How Custom Document Management Systems Transform Energy Operations

August 20, 2025 / Bryan ReynoldsBeyond the Filing Cabinet: How Custom Software Solves Document Chaos and Unlocks Operational Excellence in the Energy Sector

Introduction: The Billion-Dollar Drag of Paper in a Digital-First World

In an industry defined by precision engineering, high-stakes capital projects, and complex global logistics, a surprising vulnerability persists at the core of many energy operations: paper. While companies invest billions in advanced drilling technology and sophisticated grid management, mission-critical information—field tickets, operational logs, safety checklists, and compliance records—often remains trapped in physical binders, disconnected spreadsheets, and overflowing filing cabinets. This reliance on analog-era processes is more than an administrative headache; it is a significant, quantifiable drain on resources and a direct threat to operational integrity.

The scale of this inefficiency is staggering. Across industries, studies show that information workers spend an average of 4.5 hours per week simply searching for documents, a loss of productivity that translates to an annual cost of nearly $20,000 per employee. In the complex, geographically dispersed environment of the energy sector, where teams are split between remote field sites and corporate offices, this cost is undoubtedly magnified. The sheer volume of paperwork, encompassing everything from environmental impact assessments and engineering schematics to regulatory permits and safety protocols, can overwhelm even the most organized companies, leading to operational paralysis.

This begs a critical question for any executive: In a sector where a single miscalculation can have catastrophic consequences, why is the lifeblood of the operation—its data—still managed with such inefficiency and risk? The answer often lies not in a lack of technological solutions, but in a powerful organizational inertia. The mindset of "this is how we've always done it" persists because the complexity of energy operations makes any fundamental change seem daunting. This inertia, however, creates a hidden risk premium on every aspect of the business. It tacitly accepts the potential for human error, project delays, and regulatory non-compliance as an unavoidable cost of doing business. This report challenges that assumption, providing the strategic framework and data-driven analysis to demonstrate that modernizing document management is not just an IT upgrade, but a core strategic imperative for achieving operational excellence, mitigating systemic risk, and securing a competitive advantage in a digital-first world.

Section 1: What Are the True Costs of Inefficient Document Management?

The reliance on paper and fragmented digital files imposes a multifaceted burden on energy companies. These costs extend far beyond the price of printer ink and storage boxes, permeating every level of the organization to create financial leakage, heighten legal exposure, and introduce dangerous operational risks. Understanding the full scope of these costs is the first step toward building a compelling business case for change.

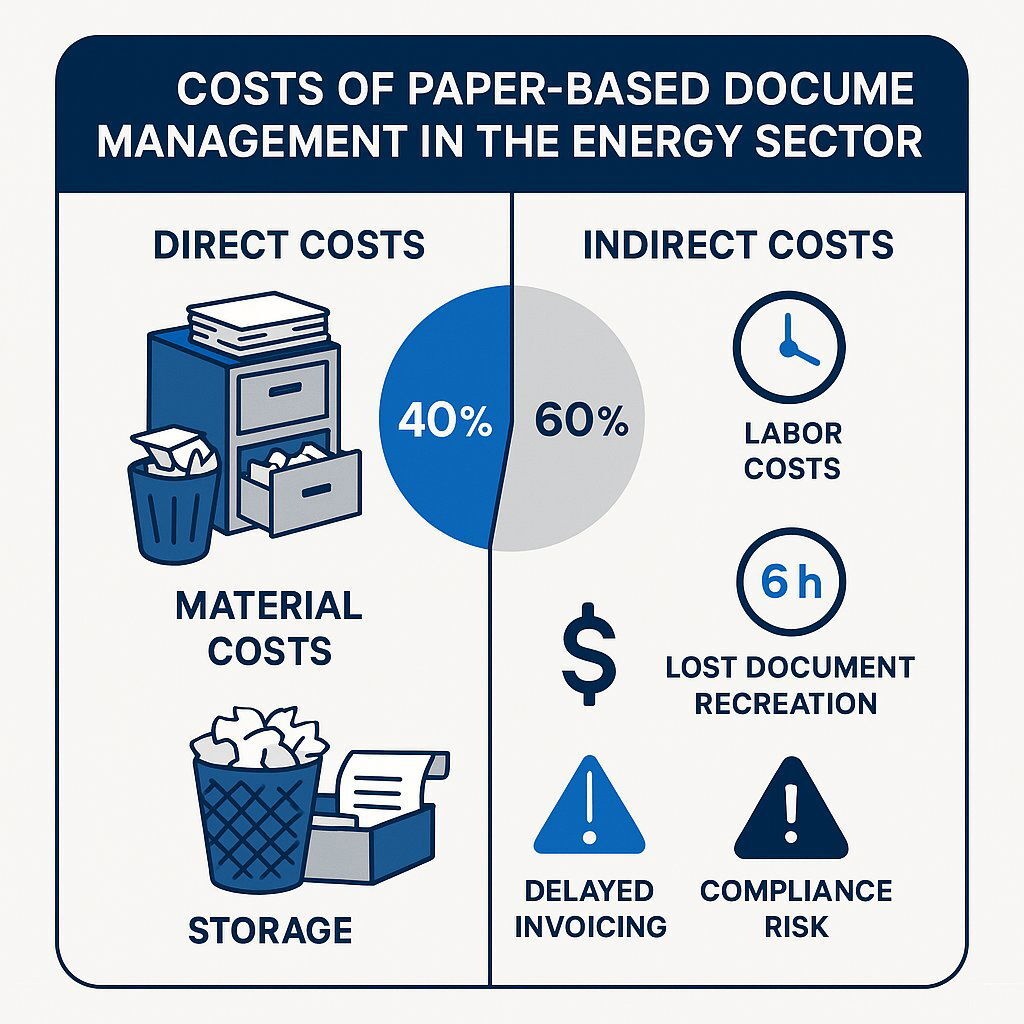

The Financial Bleed: Direct and Indirect Costs

The most visible costs are the direct expenses associated with managing a paper-based ecosystem. These include the procurement of paper, toner, printers, and photocopiers, as well as the significant cost of physical storage space, which often necessitates renting expensive off-site facilities as internal rooms overflow. Compounding these material costs is the immense labor expenditure. Research indicates that it takes an average of 18 minutes for an employee to locate a single paper document, a shocking inefficiency when multiplied across an entire workforce. Furthermore, with over 7.5% of all paper documents getting lost and another 3% being misfiled, countless hours are wasted not just searching, but recreating lost work. This constant, low-level drain on productivity directly inflates operational overhead and diverts skilled personnel from value-adding activities to administrative drudgery.

