AI in Construction: How Artificial Intelligence Is Transforming Projects from Design to Delivery

August 09, 2025 / Bryan ReynoldsBuilding the Future: How AI is Answering the Construction Industry's Toughest Questions

The construction industry has long been one of the least digitized sectors, a reality that carries a staggering price tag. In the UK alone, avoidable errors cost the industry an estimated œ10 billion to œ25 billion (approximately $12 billion to $30 billion) every single year. For executives, this isn't just a rounding error on a balance sheet; it's a massive, systemic drag on productivity and profitability, fueled by fundamental inefficiencies in planning, execution, and management. These are the persistent, costly questions that have plagued the industry for decades: How do we stop budget overruns? How do we prevent schedule delays? How do we make jobsites safer? How do we build better, faster, and for less?

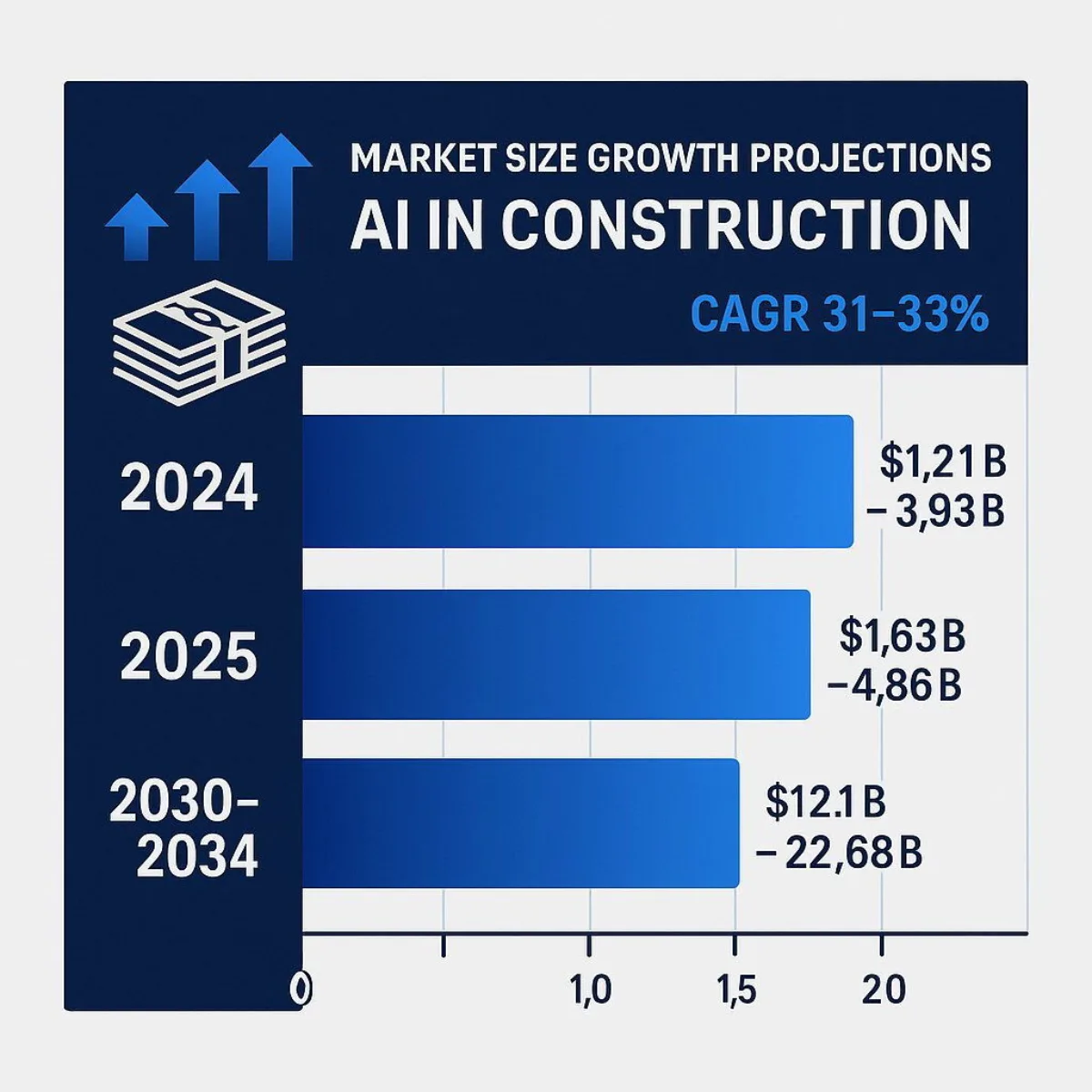

For the first time, a practical answer is emerging. Artificial Intelligence (AI) is moving out of the research lab and onto the job site, offering a suite of powerful tools designed to tackle these deeply entrenched problems. This is not a distant, futuristic concept; it is a tangible technological shift happening today. The global market for AI in construction is a testament to this transformation, with projections showing explosive growth that signals a fundamental reshaping of the industry. For leaders, the question is no longer

if AI will impact their business, but how soon and how deeply .

| Global AI in Construction Market Growth | |

|---|---|

| 2024 Market Size | $1.21 Billion - $3.93 Billion |

| 2025 Projected Size | $1.63 Billion - $4.86 Billion |

| 2030-2034 Projected Size | $12.1 Billion to $22.68 Billion |

| Compound Annual Growth Rate (CAGR) | ~31-33% |

A chart illustrating the projected growth of the global AI in construction market, demonstrating the rapid adoption and investment in this technology.

