Transforming Construction: The Executive Blueprint for IoT Success

August 24, 2025 / Bryan Reynolds

The Hard Hat Revolution: An Executive's Guide to IoT in Construction

The construction industry is a titan of the global economy, representing an astonishing 13% of the world's GDP. Yet, for an industry of such immense scale and importance, its productivity growth has been nearly flat for the last two decades, inching forward at a mere 1% annually. For executives in the field, this statistic is the backdrop to a daily battle against persistent, razor-thin margins and a host of deeply entrenched challenges. Project delays, budget overruns, a critical labor shortage now estimated at 350,000 workers, and staggering annual losses from theft ranging from $400 million to $1 billion are not abstract risks—they are fundamental threats to profitability and project delivery.

For decades, these issues have been managed through experience, intuition, and sheer force of will. But a new paradigm is emerging. The Internet of Things (IoT) is no longer a futuristic concept discussed in tech circles; it is a powerful, practical business lever being deployed on job sites today. It represents a fundamental shift from making decisions based on yesterday's reports to commanding a project with real-time, data-driven intelligence. This is not about adding gadgets to the job site; it's about transforming every asset, from a generator to a worker's helmet, into an intelligent node in a network that provides unprecedented visibility and control. For construction leaders, understanding this shift is no longer optional—it's the key to building a competitive advantage in an industry on the brink of a technological revolution.

What is Construction IoT, and Why Should I Care Now?