However, these direct costs are often dwarfed by the indirect financial impacts. In the energy sector, operational timelines are inextricably linked to revenue. Paper-based field tickets and work orders create a significant lag in the financial cycle. A handwritten ticket from a remote rig must be physically transported to an office, manually entered into a system, reviewed, and approved before an invoice can even be generated. This inherent delay slows revenue recognition and negatively impacts cash flow, a critical metric for any capital-intensive business. Moreover, when miscommunication arises between field and office teams due to illegible handwriting or lost paperwork, it frequently leads to costly mistakes and rework. One utility reported that implementing a digital system helped prevent multiple change orders with its large contract partners, highlighting the direct link between poor documentation and project cost overruns.

The High-Stakes World of Compliance and Legal Risk

The energy industry operates within one of the most stringent regulatory environments in the world. Agencies and standards like the Occupational Safety and Health Administration (OSHA), the Environmental Protection Agency (EPA), the Sarbanes-Oxley Act (SOX), and the Resource Conservation and Recovery Act (RCRA) mandate meticulous, auditable, and secure record-keeping. Navigating this regulatory maze with a paper-based system is fraught with peril.

The consequences of failure are severe. Under the EPA's RCRA, for example, improper disposal of electronic waste can result in penalties of up to $50,000 per violation day and five years in prison, with penalties doubling for a second offense. Similarly, failing to produce the necessary financial records during a SOX audit or safety documents during an OSHA inspection can lead to crippling fines and legal action. Paper documents are inherently difficult to secure, track, and manage according to specific retention schedules—some environmental reports must be kept indefinitely, while financial records often require a 7-year retention period. A lost or improperly accessed file doesn't just represent an inefficiency; it can directly threaten a company's legal standing and license to operate. The fact that an estimated 21% of all productivity losses are linked to document security concerns underscores the deep connection between operational inefficiency and unmanaged risk.

The Operational Quagmire: Safety, Version Control, and Data Silos

Beyond the financial and legal ramifications, inefficient document management corrodes the very foundation of safe and effective operations. One of the most critical dangers is the problem of version control. In an environment where teams collaborate on complex engineering drawings, safety protocols, and operational procedures, ensuring that every individual is working from the most current version is paramount. A real-world example from Hoosier Energy starkly illustrates this risk: when two engineers inadvertently worked on different versions of the same file, data was overwritten and critical information was lost. A senior engineer noted that the potential consequences were dire, ranging from power blackouts to, in the worst-case scenario, a serious safety incident where "someone actually getting hurt." This demonstrates that version control is not an abstract IT concept but a frontline safety issue.

This problem is exacerbated by the data silos created by paper-based systems. When critical information is locked away in physical documents scattered across different locations, managers have no real-time visibility into operations. It becomes nearly impossible to generate accurate, timely reports on workforce productivity, equipment health, or emerging safety trends. Field crews may be dispatched with outdated work orders or schematics because the updated versions are stuck in a manual approval process, leading to wasted time, incorrect work, and potentially hazardous situations. Finally, the physical vulnerability of paper poses a constant threat. A single incident, such as a fire, flood, or even simple misplacement, can lead to the irreversible loss of invaluable intellectual property, including engineering data, geological surveys, and operational histories.

This analysis reveals that poor document management is not a series of isolated problems but a systemic risk multiplier. The different categories of risk—financial, legal, and operational—are not siloed; they are deeply interconnected. A single error originating from a document management failure can cascade across the entire organization. For instance, an outdated engineering drawing represents a version control failure. If used in the field, it can lead to a safety incident (an operational and human risk), which in turn triggers a regulatory investigation and potential fines (a legal risk), and necessitates costly rework and project delays (a financial risk). In this context, inefficient documentation acts as the common, underlying vulnerability that amplifies all other business risks. Therefore, solving this problem is not merely an exercise in incremental cost-saving; it is a core strategic initiative to build a more resilient, secure, and profitable enterprise.

Section 2: How Does a Modern Document Management System (DMS) Create Value?

Transitioning from the persistent problems of paper-based systems, the solution lies in a comprehensive digital approach. A modern Document Management System (DMS) is far more than a digital filing cabinet; it is a strategic platform designed to centralize, automate, and secure the flow of information. By directly addressing the pain points of cost, risk, and inefficiency, a DMS creates tangible value across the enterprise.

The Foundation: A Centralized, Secure "Single Source of Truth"

The foundational principle of a DMS is the elimination of data silos. It achieves this by creating a single, centralized repository where all business-critical documents—from engineering drawings and well logs to contracts and HR files—are stored, managed, and controlled. This single source of truth provides immediate and profound benefits. First, it enables instant accessibility. Authorized personnel, whether in a downtown office or at a remote drilling site, can access the exact information they need from any device with an internet connection, breaking down the communication barriers that have long plagued the energy industry.

