delivers maximum value.

-

Seamless Systems Integration: The first challenge is creating a unified data fabric from a disparate collection of assets. Custom software acts as the critical "glue" that connects a diverse ecosystem of sensors, gateways, legacy SCADA systems, and cloud platforms into a single, cohesive, and manageable system. A partner like

Baytech Consulting possesses the specialized systems integration expertise required to orchestrate this complex interplay of hardware and software.

- Tailored Analytics and AI: The most powerful predictive insights do not come from generic algorithms. They come from AI and ML models that are meticulously trained on an organization's own unique, historical operational data. Baytech Consulting can develop and deploy these bespoke models as lightweight, containerized applications that run efficiently at the edge. This delivers real-time, context-aware intelligence that is precisely tuned to the specific failure modes and performance characteristics of an organization's critical assets.

- Modern, Scalable Architecture: Implementing a robust, secure, and manageable edge infrastructure using modern technologies like Docker and Kubernetes is a highly specialized discipline. It requires deep expertise not only in cloud-native engineering, but also in building automated Continuous Integration/Continuous Deployment (CI/CD) pipelines for distributed environments. Mastering Kubernetes at scale is at the heart of creating agile, enterprise-grade solutions. Baytech Consulting provides these essential skills, ensuring that the resulting solution is not only powerful on day one but also scalable and maintainable for years to come.

-

High-Performance Data Management: Industrial IoT applications generate a torrent of time-series data—a constant stream of timestamped readings from thousands of sensors. Standard relational databases are ill-equipped to handle this massive volume and velocity. Specialized solutions, such as the open-source PostgreSQL database enhanced with the TimescaleDB extension, are purpose-built for this challenge. They offer extremely high data ingestion rates, efficient data compression, and powerful analytical querying capabilities. An expert partner like

Baytech Consulting can architect and implement the correct data backend, ensuring the system's performance and scalability as data volumes grow exponentially.

The most effective way to engage such a partner and de-risk the investment is to begin with a tightly scoped pilot project. By focusing on a specific set of critical assets, an organization can prove the technology's value and demonstrate a clear ROI within the 9-12 month timeframe identified by industry analysts, building momentum and internal support for a broader, enterprise-wide rollout.

This approach highlights a crucial strategic realization: in the new energy landscape, the durable competitive advantage is not found in the hardware, which is rapidly becoming commoditized. Any organization can purchase sensors and edge gateways. The long-term, defensible advantage lies in the proprietary software, custom algorithms, and unique data sets that an organization develops. An energy company's decades of historical operational data is an invaluable and inimitable asset for training predictive AI models. Therefore, an investment in custom software development with a partner like

Baytech Consulting is not merely an implementation expense; it is a direct investment in the creation of a core intellectual property asset. This intelligent software layer—the "brain" that optimizes operations—will be the key differentiator in an increasingly efficient and data-driven industry.

6. What Does the Future Hold? Key Trends Shaping the Next Five Years (2025-2030)

The rapid pace of technological innovation ensures that the industrial IoT and Edge landscape will continue to evolve. Analysis of forward-looking reports from leading firms like Gartner, IDC, and Forrester provides a clear picture of the key trends that will define the next phase of this transformation.

Synthesizing Analyst Projections

- Hyper-Convergence of Technologies: The future is not about any single technology in isolation but about their seamless integration. The most advanced solutions will weave together IoT, Edge Computing, AI, 5G cellular connectivity, and Digital Twins into a single, powerful platform. The ultra-low latency and high bandwidth of 5G will unlock more sophisticated real-time control applications, while Digital Twins—virtual replicas of physical assets—will provide a rich environment for simulation, analysis, and optimization.

- From Predictive to Autonomous Operations: The role of AI at the edge is set to evolve dramatically. The current focus on predicting failures will give way to systems capable of autonomous action. These intelligent systems will not only forecast a potential problem but will also be able to self-optimize, self-configure, and self-heal in response to changing conditions, often without any human intervention.