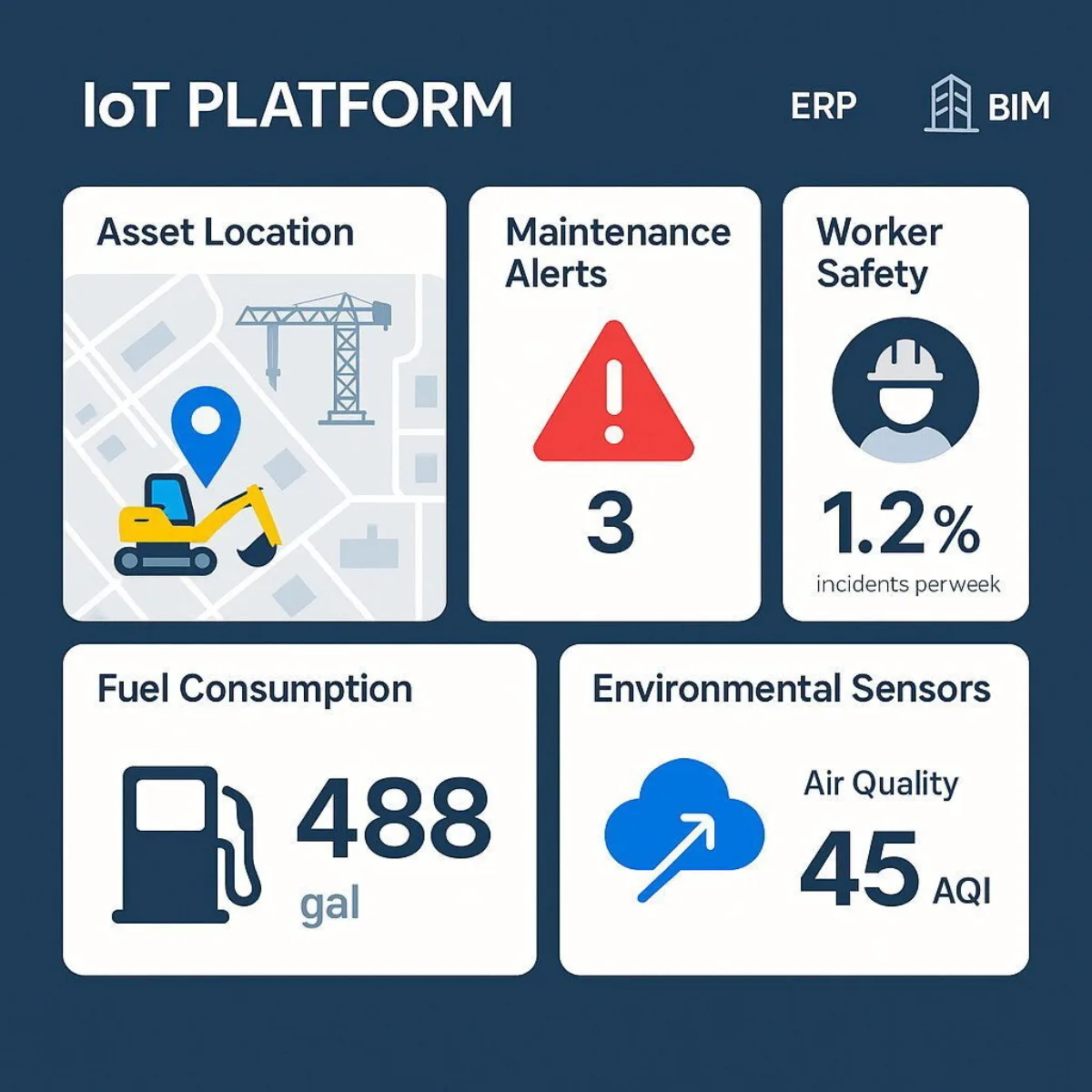

At its core, the Internet of Things in construction is a network of physical objects on a job site—tools, heavy machinery, building materials, and even workers' personal protective equipment (PPE)—that are embedded with sensors, software, and other technologies for the purpose of connecting and exchanging data over the internet. In simple terms, it gives a digital voice to every physical asset. A crane can report its engine temperature and stress levels. A pallet of drywall can announce its arrival and location. A smart helmet can signal if a worker has experienced an impact. This constant stream of data, when collected and analyzed, provides a live, digital replica of the entire construction site, turning raw information into actionable insights.