Second, this centralized system offers a level of security that physical documents can never match. Filing cabinets are vulnerable to theft, unauthorized access, and physical damage. A modern DMS, by contrast, employs robust security protocols, including data encryption both at rest and in transit, granular role-based access controls, and multi-factor authentication. This ensures that sensitive intellectual property and confidential data are protected from both internal and external threats. Finally, cloud-based DMS platforms provide automated backup and disaster recovery capabilities. This simple feature completely mitigates the risk of catastrophic data loss from physical events like fires, floods, or natural disasters, ensuring business continuity and preserving an organization's invaluable historical records.

The Engine: Automating Workflows and Eliminating Manual Drudgery

Where a DMS truly begins to generate transformative value is in its ability to automate workflows. Instead of being static files, documents become active components in a digital process, automating the repetitive, time-consuming, and error-prone tasks that bog down operations. The applications within the energy sector are extensive and impactful.

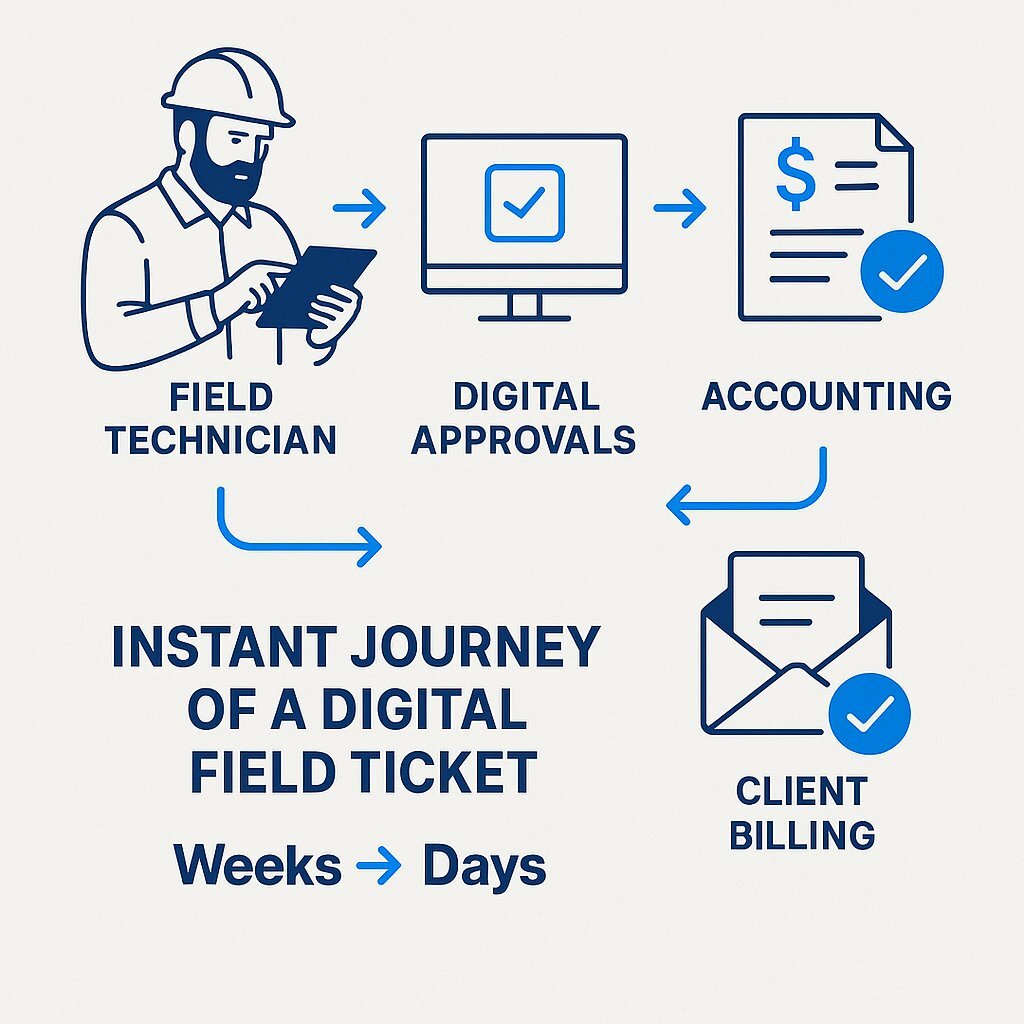

Consider the lifecycle of a field ticket. In a traditional system, a field worker fills out a paper form, which is then physically transported, manually entered, and passed around for approvals. With a DMS, the worker uses a mobile device to fill out a digital form. The moment it is submitted, it can automatically trigger a workflow: the supervisor is notified for approval, the data is sent to the accounting system to generate an invoice, and the client is billed. This single automated process can slash the invoicing and payment cycle from weeks to days, directly accelerating cash flow. A compelling case study from Cabot Oil & Gas shows how they used online forms to move work tickets directly into their accounting system, where they were automatically matched with vendor invoices, revolutionizing their accounts payable process.

This same principle applies to compliance and engineering. A DMS can be configured to automatically enforce document retention and disposal schedules based on specific regulations like SOX or RCRA. It creates a complete, unalterable audit trail for every document, logging every view, edit, and approval. When an auditor calls, preparing the required documentation becomes a simple matter of running a report, a process that takes minutes instead of the days or weeks of manual searching and copying. For engineering teams, automated workflows ensure that any change to a critical schematic or safety procedure is automatically routed to all necessary stakeholders for review and sign-off, guaranteeing that no one is ever working from an outdated and potentially dangerous version.

The Intelligence Layer: Advanced Search, Analytics, and AI

The final layer of value comes from turning stored data into actionable intelligence. Finding a specific piece of information in a paper-based system is a monumental task. A modern DMS, however, offers powerful search capabilities that can locate the needle in any haystack. It uses Optical Character Recognition (OCR) technology to convert the text within scanned paper documents into a fully searchable format. This, combined with advanced indexing using metadata tags—such as project name, equipment ID, well number, or geological formation—allows users to retrieve precise information in seconds. The productivity gains from this capability alone are estimated to be between 20-30%.