The immense financial burden of errors is not merely a symptom of isolated mistakes but a direct consequence of the industry's core data problem. Construction projects generate a colossal amount of fragmented data—photos, daily reports, Building Information Modeling (BIM) models, sensor readings, and change orders—much of which remains siloed and unused. Traditional methods are incapable of processing this deluge of information effectively, leading to poor communication, missed design conflicts, and reactive decision-making, which are the primary sources of error. AI's fundamental value proposition is its ability to finally structure, analyze, and extract actionable intelligence from this previously dark data. It reframes AI from a simple efficiency tool into a strategic solution for the industry's most expensive, long-standing challenges.

This report, guided by the "They Ask You Answer" approach, will provide executives with a comprehensive, honest, and transparent guide to AI's role in construction. We will address the most pressing questions leaders are asking, from the tangible benefits and significant challenges to the practical steps for adoption and the real-world risks of new phenomena like AI "hallucinations."

How is AI Transforming the Construction Industry? From Blueprints to Bulldozers

Artificial intelligence is not a single technology but a collection of capabilities—including machine learning, computer vision, natural language processing, and generative AI—that are being applied across the entire construction value chain. From the earliest design concepts to the final operational phase of a building, AI is introducing a level of precision, foresight, and automation that was previously unattainable.

Pre-Construction and Design: Building It Right, Digitally, First

The most significant and costly errors often originate in the pre-construction phase. AI is transforming this stage from a series of linear, manual steps into a dynamic, data-driven process of optimization and risk mitigation.

Generative Design and BIM Integration: One of the most revolutionary applications is generative design, where AI algorithms explore thousands of potential design iterations based on a set of predefined constraints such as cost, materials, structural loads, and energy efficiency. Instead of an architect manually creating a handful of options, the AI co-creates an entire universe of optimized solutions, allowing the project team to select the best possible outcome. When this capability is integrated with Building Information Modeling (BIM), the benefits are magnified. AI can analyze complex 3D models and automatically flag potential clashes between structural, mechanical, electrical, and plumbing (MEP) systems

before a single shovel hits the ground. This proactive conflict detection dramatically reduces the risk of expensive and time-consuming rework during the construction phase.

Automated Takeoffs and Cost Estimation: The process of quantity takeoff—manually measuring and counting materials from blueprints—is notoriously slow and prone to human error. AI is fundamentally changing this. AI-powered tools can analyze architectural plans and automatically generate a complete and accurate bill of quantities (BOQ) in a matter of minutes, a task that can take human estimators days or even weeks. This technology has been shown to accelerate the estimation process by as much as 80% while achieving up to 98% accuracy. Beyond simple counting, AI models analyze historical data from thousands of past projects to produce far more accurate cost estimates. They can account for complex variables that human estimators might overlook, such as regional material price fluctuations, seasonal labor availability, and market conditions, thereby providing a more reliable financial forecast and mitigating the risk of budget overruns.

On-Site Execution: The Rise of the Intelligent Jobsite

On the jobsite, AI is acting as a new set of eyes and ears, enhancing safety, monitoring quality, and automating physically demanding tasks.

Real-Time Safety Monitoring: Safety is a paramount concern in construction, and AI offers a powerful new layer of protection. Using computer vision, AI systems analyze live video feeds from on-site cameras to detect safety hazards in real-time. These systems can automatically identify workers who are not wearing the required Personal Protective Equipment (PPE), flag unauthorized personnel entering restricted or hazardous zones, and spot unsafe operating practices for heavy machinery. When a potential hazard is detected, an alert is sent instantly to the site manager, enabling proactive intervention before an accident occurs. This shift from reactive incident reporting to proactive hazard prevention has been shown to reduce on-site accidents by a remarkable 25-40%.

Quality Control and Progress Monitoring: The combination of drones, robotics, and AI is revolutionizing quality assurance. Drones capture high-resolution imagery of the jobsite, which AI algorithms then compare against the project's BIM models and construction schedule. This process automates progress tracking, providing stakeholders with a precise, real-time understanding of the project's status. More importantly, it enables early defect detection. The AI can identify subtle issues like structural misalignments, improper rebar spacing, or incorrect installations that might be missed by the human eye, allowing for correction before they become major problems and reducing rework costs by as much as 25%.

Autonomous Machinery and Robotics: While still in the early stages of adoption, AI-powered robotics are beginning to handle some of construction's most repetitive, physically demanding, and hazardous tasks. Autonomous or semi-autonomous bulldozers can prepare jobsites, robotic arms can lay bricks or perform welds with superhuman precision and consistency, and automated vehicles can transport materials across large sites. This not only boosts productivity and quality but also enhances safety by removing human workers from dangerous environments and freeing them to focus on more complex, higher-value tasks.

Project and Back-Office Management: The AI-Powered Command Center

Behind the scenes, AI is streamlining the complex administrative and managerial workflows that underpin every construction project.

Predictive Scheduling and Resource Allocation: Traditional project scheduling, often done with static Gantt charts, is brittle and struggles to adapt to the dynamic reality of a construction site. AI transforms scheduling into an intelligent, predictive process. By analyzing vast datasets—including historical project performance, current resource availability, supply chain logistics, and even weather forecasts—AI can generate optimized project schedules. When disruptions inevitably occur, such as a delayed material delivery, the AI system can automatically recalculate timelines and suggest the most efficient way to reallocate resources to minimize downtime and keep the project on its critical path.

Intelligent Document Management: A typical construction project is buried under a mountain of documents: contracts, RFIs, change orders, daily reports, blueprints, and permits. Professionals can spend up to 35% of their time on non-productive activities like searching for this information. AI leverages Natural Language Processing (NLP) and Optical Character Recognition (OCR) to solve this problem. It can automatically digitize, categorize, and extract key information from thousands of documents, making critical data instantly searchable and accessible. For example, a project manager could ask a system in plain English, "Show me all RFIs related to the HVAC system in Phase 2," and receive an answer in seconds. This capability is a massive productivity booster and reduces the risk of decisions being made with outdated or incomplete information.