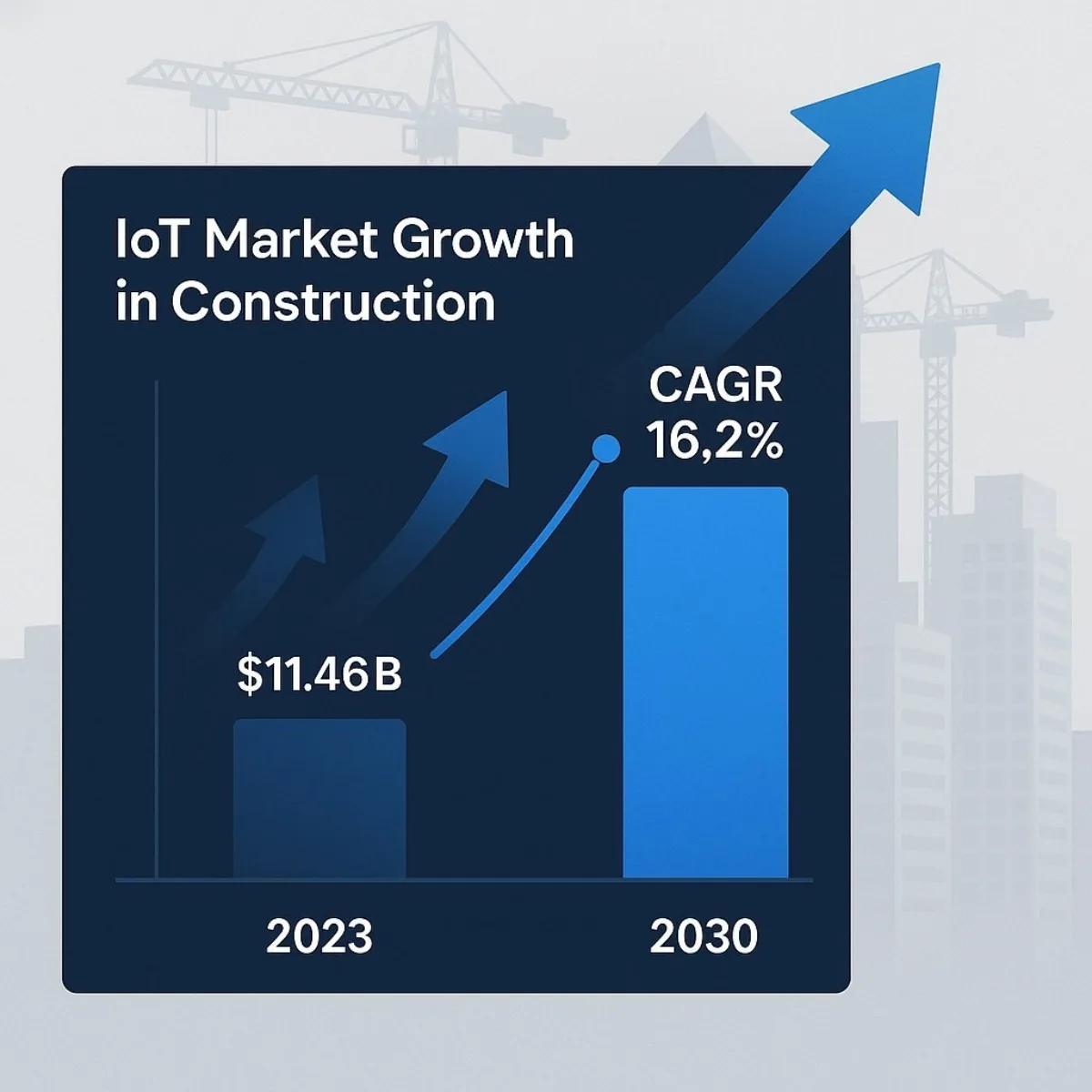

The critical question for any executive is, "Why is this urgent now?" The answer lies in the undeniable market momentum, which signals a permanent industry transformation. The global IoT in construction market, valued at $11.46 billion in 2023, is projected to surge to over $34 billion by 2031, expanding at a compound annual growth rate (CAGR) of 16.2%. This is not a niche trend; it is a market-wide tectonic shift. Furthermore, a recent survey revealed that 76% of construction business operators now consider the adoption of new technology a core part of their strategic vision, indicating that a majority of competitors are actively investing in these capabilities.

This explosive growth is not happening in a vacuum. It is a direct and forceful response to the escalating pressures that define the modern construction landscape. The industry is not adopting IoT because it is fashionable; it is embracing it because the traditional ways of managing projects are becoming financially and operationally unsustainable. Faced with rising material costs, persistent labor shortages, and increasing project complexity, firms are turning to technology not as a luxury, but as a fundamental tool for survival and growth. The data shows that the industry has reached a tipping point where the risk of inaction now far outweighs the perceived risk of investing in new technology.

What are the Most Significant Bottom-Line Benefits of an IoT-Enabled Job Site?

For any technology investment to be viable, it must deliver tangible returns. IoT in construction excels by directly addressing the three pillars of executive concern: productivity, safety, and cost control. The benefits are not theoretical; they are quantifiable and are already being realized by early adopters.

Boosting Productivity and Slashing Downtime

One of the most immediate and high-impact applications of IoT is in predictive maintenance. By embedding sensors in heavy equipment like cranes, excavators, and generators, firms can monitor critical indicators such as vibration, temperature, and fluid levels in real time. Advanced analytics can then detect subtle anomalies that precede mechanical failure, allowing maintenance to be scheduled proactively rather than in response to a costly, project-halting breakdown. The financial impact is profound: studies show predictive maintenance can reduce unplanned downtime by up to 50% and cut associated maintenance costs by 10-40%. In one real-world example on a London skyscraper project, vibration sensors on a tower crane's motor flagged a deteriorating bearing, allowing for a planned replacement during off-hours and preventing a potential catastrophic failure that would have crippled the project schedule.

Beyond individual assets, IoT optimizes the entire site's workflow. Real-time data from across the project allows managers to identify bottlenecks, reallocate crews and equipment dynamically, and automate manual processes like progress reporting. This leads to more efficient use of every resource on site, with some case studies demonstrating a 10-15% improvement in overall asset utilization. To learn how artificial intelligence is broadly transforming construction workflows through automation, see AI in Construction: How Artificial Intelligence Is Transforming Projects from Design to Delivery.

Creating a Safer, More Compliant Work Environment

Safety is a moral imperative and a significant financial variable in construction. The industry's sobering statistic of accounting for roughly one in five workplace deaths is a major deterrent to attracting and retaining talent in a tight labor market. IoT provides a powerful suite of tools to transform site safety from a reactive, compliance-based activity to a proactive, preventative system.