Beyond simple retrieval, the centralization of data opens the door to powerful analytics. For the first time, companies can analyze vast stores of previously inaccessible information from operational logs, maintenance records, and safety reports. When integrated with Artificial Intelligence (AI) and Machine Learning (ML), this data can be used to uncover hidden trends, such as identifying the root causes of safety incidents, predicting equipment failures before they happen, or optimizing production schedules. Platforms like Microsoft's Azure Data Manager for Energy are at the forefront of this evolution, providing a cloud-based service specifically designed to unify operational data and apply AI/ML for predictive maintenance and workflow optimization. This signals a fundamental shift in the role of a DMS, from a simple storage system to an intelligent data platform that drives strategic decision-making.

This evolution reveals a crucial distinction: a DMS is not merely a system of record, but a system of engagement. The traditional view of a DMS is that of a digital archive—a passive place to store files. This is its function as a system of record. However, its true value is realized when it becomes an active hub for daily work. Features like mobile access for field crews, real-time collaboration tools, and automated workflows transform the platform into a system of engagement. A field technician is no longer just filing a report at the end of the day; they are initiating a company-wide workflow from their tablet. Engineers are not just retrieving a drawing; they are collaborating on it simultaneously with colleagues across the globe. For an executive, this means the investment is not just in back-office efficiency or data storage. It is a direct investment in front-line productivity, enhanced collaboration, and the agility of the entire workforce. It fundamentally changes how work gets done, not just where it is stored.

Section 3: The Strategic Crossroads: Choosing Between Off-the-Shelf and Custom Software

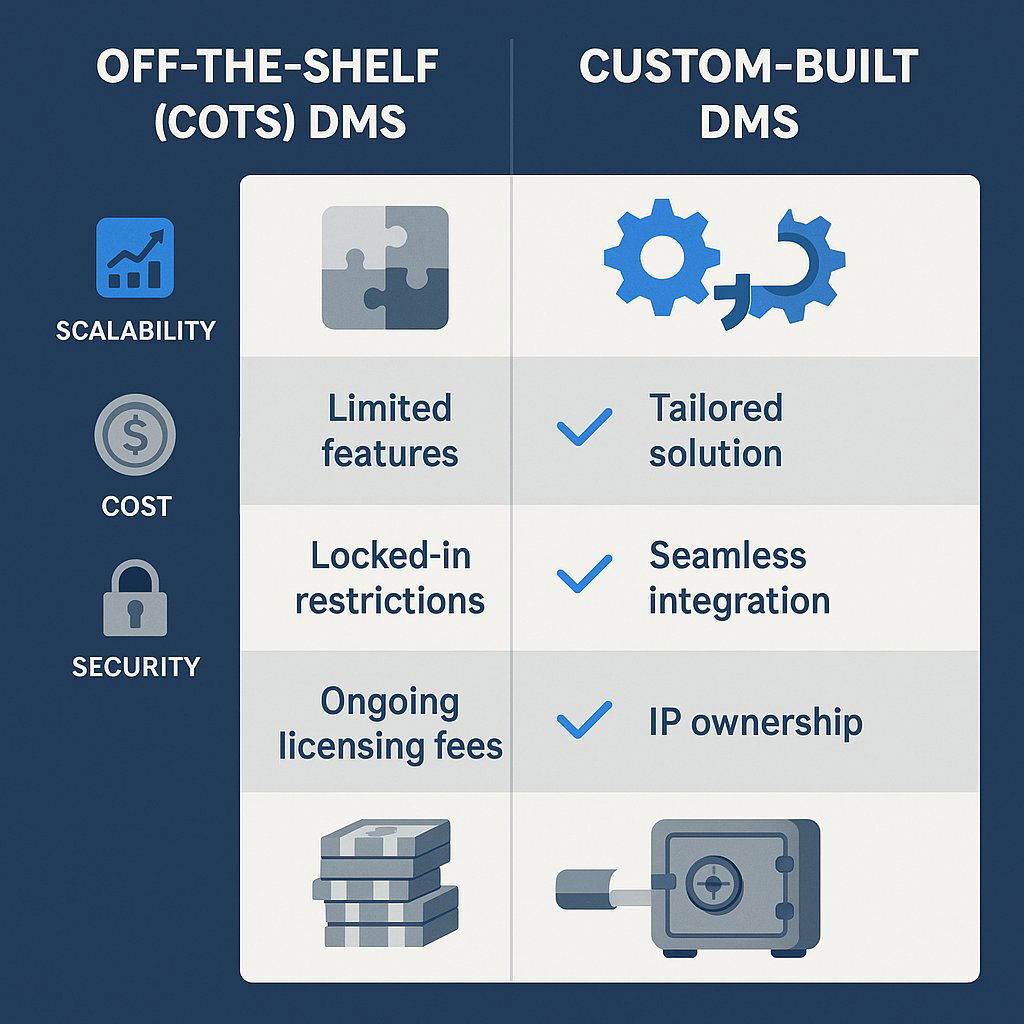

Once an organization recognizes the imperative to modernize its document management, it faces a critical decision: adopt a pre-built, off-the-shelf (COTS) solution or invest in a custom-developed platform. This choice is not merely a procurement exercise; it is a strategic decision that will profoundly impact the company's operational efficiency, long-term costs, and competitive standing. For the highly specialized energy sector, understanding the nuanced trade-offs is essential.

The Lure of Off-the-Shelf (COTS) Software

Commercial off-the-shelf software presents an attractive proposition on the surface. These solutions are ready-made, promising quick deployment and a lower initial cost, which is particularly appealing for organizations with standardized processes or immediate needs under tight budgets. They are often well-tested and come with established community support, offering a sense of reliability.