The cumulative effect of these transformations is a shift from a reactive, experience-based management style to a proactive, data-driven one. The following table provides a clear comparison of how AI is fundamentally changing core construction processes.

| Aspect | Traditional Method | AI-Powered Method | Key Outcomes |

|---|---|---|---|

| Project Scheduling | Manual Gantt charts; static plans; reactive adjustments to delays. | AI-driven dynamic scheduling; predictive analytics; automated resequencing. | Reduced project delays, optimized resource flow, improved timeline accuracy. |

| Cost Estimation | Manual takeoffs from blueprints; spreadsheet-based calculations; high potential for human error. | Automated quantity takeoffs from digital plans; analysis of historical project data. | 80% faster estimation process, up to 98% accuracy, fewer budget overruns. |

| Safety Management | Manual site inspections; periodic safety meetings; reactive incident reporting. | Real-time computer vision monitoring; predictive hazard alerts; PPE compliance checks. | 25-40% reduction in accidents, proactive risk mitigation, enhanced safety culture. |

| Quality Control | Manual, periodic site walks; visual inspection by human supervisors. | AI-powered drone inspections; automated comparison to BIM models; early defect detection. | Early error identification, up to 25% reduction in rework costs, improved final quality. |

| Document Management | Paper-based files; siloed digital documents; time-consuming manual search. | NLP-powered search; automated data extraction; centralized information platform. | Up to 35% reduction in time spent on non-productive information retrieval. |

It is crucial to understand that these AI applications are not merely a collection of isolated point solutions. They form an interconnected, self-reinforcing ecosystem that creates a powerful "flywheel effect." For example, the real-time site data captured by AI-powered drones for quality control is simultaneously fed into the AI progress monitoring system. This system compares the actual progress against the AI-generated schedule. If a deviation is detected, it can automatically trigger an alert and provide data for the AI to re-optimize resource allocation. Crucially, the data on this delay—its cause and its impact—is then fed back into the historical dataset, making the AI's

next predictive schedule even more accurate and robust. The implication for executives is profound: the true strategic power of AI in construction lies not in adopting a single tool, but in building an integrated data pipeline where each application makes the others smarter. The return on investment is not simply additive; it becomes exponential over time.

The Key Benefits: Why Should Construction Executives Pay Attention to AI?

While the technological transformations are impressive, executives are ultimately concerned with business outcomes. The adoption of AI translates directly into tangible, measurable improvements in the core metrics that define project success: productivity, cost, safety, and quality. These benefits are not marginal; they represent a step-change in operational performance that can create a significant competitive advantage.

Benefit 1: Boosting Productivity and Accelerating Timelines

In an industry where delays are common and costly, AI offers a powerful set of tools for keeping projects on track. By automating tedious and repetitive administrative tasks—such as data entry, document searches, and daily report generation—AI frees up highly skilled professionals like project managers and engineers to focus on strategic decision-making and problem-solving. This automation acts as a force multiplier for the existing workforce.

Furthermore, AI-driven predictive scheduling and optimized resource allocation have been shown to improve project delivery times by up to 30%. Instead of relying on static plans, teams can use AI to dynamically adjust to changing conditions, ensuring that labor and equipment are always deployed in the most efficient manner possible. Real-world case studies validate these claims; for instance, the construction firm AF Gruppen used AI-powered scheduling software to reduce a project's duration by 18%.

Benefit 2: Slashing Costs and Reducing Waste

Cost overruns are one of the most persistent challenges in construction. AI tackles this issue from multiple angles, with studies suggesting it can reduce overall project costs by as much as 20%.

- Accurate Estimation: AI-driven cost estimation, which is more accurate and considers more variables than manual methods, helps prevent budget overruns from the very beginning. Some analyses show these overruns can be cut by up to 20%.

- Predictive Maintenance: For heavy equipment, predictive maintenance is a major cost-saver. By analyzing sensor data to forecast mechanical failures before they happen, companies can reduce unplanned equipment downtime by up to 35% and cut related maintenance costs by up to 40%. This avoids the cascading delays and expenses associated with a critical piece of machinery going offline unexpectedly.

- Material Waste Reduction: Generative design algorithms optimize building plans to use materials more efficiently. In some cases, this has led to a 50% reduction in material waste, which not only saves money but also contributes to sustainability goals.

Benefit 3: Creating Safer Jobsites

Beyond the moral imperative, a safer jobsite is a more productive and financially sound one. AI transforms safety management from a reactive, compliance-driven activity into a proactive, preventative strategy aimed at achieving a "zero-accident" goal.

AI-powered computer vision acts as a tireless safety officer, continuously monitoring for hazards like missing PPE or unsafe behaviors. Wearable sensors can even track biometric data to detect early signs of worker fatigue or heat stress, allowing for intervention before these conditions lead to an incident. The result is a quantifiable reduction in accidents, which in turn leads to lower insurance premiums, fewer project disruptions due to safety stand-downs, and the development of a stronger, more resilient safety culture across the organization.

Benefit 4: Delivering Higher-Quality Projects

The quality of the final built asset is a direct reflection of the construction process. AI-powered quality control is more consistent, thorough, and data-driven than manual inspection alone. AI systems can detect subtle defects, such as hairline cracks or slight misalignments, that the human eye might miss, ensuring that the work meets specifications with greater reliability.