Smart wearables, such as sensor-equipped helmets and vests, are at the forefront of this change. These devices can monitor workers' vital signs to detect heat stress or fatigue, automatically register a fall and alert supervisors, and create virtual "geofences" that trigger an alarm if a worker enters a hazardous zone, such as the swing radius of an excavator. The results are dramatic. Early case studies from sites that have deployed comprehensive wearable safety systems report reductions in accidents and injuries by as much as 40%. This is complemented by environmental sensors that monitor air quality for dust or toxic gases and track noise levels, helping to ensure regulatory compliance and contributing to a reported 15% drop in work-related illnesses.

Gaining Control Over Project Costs

IoT provides a new level of precision in managing the financial variables of a project. Asset tracking, using a combination of GPS, RFID, and Bluetooth tags, gives managers a real-time inventory of every tool and piece of equipment on a large, complex site. This drastically reduces time wasted by crews searching for misplaced items and provides a powerful deterrent against theft, directly addressing the industry's billion-dollar annual loss problem.

Resource management is also optimized. IoT enables just-in-time delivery of materials, ensuring they arrive precisely when needed, which minimizes on-site storage requirements, reduces waste, and prevents delays. Similarly, smart sensors on fuel tanks can monitor consumption, automate refueling schedules, and prevent theft, reining in one of the largest operational expenses on any site. When these efficiencies are combined, the overall impact is substantial, with research suggesting that IoT-enabled projects can achieve total cost reductions of up to 29%.

Crucially, these benefits do not exist in isolation; they create a virtuous cycle. A safer worksite, enabled by wearables, leads to fewer accidents, which in turn lowers insurance premiums and prevents costly project shutdowns. This enhanced safety record also improves worker morale and becomes a selling point for attracting scarce talent, which directly boosts productivity. Likewise, a predictive maintenance alert that prevents an engine failure is simultaneously a productivity win, a safety event averted, and a massive cost saving. This "flywheel effect," where an investment in one area generates compounding returns across the entire operation, is what makes a holistic IoT strategy so powerful.

How is IoT Actually Being Used in the Field Today?

Moving from benefits to practical application, IoT is being deployed across construction sites in several key areas, each designed to solve a specific, high-cost business problem. These use cases demonstrate the technology's versatility and its ability to generate value throughout the project lifecycle.

| Use Case | Business Problem Addressed | Key Benefit & Statistic | The Critical Role of Custom Software |

|---|---|---|---|

| Predictive Maintenance for Heavy Equipment | Unplanned downtime, high emergency repair costs, safety risks from equipment failure. | Reduces downtime by up to 50%; Extends asset lifespan. | Ingests diverse sensor data (vibration, thermal, oil quality) into a single dashboard. Runs machine learning algorithms to flag anomalies specific to a company's fleet. Integrates with existing maintenance workflow/ERP systems. |

| Asset & Tool Tracking | Wasted labor searching for items, project delays from missing equipment, high costs from theft ($400M-$1B annually). | Reduces search times by up to 30%; Increases operational efficiency by 25%. | Creates a unified map of all assets, regardless of tag type (GPS, RFID, BLE). Sets up custom geofencing rules and alerts. Provides historical data for utilization analysis and loss prevention. |

| Worker Safety Wearables | High accident rates (1 in 5 workplace deaths), heat stress/fatigue, unauthorized access to hazardous zones. | Reduces on-site injuries by up to 40%. | Aggregates real-time data from hundreds of workers. Establishes personalized health baselines and triggers intelligent alerts. Integrates with site-wide emergency response protocols. |

| Fleet Management & Telematics | High fuel costs, inefficient routing, unauthorized vehicle use, excessive wear and tear. | Saves up to 15% on transport costs; Optimizes routes and reduces idle time. | Combines GPS data with engine diagnostics and fuel sensors. Provides dashboards for analyzing fleet efficiency, driver behavior, and maintenance needs. Integrates with dispatch and scheduling systems. |

| Remote Site Monitoring & Security | Lack of visibility on multiple projects, slow progress verification, theft and vandalism after hours. | Provides 24/7 visibility; Speeds up incident resolution and deters theft. | Integrates live video feeds with sensor data (e.g., motion, access control). Uses AI for intelligent alerts (e.g., person vs. animal). Creates automated time-lapses for progress reporting and stakeholder updates. |

While each of these applications provides standalone value, their true power is unlocked when the data streams are integrated. A first-level analysis sees tracking a tool or monitoring an engine as individual efficiency gains. A more sophisticated understanding reveals that the greatest value comes from analyzing the interactions between them.