However, for the energy industry, this "one-size-fits-all" approach frequently proves to be a poor fit. The workflows in upstream, midstream, and downstream operations are unique and highly specialized, involving documents like well permits, drilling logs, pipeline inspection reports, and complex environmental compliance filings that have no equivalent in other industries. COTS systems, with their fixed and generic feature sets, often force companies to abandon their optimized, battle-tested processes and contort their workflows to fit the rigid structure of the software.

This mismatch leads to significant hidden costs and inefficiencies. The software may be bloated with features irrelevant to the energy sector, cluttering the user interface, or, more critically, it may lack essential functionality. This forces employees to develop manual workarounds, revert to spreadsheets, or use multiple disconnected systems to bridge the gaps, defeating the purpose of a unified platform. Furthermore, integrating a generic COTS product with existing, mission-critical enterprise systems—such as Enterprise Resource Planning (ERP), Geographic Information Systems (GIS), or Computerized Maintenance Management Systems (CMMS)—can be exceedingly complex, expensive, and sometimes impossible, resulting in the creation of yet another data silo.

The Competitive Edge of Tailored Technology

In contrast, custom software is engineered from the ground up to be a perfect reflection of a company's specific operational DNA. It is designed to automate and enhance a company's exact workflows, data structures, and strategic objectives, rather than forcing adaptation. This approach, which can be described as

Tailored Tech, offers several profound advantages for an energy company.

First and foremost is the perfect fit. A custom system is built to handle the unique nature of energy-sector documents and processes natively. This ensures that the digital workflow for submitting a drilling log or managing a complex land-lease agreement is intuitive and efficient because it was designed for that specific purpose. Second is seamless integration. Because it is developed with the company's existing technology stack in mind, a custom solution can be architected to connect perfectly with ERP, GIS, and other legacy systems, breaking down data silos and creating a truly unified operational dashboard.

This leads to the third and most strategic advantage: competitive differentiation. An energy company's unique processes and operational knowledge are often a key source of its competitive edge. A custom DMS embeds, automates, and enhances that proprietary knowledge, creating an operational asset that competitors using generic software cannot replicate. Finally, security can be designed to meet the specific and stringent risk and compliance requirements of the energy industry, providing a level of protection that goes far beyond the generalized security of a mass-market product.

The Real TCO: A Long-Term Financial Analysis

A simple comparison of upfront costs is misleading. The correct financial lens for this decision is Total Cost of Ownership (TCO), which accounts for all direct and indirect costs over the entire lifecycle of the product.

The TCO of a COTS solution begins with a low initial price but quickly accumulates additional expenses. These include perpetual subscription or licensing fees that often increase as more users are added or advanced features are required. More significant are the hidden costs: the lost productivity from inefficient workflows, the expense of developing and maintaining manual workarounds, the cost of failed or incomplete integrations, and the potential future cost of migrating to a new platform when the business inevitably outgrows the COTS system's limitations.

The TCO of a custom solution involves a higher upfront development investment, followed by lower, more predictable maintenance costs. Crucially, it is designed to eliminate the hidden costs associated with inefficiency, workarounds, and poor integration. By perfectly aligning with business processes, it maximizes productivity and generates a much stronger long-term return on investment. A final, critical component of TCO is ownership. With custom software, the company owns the intellectual property. It has complete control over the software's future, free from a vendor's unilateral price hikes, feature changes, or the risk of the vendor going out of business. This control is a significant financial and strategic asset that is often overlooked in initial cost comparisons.

The following table provides a clear, comparative framework to aid executives in this strategic decision.

| Criterion | Off-the-Shelf (COTS) DMS | Custom-Built DMS (Tailored Tech) |

|---|---|---|

| Initial Cost | Low upfront investment; often subscription-based. | Higher upfront investment for development. |

| Total Cost of Ownership (TCO) | Can be high over time due to recurring fees, hidden costs of workarounds, and expensive customization. | Lower long-term TCO. One-time investment pays off through greater efficiency and no licensing fees. |

| Workflow Fit | Generic, "one-size-fits-all." Forces the business to adapt its processes to the software. | Tailored. Designed to perfectly match and optimize your unique, industry-specific workflows. |

| Integration | Can be complex and costly. Often creates new data silos if integration with legacy systems fails. | Seamless. Built to integrate with your existing ERP, GIS, CMMS, and other critical systems from day one. |

| Scalability | Limited. May become restrictive as business needs evolve or grow in complexity. | Infinite. Designed to scale and evolve with your business, adapting to new requirements and growth. |

| Security | Generic security protocols managed by the vendor. Less control over specific compliance needs. | Enhanced. Security architecture designed around your specific data sensitivity and regulatory requirements. |

| Competitive Advantage | None. You are using the same tool as your competitors. | Significant. Creates a proprietary operational asset that enhances your unique processes and cannot be replicated. |

| Ownership & Control | You are renting the software. Subject to vendor pricing, updates, and potential discontinuation. | Full Ownership. You own the intellectual property and control the software's destiny. |

Section 4: A Blueprint for Successful Implementation

Embarking on a digital transformation project can feel daunting, particularly in an industry where large-scale IT initiatives have a reputation for complexity and delays. However, a successful DMS implementation is achievable with a structured, pragmatic approach. This blueprint breaks the process down into foundational steps and introduces an agile methodology designed to mitigate risk, ensure user adoption, and deliver value rapidly.

The Foundational Steps: A Phased Approach

A successful implementation follows a logical, phased progression that moves from high-level strategy to granular execution.