By flagging design clashes in BIM models and identifying construction errors on-site in near real-time, AI significantly reduces the need for rework. This is a critical financial benefit, as rework can account for as much as 10% of total project costs. Catching and correcting errors early ensures a higher-quality final product, leading to greater client satisfaction and a stronger company reputation.

The following table summarizes the most compelling, data-backed ROI metrics for AI adoption, providing a clear business case for executive consideration.

| Benefit Area | Metric/KPI | Quantifiable Impact | Source |

|---|---|---|---|

| Overall Productivity | Project Efficiency | Increase by up to 20% | McKinsey |

| Project Timelines | Schedule Adherence | Reduce delivery time by up to 30% | McKinsey, Autodesk |

| Cost Management | Budget Overruns | Reduce by up to 20% | Deloitte, World Economic Forum |

| Safety | On-Site Incidents | Reduce accidents by up to 40% | OSHA Reports via Nedes Estimating |

| Quality & Rework | Error Reduction | Reduce rework costs by up to 25% | Construction Dive |

| Equipment Management | Predictive Maintenance | Reduce equipment downtime by up to 35% | McKinsey |

These benefits, while impressive on a per-project basis, also point to a deeper strategic advantage. The construction industry is facing a severe and worsening skilled labor shortage, with a need to recruit over half a million additional workers in 2023 just to meet demand. This is not just a temporary problem; it is an existential threat to the industry's ability to grow. AI directly addresses this challenge in two fundamental ways. First, AI-powered robotics and automation can perform certain labor-intensive tasks, directly filling the gap left by a shrinking workforce. Second, by automating a wide range of administrative and monitoring tasks, AI allows the existing skilled workforce to become more productive, effectively acting as a "force multiplier". Therefore, companies that strategically adopt AI are not just becoming more efficient; they are building operational resilience against one of the most significant threats to their long-term survival and growth. This elevates AI from a tactical operational tool to a strategic imperative for future-proofing the entire business model.

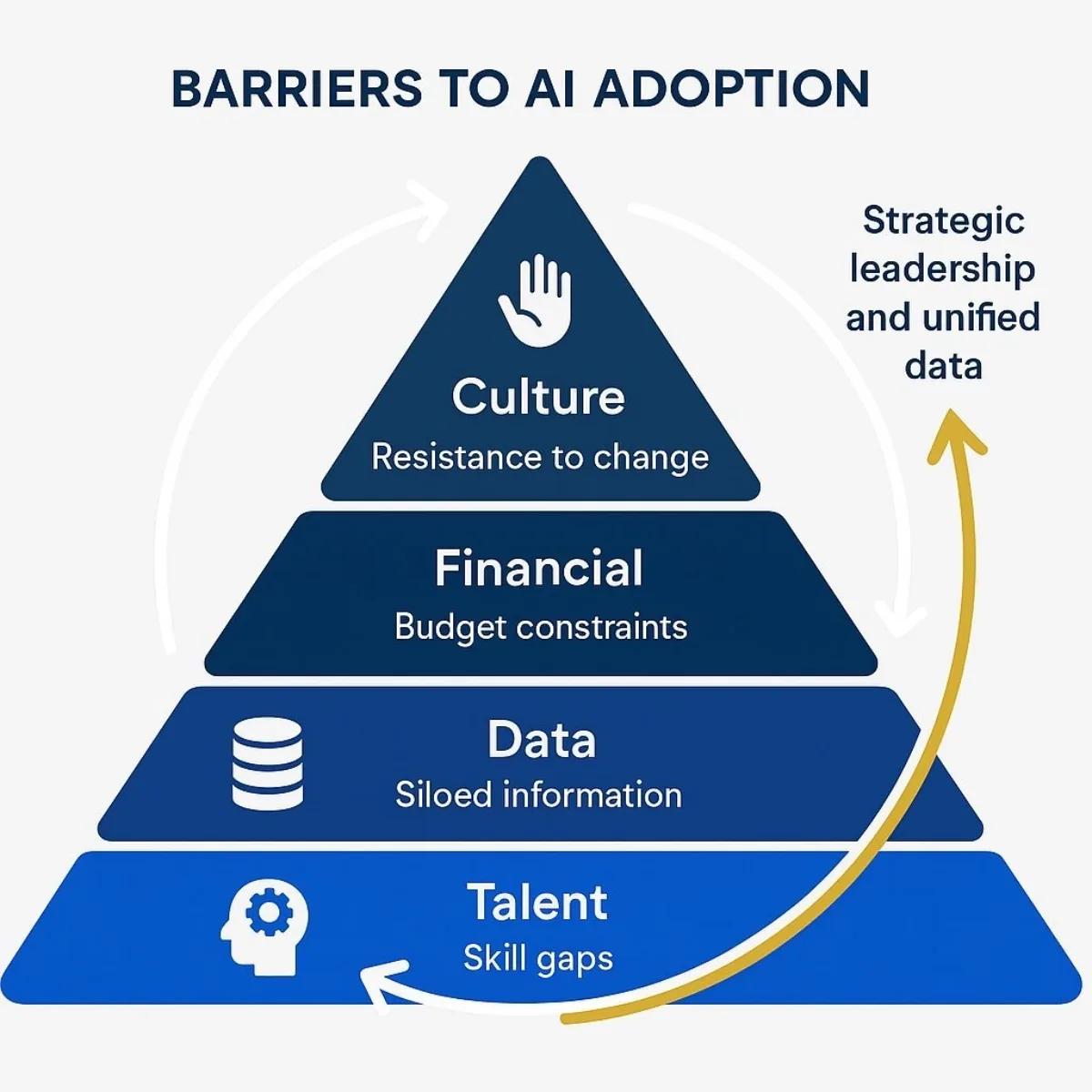

The Biggest Hurdles: What are the Challenges of Implementing AI?