For instance, knowing a worker's precise location from their smart helmet is useful. Knowing a dump truck's location from its telematics system is also useful. But when a custom software platform combines these two data streams, it can generate an automatic proximity alert when the worker and the truck are on a potential collision course, preventing an accident before it happens. Similarly, when an RFID tag signals that a specific shipment of steel beams has arrived on site, the platform can automatically update the project schedule in the ERP system, notify the structural crew via a mobile app, and release the payment to the vendor. This level of system-wide intelligence and automation—where disparate events trigger coordinated, cross-departmental actions—is impossible with a collection of siloed, off-the-shelf apps. It requires a central software brain capable of understanding the complex, interconnected workflows of a real job site.

For construction firms aiming to go beyond isolated solutions, it’s valuable to understand custom bidding software advantages in construction—which have similar integration demands—and how unified data can drive better outcomes.

What are the Real-World Challenges of IoT Adoption (And How Do We Solve Them)?

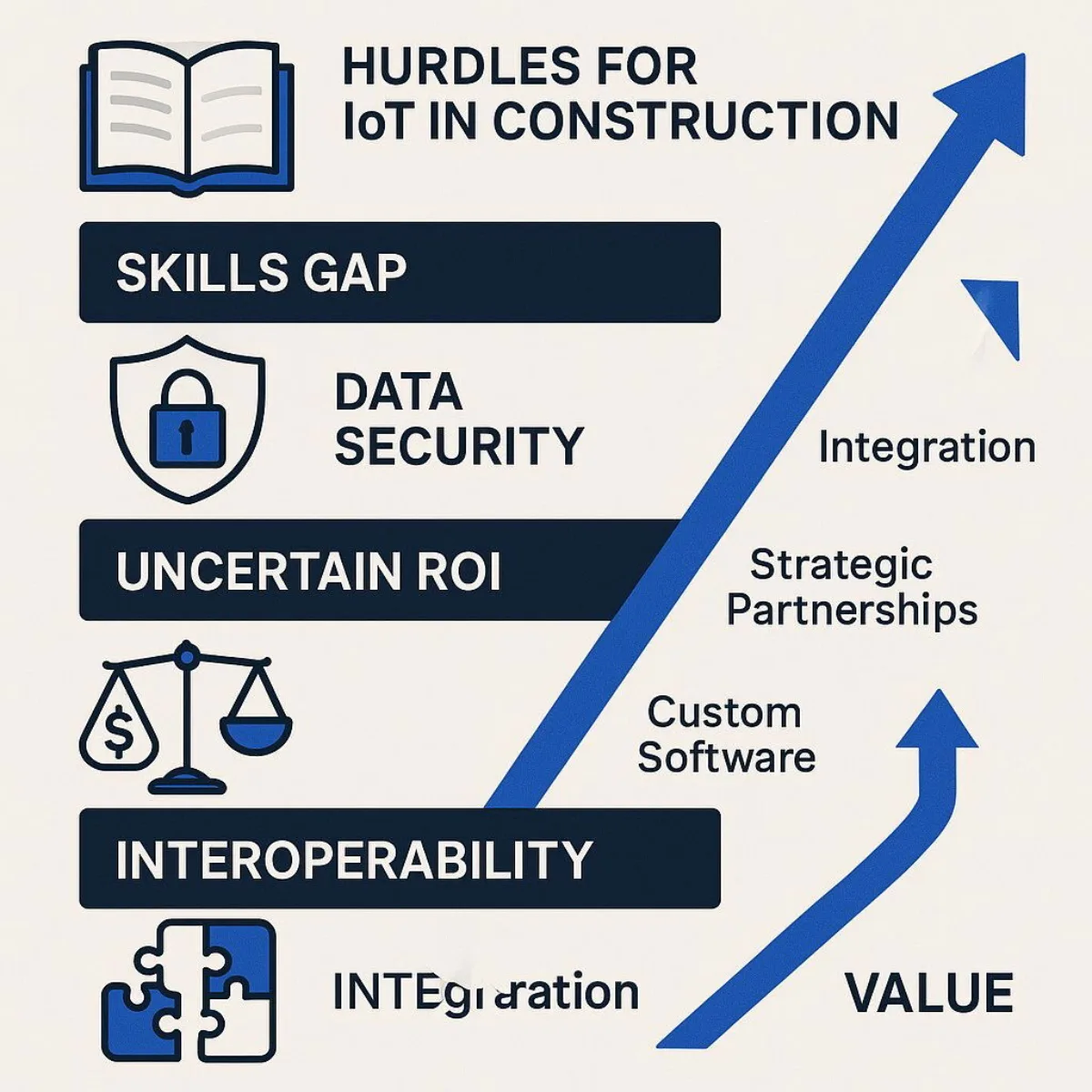

Despite the compelling benefits, executives are right to be cautious. The path to a connected job site is not without its challenges, and acknowledging them is the first step toward overcoming them. The most common concerns include:

- Lack of Knowledge & Skills Gap: Many construction firms, particularly small and mid-sized ones, lack the in-house technical expertise to properly evaluate, deploy, and manage complex IoT systems. There is a legitimate fear of the unknown and a well-documented shortage of workers trained to handle these new technologies.

- Data Security & Privacy: Connecting thousands of devices to the internet creates new vulnerabilities. Protecting sensitive project data, intellectual property, and worker information from cybersecurity threats is a paramount concern that requires robust security protocols from day one.

- Uncertain ROI: A recent World Economic Forum report cited "uncertain return on investment" as one of the top three barriers to IoT adoption. Business leaders are wary of making significant capital investments without a clear, predictable path to a positive financial return.

- Interoperability & Integration: This is the central, most critical challenge that often fuels all the others. A typical construction site is a heterogeneous environment with equipment, tools, and vehicles from dozens of different manufacturers. The sensors from a Caterpillar excavator do not natively communicate with the telematics in a Ford truck or the RFID tags on a pallet of materials. Without a way to bridge these gaps, companies are left with a collection of isolated data silos, making a unified view of the operation impossible.