- Step 1: Assess and Plan. The project must begin with a comprehensive assessment of the current state. This involves assembling a cross-functional team with representatives from operations, IT, legal, finance, and, most importantly, the field personnel who will be the primary users. This team's first task is to conduct a thorough audit of existing document workflows, identifying all document types (e.g., permits, logs, schematics, contracts), their lifecycle, and the associated pain points. Based on this audit, the team must define clear, measurable business objectives, such as reducing the invoice approval cycle by 50% or cutting audit preparation time by 90%. This phase also includes defining access roles and document retention policies according to regulatory and business needs.

- Step 2: Design and Configure. With a clear plan in place, the next step is to architect the system. This is not just about technology but about translating business logic into a functional structure. Key activities include defining the hierarchical folder structure, establishing the metadata schemas that will make documents easily searchable, and configuring user roles and access control permissions to ensure security. This is also the stage where the automated workflows identified in the planning phase are designed and built, mapping out every step of a process like an engineering change request or a new vendor onboarding.

- Step 3: Migrate and Validate. Moving decades of existing data into a new system is a critical and delicate process. A phased migration strategy is essential, starting with the most active and critical documents to deliver immediate value. Before migration, existing data must be cleaned, organized, and securely backed up. As data is moved into the new DMS, it must be rigorously validated to ensure that all information is accurate, complete, and correctly indexed.

- Step 4: Train and Support. Technology is useless if people do not know how to use it. Comprehensive, role-based training is non-negotiable for successful adoption. Training should be practical and focused on how the new system makes an employee's specific job easier. A best practice is to integrate the training system with the DMS itself, so that when a key document like a safety procedure is updated, it automatically triggers a mandatory training requirement for all affected personnel, with completion tracked in their records. Following the "go-live," providing robust, accessible, and ongoing user support is crucial for overcoming initial hurdles and reinforcing new habits.

The Agile Advantage: Mitigating Risk with Rapid, Iterative Deployment

One of the greatest fears for executives is the "big bang" IT project—a monolithic, multi-year endeavor that consumes vast resources only to fail upon delivery because it is disconnected from user needs. Research from McKinsey and others shows that a significant number of digital transformations in the energy sector stall in "pilot purgatory" for this very reason; they are too slow, too rigid, and fail to generate momentum.

The antidote to this is a modern, agile approach. A Rapid Agile Deployment model abandons the all-or-nothing project in favor of delivering the software in small, manageable, and functional increments. Instead of waiting years for the entire system, the business can start realizing value in a matter of weeks or months. For example, the first "sprint" might focus exclusively on digitizing field tickets and automating the associated invoicing workflow. This single module is developed, tested, and deployed, providing an immediate and measurable benefit to both field crews and the finance department.

This iterative approach offers profound benefits. First, it dramatically reduces project risk. By building and testing in small cycles, problems are identified and resolved early, preventing them from escalating into catastrophic failures. Second, it ensures user buy-in. End-users are involved in the process from the beginning, providing continuous feedback that shapes the development. This guarantees that the final product solves their real-world problems and is something they are eager to use. Finally, it delivers value faster. The tangible success of the first module builds organizational momentum and provides a clear justification for continued investment, creating a virtuous cycle of improvement and adoption.

The Human Factor: Mastering Change Management

Ultimately, the success of any digital transformation hinges on people. Technology can be perfected, but if the workforce is resistant or unprepared, the project will fail. Analysis shows that up to 70% of transformation initiatives stall not for technical reasons, but for human ones. For insight into why so many technology initiatives falter at this stage, review our research on manufacturing software user adoption and how organizational change management can make or break digital rollouts.

Mastering this human element requires a deliberate change management strategy. It begins with clear and unwavering executive sponsorship. The leadership team must not only approve the budget but also champion the vision, consistently communicating why the change is critical for the company's future. The entire project must be relentlessly

focused on the user. The primary goal should be to make employees' jobs easier and more effective; the technology is merely the means to that end. Finally, this process should be guided by a structured change management framework, such as Prosci's ADKAR model, which focuses on building

Awareness of the need for change, fostering a Desire to participate, providing the Knowledge and Ability to succeed, and implementing Reinforcement to make the change stick.

To provide a practical tool for leaders, the following table outlines a clear, phased implementation roadmap.

| Phase | Key Actions |

|---|---|

| Phase 1: Assessment & Discovery | - Assemble a cross-functional project team (Ops, IT, Legal, Field). - Audit current document workflows and identify all pain points. - Inventory all document types (permits, logs, drawings, etc.). - Define clear business objectives (e.g., reduce invoice cycle by 50%). |

| Phase 2: Strategic Planning | - Define scope, budget, and timeline. - Finalize the decision: COTS vs. Custom. - Select a software partner. - Develop a detailed data migration strategy. - Establish success metrics (KPIs) to track performance. |

| Phase 3: Design & Configuration | - Define user roles and access control permissions. - Design the metadata schema and folder structure. - Map out and build automated workflows (e.g., for approvals, transmittals). - Plan integrations with existing systems (ERP, CMMS). |

| Phase 4: Agile Deployment & Testing | - (Rapid Agile Deployment) Deploy the system in iterative sprints, starting with a high-value area (e.g., digital field tickets). - Conduct User Acceptance Testing (UAT) with real end-users at each stage. - Migrate data in phases, validating each batch. - Refine and adapt based on user feedback. |

| Phase 5: Training & Go-Live | - Conduct comprehensive, role-based training for all users. - Communicate the "go-live" plan and provide support resources. - Officially launch the new system. |

| Phase 6: Ongoing Support & Optimization | - Provide dedicated post-launch support. - Monitor system performance and user adoption metrics. - Regularly review and optimize workflows. - Plan for future enhancements and scalability. |

Section 5: Measuring the Return: The Tangible ROI of Going Digital

For any major capital investment, the ultimate question for an executive is: What is the return? A modern Document Management System delivers a powerful and multifaceted return on investment (ROI) that can be measured through both hard financial metrics and significant qualitative improvements to the business. Building the business case requires quantifying these gains and presenting them in a clear, compelling manner. For more on measuring results in digital transformation, see our expert analysis on maximizing ROI throughout the software lifecycle.