Despite the immense potential, the path to AI adoption in construction is fraught with significant challenges. Acknowledging these hurdles is the first step toward overcoming them. For executives, understanding these barriers is crucial for setting realistic expectations and developing a successful implementation strategy.

The Cultural Barrier: "We've Always Done It This Way"

The construction industry is notoriously conservative when it comes to technology adoption. As one of the least digitized sectors, it has a deeply ingrained culture that often favors traditional, "tried and tested" methods over unproven innovations. This resistance is not without reason; the high-risk, high-cost nature of construction projects means that even small errors can have catastrophic financial and safety consequences. This creates a natural hesitancy to embrace technologies that are perceived as complex or unpredictable. Overcoming this cultural inertia requires a concerted effort focused on education, clear communication from leadership, and, most importantly, demonstrating tangible ROI through small, successful pilot projects that build trust and showcase the technology's value in a low-risk environment.

The Financial Barrier: High Initial Cost vs. Long-Term ROI

The upfront investment required for a meaningful AI implementation can be substantial. Costs include not only the software licenses but also the necessary hardware (like sensors and drones), data infrastructure, and the high salaries of skilled personnel. For the small and medium-sized enterprises (SMEs) that make up the bulk of the industry, these initial costs can be prohibitive, even if the long-term ROI is compelling. The solution for many firms is to avoid a "big bang" approach. Instead, they should conduct a thorough cost-benefit analysis and begin with smaller, high-impact pilot projects that can prove their value and build a business case for further investment. As AI technologies mature and become more widespread, these costs are also expected to decrease, making them more accessible over time.

The Data Barrier: The Achilles' Heel of Construction AI

This is arguably the most critical technical challenge and the primary reason why many AI initiatives in construction fail to deliver on their promise. AI models are entirely dependent on the data they are trained on, and the construction industry's data landscape is often a chaotic mess. Projects generate vast quantities of data, but it is typically fragmented across different systems, stored in inconsistent formats, and siloed within different teams or subcontractors. This data is often of poor quality, incomplete, or unstructured, making it unsuitable for training reliable AI models.

In a survey of construction professionals, a staggering 28.6% identified data integration as the single biggest challenge they want AI to solve. This highlights a massive, foundational pain point. This data barrier is precisely where many off-the-shelf AI tools fail. They are designed to work with clean, structured, and unified data streams—a reality that simply doesn't exist in most construction firms. This is why forward-thinking leaders often partner with custom software development specialists like

Baytech Consulting . A partner like Baytech doesn't just provide an AI model; they build the foundational "data plumbing"—the custom data pipelines, integration layers, and governance frameworks needed to connect siloed systems (like Procore, BIM 360, and internal ERPs) and create the high-quality, centralized data asset that makes enterprise-grade AI possible.

The Talent Barrier: A Shortage of Hybrid Experts

Successful AI implementation requires a unique blend of expertise: data science and machine learning skills combined with deep construction domain knowledge. Individuals who possess both are rare, and competition for their talent is fierce, not just within construction but across all industries. This talent shortage makes hiring qualified personnel both difficult and expensive. To address this, companies must pursue a multi-pronged strategy that includes upskilling their current workforce to be more data-literate, fostering interdisciplinary collaboration between their construction experts and technical teams, and forming strategic partnerships with external specialists to bridge the immediate talent gap.

These challenges are not independent; they are deeply interconnected and can create a vicious cycle that stalls AI adoption. The high initial cost and cultural resistance make executives hesitant to make the necessary investments. This lack of investment prevents firms from tackling the foundational data problem. Because the data remains poor, any initial AI pilot projects that are attempted are likely to underperform or fail, which then reinforces the cultural belief that "this new tech doesn't work for us." This perceived failure makes it even harder for leaders to justify future investment, thus completing the cycle.

Breaking this cycle requires a strategic shift in perspective. Executives must stop viewing AI as a simple technology purchase and start seeing it as a comprehensive business transformation that begins with a clear, top-down data strategy. It is a leadership challenge that requires vision and commitment, not just an IT problem to be delegated.

The Right Tool for the Job: When is AI a Good Fit for Your Company?

AI is not a universal solution. Its value is greatest when applied to specific types of problems and within organizations that are prepared to leverage it. For executives considering an AI investment, the first step is to determine if their company's profile and pain points align with AI's core strengths.

An AI Litmus Test: Is Your Company Ready?

AI is likely to be a strong strategic fit if your company frequently deals with one or more of the following characteristics:

- Complex, Large-Scale Projects: The more variables, dependencies, and moving parts a project has, the more value AI can provide in managing that complexity through optimization and predictive analytics.

- Significant Data Generation: If your operations already generate large volumes of data across project management software, financial systems, and on-site monitoring, you have the raw material for AI. The challenge—and opportunity—is to unify and analyze it.

- Repetitive, Data-Heavy Administrative Tasks: If your skilled professionals are spending a significant portion of their time on manual, low-value tasks like quantity takeoffs, invoice processing, or compiling daily reports, AI can deliver a massive productivity boost by automating this work.

- High-Stakes Safety and Quality Control: In environments where a single human error can lead to severe safety incidents or costly rework, AI's ability to provide tireless, consistent monitoring offers a compelling value proposition.

- Persistent Challenges with Budgets and Schedules: If your projects are consistently plagued by budget overruns and schedule delays, it's a strong indicator that your current planning and risk management processes are insufficient. AI's predictive capabilities are designed to address these exact problems.