- The Rise of Unified Edge Platforms: As organizations mature, they will move away from the current model of fragmented, single-use-case deployments. The trend is toward the adoption of unified, horizontal edge management platforms that can support a diverse range of applications across the entire enterprise. This shift reflects a strategic view of the edge as a core component of enterprise IT infrastructure. Gartner predicts that by 2025, a staggering 75% of all enterprise-generated data will be created and processed at the edge, up from just 10% in 2018.

- Intensified Focus on Security and Governance: As the scale and criticality of edge deployments grow, cybersecurity will become an even more urgent priority. The industry will see wider adoption of advanced security paradigms like Zero Trust Architecture, which assumes no user or device is inherently trustworthy and requires continuous verification. This will be coupled with the use of AI-powered threat detection systems specifically designed to monitor and protect distributed edge environments.

These trends reveal that the energy sector is not merely adopting technology; it is serving as a high-stakes proving ground for innovations that will have profound implications across the entire industrial landscape. The core challenge being solved in energy—the real-time management, monitoring, and optimization of distributed, mission-critical physical assets—is the same fundamental challenge faced in a multitude of other industries.

This makes the lessons learned and the architectural patterns perfected in the energy sector directly transferable. The predictive maintenance models used to prevent a $3 million turbine failure can be adapted to forecast the failure of a critical MRI machine in a hospital or even to detect financial fraud by identifying anomalous transactional patterns that deviate from the norm. The sophisticated load-balancing techniques developed to stabilize a city's power grid are now inspiring new models for real-time resource and energy management in large hospital facilities. Consequently, executives in the energy sector are not just solving their own operational problems; they are at the vanguard of a much broader industrial transformation. The platforms they build and the expertise they develop will set the standard for the future of the Industrial Internet of Things (IIoT). If you want to learn more about accelerating digital transformation and improving outcomes in similar complex environments, you’ll find our insights on digital-first patient engagement platforms for healthcare particularly relevant.

Conclusion: From Data to Dominance: Your Strategic Imperative in the New Energy Landscape

The evidence is clear and compelling: the transition to an operational model driven by the Internet of Things and Edge Computing is not a matter of 'if' but 'when' and 'how'. The financial data demonstrates proven, multi-million-dollar returns and rapid payback periods. The technology, from sensors and gateways to the sophisticated software that manages them, has matured into a robust and scalable ecosystem. The competitive pressures to improve efficiency, enhance resilience, and meet sustainability goals are mounting, making inaction a significant strategic risk.

This report has illuminated the path forward, addressing the critical questions that should be on every executive's agenda. The financial returns are not theoretical; they are documented, significant, and achievable within short timeframes. The implementation challenges—from legacy system integration to cybersecurity—are substantial but can be overcome with a modern, flexible architectural strategy rooted in cloud-native principles.

Successfully navigating this transformation requires a shift in mindset. The most critical investments are not in the hardware, but in the intelligent software layer that turns raw data into a defensible competitive advantage. This necessitates a partnership-driven approach, collaborating with specialists who can architect and build the custom solutions required to meet the unique demands of the industrial energy environment.

The ultimate goal extends beyond simply collecting data from the field. It is about fundamentally rewiring the organization's operational DNA to create a more predictive, efficient, and resilient enterprise. For the leaders who champion this change, this is not a technology project to be delegated, but a core business transformation to be led. The opportunity is to move beyond incremental improvements and achieve operational dominance in a new, intelligent energy era.

About Baytech

At Baytech Consulting, we specialize in guiding businesses through this process, helping you build scalable, efficient, and high-performing software that evolves with your needs. Our MVP first approach helps our clients minimize upfront costs and maximize ROI. Ready to take the next step in your software development journey? Contact us today to learn how we can help you achieve your goals with a phased development approach.

About the Author

Bryan Reynolds is an accomplished technology executive with more than 25 years of experience leading innovation in the software industry. As the CEO and founder of Baytech Consulting, he has built a reputation for delivering custom software solutions that help businesses streamline operations, enhance customer experiences, and drive growth.

Bryan’s expertise spans custom software development, cloud infrastructure, artificial intelligence, and strategic business consulting, making him a trusted advisor and thought leader across a wide range of industries.