Quantifying the Gains: Hard Metrics and Industry Benchmarks

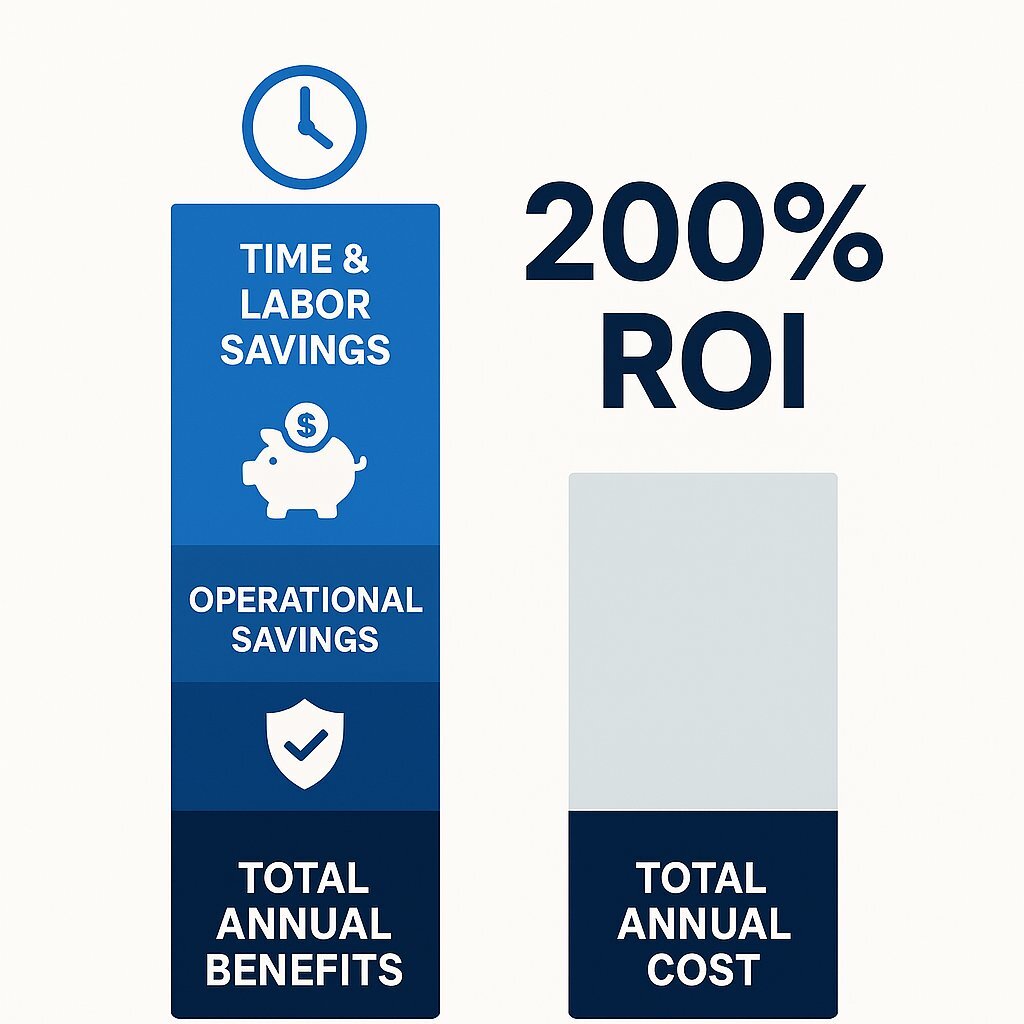

The financial return of a DMS is not speculative; it is well-documented. The fundamental formula for calculating ROI is straightforward: ROI = ((Total Benefits – Total Costs) / Total Costs) × 100. The key is to accurately quantify both sides of this equation.

Industry benchmarks provide a powerful starting point. A study by Nucleus Research found that, on average, companies realize a return of $8.55 for every dollar invested in a DMS. Research from AIIM places the average ROI in the range of 200% to 400%, while IDC has measured a 30% increase in overall productivity after a successful DMS implementation. These figures demonstrate the transformative potential of these systems.

To calculate a company-specific ROI, leaders must track a clear set of Key Performance Indicators (KPIs) before and after implementation. These metrics fall into several categories:

- Efficiency Metrics: These measure improvements in speed and throughput. Key metrics include Document Retrieval Time (DRT)—the time it takes a user to find a needed document—and Document Approval Cycle Time. Tracking these before and after implementation provides a direct measure of time saved.

- Cost Metrics: These are the most direct financial savings. They include the measurable reduction in spending on paper, printing, and physical storage, as well as the reduction in labor hours dedicated to manual filing, searching, and data entry.

- Quality & Compliance Metrics: These metrics quantify risk reduction. They include the reduction in document error rates, a decline in the number of unauthorized access attempts, the completeness of audit trails, and the overall user adoption rate of the new system.

A visual representation of this ROI can be a powerful tool for securing stakeholder buy-in. Imagine a chart that clearly illustrates the financial case. It would show a stacked bar representing the "Total Annual Benefits," with segments for "Time & Labor Savings" (e.g., $18,000), "Operational Savings" from reduced material costs (e.g., $5,000), and "Compliance Risk Reduction" (e.g., $7,000), for a total benefit of $30,000. Next to it, a much smaller bar would represent the "Total Annual Cost" of the DMS (e.g., $10,000). Prominently displayed would be the calculated ROI of 200%. This simple visual makes the financial argument undeniable: for every dollar invested, the company gets two dollars back in measurable value.