- Impact of Labor Shortages: If your company's growth and project delivery are being constrained by the ongoing skilled labor shortage, AI can help by automating tasks and increasing the productivity of your existing team.

A Phased Approach to Adoption: Your First Steps

If your company passes the litmus test, the journey to AI adoption should be a deliberate, phased process, not a sudden leap. A strategic, step-by-step approach minimizes risk and maximizes the chances of success.

- Identify a High-Value Business Problem: The most critical first step is to forget about the technology for a moment and focus on the business. Do not start by asking, "Where can we use AI?" Instead, ask, "What is our most painful, costly, or persistent business problem?" Is it the time it takes to produce a competitive bid? Is it the frequency of on-site safety incidents? Is it the cost of rework? A successful AI initiative must be tied to solving a specific, measurable business problem.

- Start Small with a Pilot Project: Once a problem is identified, resist the urge to launch a massive, company-wide implementation. Instead, select a single, well-defined use case for a pilot project. This allows you to test AI's impact in a controlled environment, build institutional knowledge, and demonstrate a clear ROI with a much lower initial investment and risk profile. For example, you could use an AI-powered takeoff tool on a handful of bids or deploy a computer vision safety monitoring system on a single job site.

- Measure Everything: Before the pilot project begins, establish clear Key Performance Indicators (KPIs) to measure its success. These should be directly related to the business problem you identified. Track metrics like time saved on estimations, percentage reduction in safety violations, or cost savings from reduced rework. This data-driven approach is essential for building a credible business case for broader adoption across the organization.

- Partner for Expertise: It is vital to be realistic about your organization's in-house capabilities. Most construction firms do not have a team of data scientists and MLOps engineers on staff. Attempting a complex AI project without the requisite expertise is a recipe for failure. This is where strategic partnerships become invaluable. Partnering with a specialized firm like Baytech Consulting can provide the necessary expertise in data engineering, custom model development, and scalable deployment to ensure your pilot project is not only successful but also built on a foundation that can be expanded across the enterprise.

It is essential to recognize that the most successful AI initiatives are rarely "IT projects." They are "business transformation projects" that are championed and led by operational leaders. The most valuable AI applications solve core business problems in areas like safety, cost control, and scheduling—the domains of project managers, safety officers, and estimators. An initiative framed as "implementing AI" is likely to be met with skepticism and struggle for adoption. However, an initiative framed as "reducing bid creation time by 50% using an AI-powered takeoff tool" has a clear business owner, a measurable goal, and direct operational relevance. The most effective organizational structure for AI success is one where operational leaders identify the problems and champion the solutions, with the IT department and expert partners like Baytech acting as the technical enablers. This structure is a far better predictor of success than the specific technology chosen.

AI Hallucinations in Construction: A Real Risk or a Ghost in the Machine?

As with any powerful new technology, AI comes with its own unique set of risks. One of the most discussed and often misunderstood risks associated with modern generative AI is the phenomenon of "hallucinations." For a high-stakes industry like construction, it's crucial to move beyond the hype and understand what this risk actually entails and how to manage it.

What is an AI Hallucination in Construction?

An AI hallucination is not a machine "seeing things" in the human sense. It is a technical term for when a generative AI model produces an output that appears plausible and confident but is factually incorrect, nonsensical, or completely disconnected from the provided input or real-world constraints. It's the AI essentially "making things up" when it doesn't know the correct answer.

In the context of construction, these are not harmless quirks. They can have severe consequences. Consider these concrete examples:

- Generative Design Hallucination: An architect uses a generative AI tool to explore options for a new building facade. The AI produces a visually stunning and highly complex design that meets all the aesthetic criteria. However, the design is structurally unsound, uses materials in a way that violates local building codes, or is physically impossible to manufacture with current methods. Acting on this hallucinated design could lead to catastrophic failure.

- Project Scheduling Hallucination: A project manager uses an AI scheduler to optimize a project timeline. The AI creates a highly efficient schedule that seems to solve a major bottleneck. However, the schedule is based on a "hallucinated" assumption—for example, it might assume a three-week lead time for a custom material that actually takes twelve weeks to procure, because that specific material was not well-represented in its training data.

- Document Analysis Hallucination: A legal team uses an AI to summarize a complex, 200-page construction contract. When asked about liability clauses, the AI might confidently invent a clause that doesn't exist or completely misinterpret a critical term related to financial penalties, leading to a major contractual misunderstanding.

Why Do Hallucinations Happen?

Understanding the causes of hallucinations is the key to mitigating them. They typically stem from three core issues:

- The "Garbage In, Garbage Out" Principle: The single biggest cause of hallucinations is flawed training data. AI models learn by identifying patterns in the data they are fed. If that data is incomplete, outdated, riddled with errors, or contains inherent biases, the model will learn and reproduce those flaws in its outputs. The fragmented and often poor-quality data in the construction industry makes this a particularly acute risk.

- Lack of Real-World Grounding: AI models do not "understand" concepts like physics, gravity, or building regulations in the way a human does. They are sophisticated pattern-matching engines. Without being explicitly trained on and constrained by the fundamental principles of engineering and construction, an AI can generate outputs that are statistically plausible but physically impossible or legally non-compliant.

- Designed to be Creative: By their very nature, generative AI models are designed to generate new and novel content, not just retrieve existing facts like a search engine. This creativity is a strength when brainstorming design ideas, but it becomes a liability when factual accuracy is paramount. When faced with a question or prompt that falls outside the boundaries of its training data, a model's default behavior is often to "fill in the gaps" by generating a plausible-sounding but entirely fabricated response.