Attempting to solve these problems piecemeal is inefficient and often fails. The skills gap becomes unmanageable when staff must learn ten different software interfaces. Security is a nightmare when every device represents a separate potential point of failure. And proving ROI is impossible when the data needed for analysis is fragmented across incompatible systems. For more insights and a CTO’s checklist for addressing integration versus rapid deployment, see Balancing customization vs. speed with low-code and custom software.

The solution lies in addressing the root cause: the integration problem. This is where a strategic partnership with a specialist firm becomes critical. A custom software development partner like Baytech Consulting focuses on building the central nervous system for the connected job site. They specialize in developing a custom IoT software platform that acts as a universal translator, ingesting data from any sensor, machine, or system, regardless of the manufacturer. This data is then normalized and unified into a single, intuitive dashboard—the "single source of truth" for the entire project.

This custom platform approach de-risks the entire IoT initiative. It solves the interoperability problem by design. It simplifies the user experience, allowing existing project managers and superintendents to leverage powerful analytics without needing to become data scientists, thus addressing the skills gap. Most importantly, by creating a single, comprehensive data lake for the entire operation, it enables the deep analysis required to track KPIs, measure efficiencies, and definitively prove ROI. The biggest risk in IoT adoption isn't choosing the wrong sensor; it's failing to have a coherent strategy for the data. The data shows that the software and services segment of the IoT market is where the most value is created, holding the largest market share because it is the software that transforms raw sensor readings into business intelligence.

Notably, behind the success of these platforms are evolving trends in AI-powered software development. The latest methods in integrating AI into software processes help construction firms accelerate innovation and successfully govern risk as they adopt digital solutions.

How Do I Get Started and Ensure a Positive ROI?

The prospect of a full-scale digital transformation can be daunting. The key is to start with a pragmatic, phased approach that minimizes risk and builds momentum through demonstrable wins.