The Qualitative Payoff: Building a Resilient, Future-Proof Operation

The full value of a DMS, however, cannot be captured by financial metrics alone. The qualitative benefits are equally, if not more, important to the long-term health and resilience of the organization. If you want to see how AI-powered platforms can further amplify results, especially for energy companies focused on compliance and sustainability, read our exploration of AI-powered waste management.

- Enhanced Safety: The ability to ensure that every single field worker, on any site, has immediate access to the correct, up-to-the-minute version of a safety procedure or an engineering drawing on their mobile device is a benefit whose value is difficult to overstate. It is a direct investment in preventing incidents and protecting the workforce.

- Improved Employee Morale: The daily frustration of wrestling with inefficient processes, searching for lost documents, and performing redundant manual tasks takes a toll on employees. Streamlining these workflows with an intuitive digital system reduces this friction, leading to higher job satisfaction, better engagement, and lower turnover.

- Faster, Smarter Decisions: When managers and executives have real-time access to accurate operational data, they can move from reactive problem-solving to proactive, strategic decision-making. This agility is a critical competitive advantage in a volatile market.

- Sustainability and ESG Performance: In an era of increasing scrutiny from investors and the public, a company's Environmental, Social, and Governance (ESG) profile is a key indicator of its long-term viability. A DMS directly contributes to the "Environmental" pillar by drastically reducing paper consumption and enabling remote work, which lowers the company's carbon footprint. It supports the "Governance" pillar by ensuring robust, auditable compliance and data security.

Case in Point: Real-World Transformation

The story of Cabot Oil & Gas Corp. (now part of Coterra Energy) provides a concrete example of these benefits in action. Before implementing a DMS, the company's accounting department was inundated with paper. Invoices and supporting documents were physically mailed from field offices to corporate for filing, a process that was slow, expensive, and prone to lost documents. Audits were a stressful, time-consuming ordeal of manually retrieving, copying, and refiling thousands of papers.

After implementing a DMS, the transformation was immediate and profound. Vendor invoices became electronic, and workflows were automated. Online forms allowed field tickets to flow directly into the accounting system, where they were automatically matched with the corresponding invoices. The result? The time required to provide documents for an audit was reduced from days to mere minutes. The success was so significant that the company expanded the use of the DMS to its Marketing and Land departments, demonstrating the system's scalability and enterprise-wide value. This case study is not an outlier; it is a clear demonstration of the achievable results when an organization commits to moving beyond paper.

Conclusion: Your Next Steps Toward Operational Excellence

In the modern energy landscape—defined by intense pressure to improve efficiency, navigate complex regulations, and execute a challenging energy transition—clinging to outdated, paper-based document management is no longer a viable strategy. It is a direct and significant impediment to profitability, a constant threat to safety, and a barrier to future growth. The analysis is clear: a modern, well-implemented Document Management System is a foundational technology for achieving operational excellence. It transforms a core business function from a source of cost and risk into a driver of efficiency, intelligence, and competitive advantage.

For executives ready to lead this change, the path forward can be distilled into three immediate, actionable steps:

- Initiate an Internal Audit: The first step is to quantify the "cost of doing nothing." Task your operational and financial leaders with a simple but revealing audit. Measure the hours your teams waste searching for information. Calculate the direct annual costs of paper, printing, and off-site storage. Track the delays in your current invoicing and approval cycles. This data will form the unassailable foundation of your business case.

- Define Your Strategic Requirements: Convene a leadership group from operations, IT, finance, and legal to move beyond a simple list of features and define the strategic business outcomes you need to achieve. Do you need to accelerate cash flow? Fortify compliance and audit readiness? Empower field teams with real-time data? A clear vision of the "perfect solution" will guide your entire journey.

- Engage a Specialist Partner: The unique complexities of the energy sector—from its specialized document types to its split between field and office operations—demand more than a generic, one-size-fits-all solution. The most successful transformations are achieved by partnering with a specialist who understands the industry's DNA. Seek a partner capable of architecting a tailored technology solution that fits your precise workflows and can deliver it using a rapid, agile deployment model. For more on building resilient, adaptable solutions, visit our custom software for supply chain crisis article, which shares parallels for high-stakes, document-heavy industries. This approach ensures the project mitigates risk, delivers value quickly, and results in a system that your teams will actually embrace, unlocking the full potential of your digital transformation.

Supporting Resources

- IEA Report on Digitalisation and Energy: Provides macro-level context on the digital transformation sweeping the energy sector, reinforcing the urgency for modernization.

- McKinsey Global Energy Perspective: Offers insights into the pressures and opportunities facing the industry, highlighting the strategic importance of efficiency and data-driven operations.

- World Economic Forum - Fostering Effective Energy Transition: Discusses the broader context of resilience, security, and sustainability that a modern DMS is essential to support.

- For a deeper understanding of how digital-first strategies drive engagement and ROI in regulated sectors, see how digital transformation is reshaping patient engagement in healthcare. The parallels in compliance, data integrity, and systemic risk management are directly relevant to energy leaders.

About Baytech

At Baytech Consulting, we specialize in guiding businesses through this process, helping you build scalable, efficient, and high-performing software that evolves with your needs. Our MVP first approach helps our clients minimize upfront costs and maximize ROI. Ready to take the next step in your software development journey? Contact us today to learn how we can help you achieve your goals with a phased development approach.

About the Author

Bryan Reynolds is an accomplished technology executive with more than 25 years of experience leading innovation in the software industry. As the CEO and founder of Baytech Consulting, he has built a reputation for delivering custom software solutions that help businesses streamline operations, enhance customer experiences, and drive growth.

Bryan’s expertise spans custom software development, cloud infrastructure, artificial intelligence, and strategic business consulting, making him a trusted advisor and thought leader across a wide range of industries.