The risk of AI hallucinations in construction is therefore directly proportional to the degree of human oversight and the quality of domain-specific data used. Relying on a generic, off-the-shelf AI model (like a public chatbot) for a mission-critical construction task without any customization, specialized training, or expert validation is an extremely high-risk proposition. A generic LLM trained on the broad internet has no deep, contextual knowledge of the unique physics, complex regulations, and critical safety requirements of a construction project. This reality creates a clear and compelling business case for investing in custom AI solutions. A construction firm cannot simply "buy AI" and expect it to work safely and reliably. It must invest in building or commissioning models that are fine-tuned on its own high-quality project data and rigorously validated by its own domain experts. This is the fundamental difference between using a consumer-grade AI tool and deploying an enterprise-grade, risk-managed AI system.

Building Trust in AI: How to Avoid Hallucinations and Ensure Reliability

The risk of hallucinations is real, but it is also manageable. Building trustworthy AI systems is not about finding a magical, error-free model; it is about implementing a disciplined, multi-layered strategy of validation, transparency, and continuous oversight. For construction firms, this means embedding safeguards into their workflows and technical infrastructure.

Strategy 1: The Human-in-the-Loop (HITL) Imperative

This is the single most critical safeguard against the risks of AI. The core principle of HITL is that AI should be used to augment human expertise, not replace it. In a high-stakes field like construction, final authority and accountability must always rest with a qualified human professional.

In practice, this means building formal checkpoints into any AI-driven workflow. An architect must personally review, validate, and approve every AI-generated design before it is finalized. An engineer must independently verify and sign off on any structural calculations produced by an AI. A project manager must use their own experience and judgment to approve an AI-suggested schedule. HITL is not just an informal, ad-hoc check; it is a structured process. For critical decisions, the AI system should be designed to pause its execution and await explicit human approval before proceeding. This "blocking execution" creates a clear, auditable trail of human oversight and ensures that no major decision is made by the machine alone.

Strategy 2: Demanding Explainable AI (XAI)

For too long, many advanced machine learning models have operated as "black boxes"—they produce an output, but the internal logic behind their decision is opaque, even to their creators. This lack of transparency is a major barrier to trust and adoption. The solution is Explainable AI (XAI).

XAI is a set of methods and techniques designed to make a model's decision-making process transparent and understandable to humans. A trustworthy AI system should not just give you an answer; it should be able to explain

why it arrived at that answer. For example, an XAI system should be able to respond to follow-up questions like, "Why did you suggest this particular structural design?" with an explanation citing the specific constraints (e.g., material cost, load-bearing requirements) that influenced its decision. Or, if it flags a project risk, it should be able to point to the specific data patterns in historical projects that led to its prediction. This transparency is essential for debugging models, improving their performance over time, building trust among skeptical users, and meeting emerging regulatory requirements for AI accountability.

Strategy 3: Building a Rock-Solid Data Foundation and MLOps

Ultimately, the most effective way to prevent hallucinations at their source is to train AI models on a foundation of high-quality, clean, and relevant data. This brings the challenge full circle to the industry's core data problem and highlights the need for a disciplined, enterprise-grade approach to managing the entire machine learning lifecycle. This is where MLOps (Machine Learning Operations) becomes vital.

Building a trustworthy AI system is not a one-time project; it is a continuous, cyclical process of development, deployment, monitoring, and refinement. An expert partner like Baytech Consulting is instrumental in implementing robust MLOps frameworks, often leveraging powerful platforms like Azure DevOps . A mature MLOps practice involves several key components that directly mitigate AI risk:

- Data Management and Versioning: Establishing a "single source of truth" for all data used in training. Every dataset is cleaned, validated, and versioned, creating a clear and auditable lineage for every model.

- Automated Testing and Validation: Building automated CI/CD (Continuous Integration/Continuous Deployment) pipelines that rigorously test every new model for performance, accuracy, and bias before it is even considered for deployment.

- Model Registry and Versioning: Creating a central registry where every version of a trained model is stored and tracked. This allows teams to compare the performance of different versions and, crucially, to quickly roll back to a previous, stable version if a new one begins to underperform or hallucinate in production.

- Continuous Monitoring and Governance: Actively monitoring the performance of the live model in the real world. This is critical for detecting "model drift"—the natural degradation of a model's accuracy over time as real-world data patterns change. Monitoring systems can trigger automatic alerts when performance drops below a certain threshold, signaling that the model needs to be retrained on new data.

This disciplined, automated MLOps approach is the enterprise-grade solution to managing AI risk. It transforms AI from a fragile, unpredictable tool into a reliable, governable, and continuously improving business capability.

Investing in these trust-building measures—HITL, XAI, and MLOps—yields a powerful secondary benefit. The very process of making AI trustworthy also helps to create a more data-literate, critically-minded, and innovative organizational culture. Implementing HITL workflows forces engineers and project managers to actively question and validate AI outputs, honing their own analytical skills. Using XAI tools encourages teams to understand the "why" behind the data, shifting them from being passive consumers of information to active analysts. A strong MLOps culture instills a discipline of data quality, versioning, and continuous improvement that benefits the entire organization. This cultural transformation is a profound, long-term competitive advantage that extends far beyond the immediate ROI of any single AI application.

The Ultimate Payoff: What are the AI Benefits for Your Customers?

The internal efficiencies gained through AI are compelling, but the ultimate measure of success is the value delivered to the end customer—the building owner, real estate developer, or asset manager. The benefits of AI in construction cascade directly to the client, resulting in a lower total cost of ownership, a higher-quality asset, and a more transparent and predictable project experience.