Step 1: Start with a Single, High-Impact Problem

Resist the urge to "boil the ocean." Instead of a massive, site-wide deployment, identify the single most acute and costly pain point in the operation. Is it the excessive cost of replacing stolen hand tools? Is it the unpredictable maintenance budget for the crane fleet? Is it the project delays caused by late material deliveries? By focusing a pilot project on solving one specific, measurable problem, the scope becomes manageable, and the ROI becomes simple and unambiguous to calculate.

For energy sector leaders wrestling with similar digital hurdles, the transformation can begin with a single process as well—read how custom document management systems transform energy operations for a concrete blueprint.

Step 2: Select the Right Tools for That Job

Once the business problem is clearly defined, the hardware selection becomes much more straightforward. If the problem is tracking large assets across remote sites, GPS trackers with low-power wide-area network (LPWAN) connectivity are the logical choice. If the goal is to manage tool inventory within a designated laydown yard, more affordable Bluetooth or RFID tags may be sufficient. The key is to let the business need dictate the technology, not the other way around.

And as you evaluate data options, remember that a true competitive edge comes from operationalizing information. Learn how unlocking corporate knowledge using AI can help construction and project managers leverage scattered documentation, contracts, and specifications.

Step 3: Partner for the Platform Before You Scale

This is the most critical strategic decision in the process. While a small pilot might function with a standalone, off-the-shelf application, this approach creates a dead end. Scaling an IoT initiative across multiple projects and use cases requires a robust, flexible, and integrated software platform.

Engaging a partner like Baytech Consulting at the pilot stage ensures that the initial solution is built on an architecture designed for growth. An expert partner will not only solve the immediate problem but will do so using a scalable framework that can easily accommodate future use cases. They will build the foundation that can later integrate safety data, fleet telematics, environmental monitoring, and more, all while ensuring seamless integration with existing enterprise systems like ERP and Building Information Modeling (BIM) software. This foresight prevents the costly and disruptive scenario of having to rip-and-replace a patchwork of siloed systems two years down the line. The true ROI of a successful pilot is not just the immediate cost savings it generates, but the creation of a future-proof data infrastructure that will serve as the backbone for the company's digital operations for years to come.

For a deeper look at the transformative gains of software-powered integration in related industries, explore how digital-first software is changing patient engagement and ROI in healthcare—the challenges and solutions frequently map to construction technology initiatives as well.

Your Next Steps Toward a Smarter Job Site

The construction industry is at a digital inflection point. The data is clear: the Internet of Things is no longer an experiment but a proven, powerful tool for driving productivity, enhancing safety, and securing profitability in an increasingly competitive landscape. The journey from a traditional to a connected job site can seem complex, but the path forward is clear. The key to unlocking the immense value of IoT lies not in the sensors themselves, but in the intelligent software platform that turns a torrent of data into clear, decisive action.

The journey to a connected job site begins with a single, strategic conversation. To understand how this technology can be tailored to solve your company's unique challenges, it is essential to engage with experts who bridge the gap between the physical world of construction and the digital world of data.

Contact the experts at Baytech Consulting for a complimentary IoT readiness assessment. We'll help you identify the highest-impact pilot project for your business and map out a clear, pragmatic path to a measurable return on investment.

Supporting Links

- For a broad overview of industry trends: https://www.iotforall.com/construction-iot-trends-2025

- For a deeper look at safety applications: https://www.gallagherbassett.com/news-and-insights/2025/apr/the-role-of-wearables-and-the-iot-in-enhancing-construction-site-safety/

- For understanding IoT challenges and ROI: https://bridgera.com/how-can-organizations-calculate-the-roi-on-their-iot-solutions/

About Baytech

At Baytech Consulting, we specialize in guiding businesses through this process, helping you build scalable, efficient, and high-performing software that evolves with your needs. Our MVP first approach helps our clients minimize upfront costs and maximize ROI. Ready to take the next step in your software development journey? Contact us today to learn how we can help you achieve your goals with a phased development approach.

About the Author

Bryan Reynolds is an accomplished technology executive with more than 25 years of experience leading innovation in the software industry. As the CEO and founder of Baytech Consulting, he has built a reputation for delivering custom software solutions that help businesses streamline operations, enhance customer experiences, and drive growth.

Bryan’s expertise spans custom software development, cloud infrastructure, artificial intelligence, and strategic business consulting, making him a trusted advisor and thought leader across a wide range of industries.