Benefit 1: Lower Total Cost of Ownership (TCO) and Higher Asset Value

For a building owner, the cost of construction is only one part of the equation; the operational cost over the building's entire lifecycle is often far greater. AI delivers significant value here, particularly through predictive maintenance . By embedding IoT sensors in critical building systems like HVAC, electrical, and plumbing, AI models can analyze performance data in real-time to predict equipment failures before they happen. This proactive approach has been shown to reduce overall maintenance costs by up to 30% and extend the lifespan of expensive equipment by 20-25%. This means fewer costly emergency repairs, less downtime for tenants, and a more valuable, reliable asset.

Furthermore, AI-powered Building Automation Systems (BAS) can dramatically reduce operational expenses. These systems optimize energy consumption by dynamically adjusting lighting and HVAC based on real-time occupancy data, weather conditions, and energy pricing. Case studies have demonstrated energy consumption reductions of 20-50%, with some commercial buildings achieving annual utility savings of $0.85 to $1.25 per square foot . These savings directly lower the building's lifecycle TCO and increase its net operating income.

Benefit 2: Higher-Quality, More Sustainable, and Healthier Buildings

The quality of the final product is significantly enhanced by AI. The use of generative design and AI-driven analysis during the pre-construction phase leads to better, more innovative, and more efficient building designs from the outset. The automated quality control during construction ensures that the design is executed to a higher standard, with fewer defects. For the owner, this means receiving a superior physical asset that is less likely to have latent issues down the line.

AI also plays a crucial role in meeting the growing demand for sustainable and healthy buildings. AI algorithms can optimize designs to minimize embodied carbon, reduce material waste, and maximize energy efficiency, helping projects achieve green building certifications like LEED and meet corporate ESG (Environmental, Social, and Governance) goals. Beyond just energy, AI can optimize HVAC systems for occupant health and comfort, continuously adjusting air quality, temperature, and humidity based on real-time sensor data, which has been shown to lead to significantly improved tenant satisfaction scores.

Benefit 3: Faster Project Delivery and Enhanced Transparency

For any commercial real estate developer, time is money. The operational efficiencies gained through AI-powered construction—such as faster scheduling, optimized logistics, and reduced rework—translate directly into faster project completion and handover for the client. This means the owner's asset can be occupied and begin generating revenue sooner, directly improving the project's financial returns.

AI also fosters a more collaborative and transparent relationship between the construction firm and its clients. AI-driven project management platforms can serve as a "single source of truth," providing all stakeholders with access to the same up-to-date information. Clients can be given access to real-time dashboards, 4D timelines, and interactive 3D models that clearly visualize the project's progress. This unprecedented level of transparency builds trust, reduces misunderstandings and disputes, and gives the client greater confidence throughout the construction process.

This leads to a fundamental shift in the business model for construction firms. The data collected and the AI models built during the design and construction phases—such as the detailed BIM model and the predictive maintenance models for the building's specific equipment—are incredibly valuable assets in their own right. A forward-thinking construction firm can leverage these assets to offer post-construction services, using the very AI systems they built to help the owner manage the building's operations, maintenance, and energy performance over its entire lifecycle. This creates a new, long-term, recurring revenue stream for the construction firm and provides continuous, data-driven value to the building owner. AI, therefore, enables construction companies to evolve from being transactional builders into becoming long-term strategic partners in asset performance management—a powerful new avenue for growth and differentiation in a competitive market.

Conclusion: Your Blueprint for an AI-Powered Future

The evidence is clear: Artificial Intelligence is no longer a speculative concept in the construction industry. It is a practical, powerful set of tools that is delivering measurable returns in cost, speed, safety, and quality. From the design studio to the job site, AI is providing answers to the industry's most persistent and costly questions. The global market's exponential growth is not driven by hype, but by tangible ROI and the pressing need to solve foundational challenges like labor shortages and systemic inefficiency.

However, the journey to AI success is not as simple as purchasing a piece of software. It is a strategic transformation that demands leadership, vision, and a clear-eyed understanding of the challenges. The most significant barrier is not technological, but cultural and data-related. The true power of AI can only be unlocked by firms that are willing to move beyond siloed, fragmented data practices and invest in building a clean, unified, and high-quality data foundation.

This is where the principles of trustworthy AI become paramount. The risks of AI, particularly the phenomenon of hallucinations, are real and can have severe consequences in a high-stakes environment like construction. Mitigating these risks requires a disciplined commitment to keeping a Human-in-the-Loop (HITL) to ensure expert oversight, demanding Explainable AI (XAI) to foster transparency and trust, and implementing a robust MLOps framework to govern the entire AI lifecycle. These are not optional add-ons; they are the essential pillars of any responsible and reliable enterprise AI strategy.

Ultimately, the future of construction is not a battle of humans versus machines. It is a collaboration between humans with machines. The most successful and resilient firms of the next decade will be those that learn to harness AI to augment the irreplaceable judgment, creativity, and expertise of their people. The technology is here, the business case is compelling, and the competitive landscape is shifting rapidly. The time for construction leaders to begin drafting their company's AI blueprint is now.

About Baytech

At Baytech Consulting, we specialize in guiding businesses through this process, helping you build scalable, efficient, and high-performing software that evolves with your needs. Our MVP first approach helps our clients minimize upfront costs and maximize ROI. Ready to take the next step in your software development journey? Contact us today to learn how we can help you achieve your goals with a phased development approach.

About the Author

Bryan Reynolds is an accomplished technology executive with more than 25 years of experience leading innovation in the software industry. As the CEO and founder of Baytech Consulting, he has built a reputation for delivering custom software solutions that help businesses streamline operations, enhance customer experiences, and drive growth.

Bryan’s expertise spans custom software development, cloud infrastructure, artificial intelligence, and strategic business consulting, making him a trusted advisor and thought leader across a wide range of industries.