How Custom Software Solves Manufacturing’s Supply Chain Crisis

August 15, 2025 / Bryan ReynoldsThe Cost of Waiting is Over: How Custom Software Solves Manufacturing's Supply Chain Crisis

Are You Navigating the "New Normal" or Being Overwhelmed by It?

The persistent state of crisis in global supply chains is not a temporary storm to be weathered. The sequence of disruptions—from pandemics and port closures to geopolitical conflicts and climate events—represents a fundamental and permanent shift in the landscape of global commerce. The era of predictable, hyper-efficient, lean supply chains is definitively over. The new strategic reality for every manufacturing executive is an era of constant, overlapping disruptions.

Navigating this new normal requires more than incremental adjustments; it demands a radical rethinking of the technological backbone that underpins your operations. For many, the inability to adapt is no longer a minor operational headache but a direct and severe threat to the bottom line. The numbers paint a stark picture of the financial toll. An overwhelming 94% of companies report a negative revenue impact stemming directly from supply chain disruptions. For the average manufacturing company, each day of a major disruption incurs a cost of approximately

$0.61 million, a figure that skyrockets to $3.5 million per day in high-tech sectors. The cumulative effect is staggering, with disruptions shaving

6% to 10% off corporate revenues and contributing to an estimated 60% of recent inflation, a cost that ultimately impacts both your profit and loss statement and your customers' wallets.

While external disruption is now a constant, internal vulnerability is a choice. Legacy systems and standardized off-the-shelf software, designed for a bygone era of stability, have become liabilities. They lack the agility, intelligence, and bespoke connectivity required to manage today's complex and chaotic value networks. The path to resilience, agility, and sustainable competitive advantage lies in architecting a digital nervous system with custom-developed software—a solution tailored not to generic "best practices," but to the unique DNA of your operational ecosystem.

"Why Is This Happening? We've Never Been This Vulnerable Before."

To effectively combat the current volatility, executives must first understand the systemic nature of the problem. The present vulnerability is not the result of a single weak link but the catastrophic failure of an entire philosophy of supply chain management that prized efficiency above all else.

The Fragility of "Just-in-Time"

For decades, the manufacturing world was driven by the pursuit of leanness. Methodologies like just-in-time (JIT) manufacturing and minimized inventories were celebrated for their ability to slash operating costs. These systems were relentlessly optimized for a world with relatively predictable supply and demand patterns. In doing so, they created hyper-efficient but dangerously brittle supply chains, removing the very buffers and redundancies needed to absorb shocks. When stress is applied, these inflexible chains do not bend; they break.

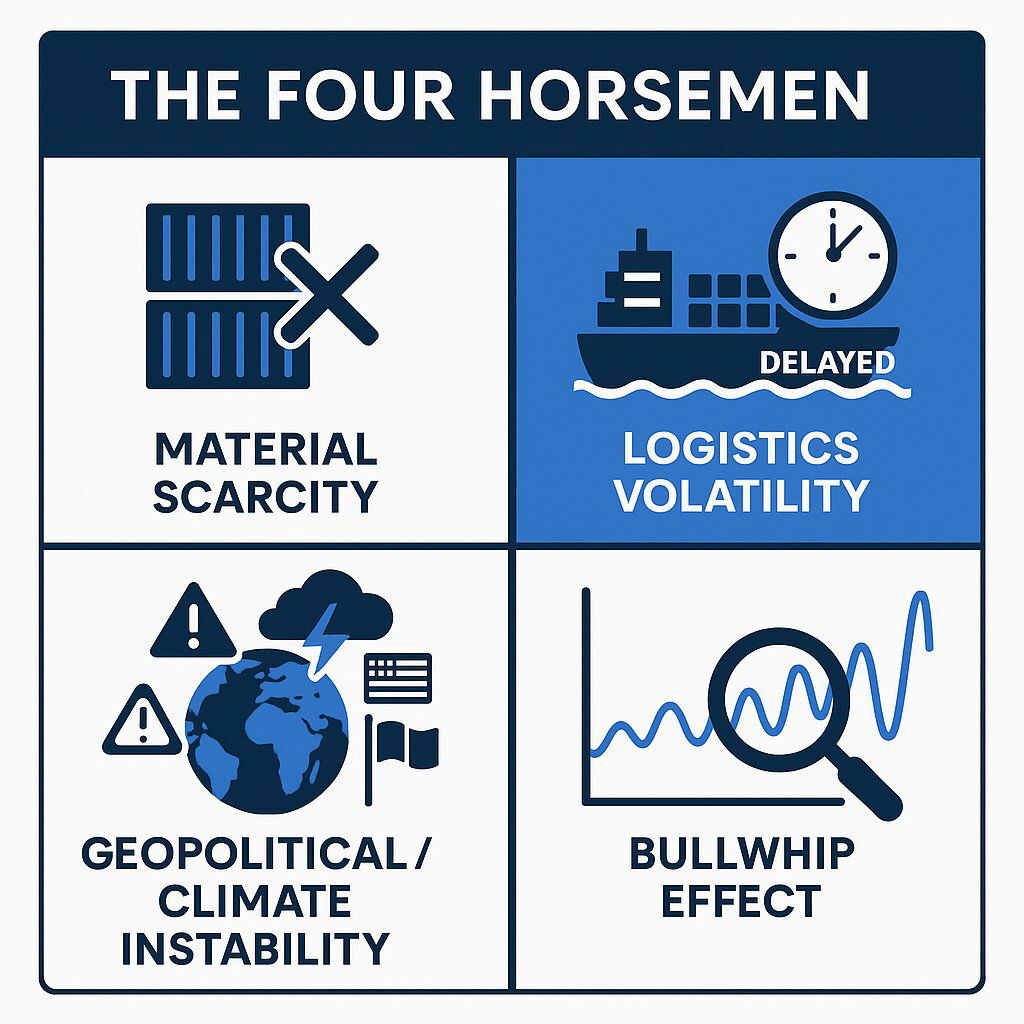

The Four Horsemen of Modern Disruption

What were once considered "black swan" events are now persistent, overlapping threats that must be factored into core business strategy.

- Material & Commodity Scarcity: The inability to secure essential inputs is now the single most-cited disruption, impacting 61% of manufacturing firms . This is not an isolated issue but a systemic challenge affecting a vast range of materials, from basic resources like lumber and plastics to critical components like semiconductors, creating headwinds for the entire global economy.

Logistics & Transportation Volatility: The physical movement of goods has become a major point of failure. The cascading effects of port congestion, container misplacement, labor shortages, and skyrocketing freight prices have created unprecedented delays. Even now, average delivery times for raw materials remain approximately

25% longer than pre-pandemic norms, forcing companies to pad schedules and carry more expensive safety stock.

Geopolitical & Climate Instability: These factors are no longer edge cases but central risks. International trade is now continuously reshaped by tariffs, regional conflicts, and national security concerns that can sever critical supply links overnight. Simultaneously, climate-related events are a growing menace,

63% of companies reporting supply chain disruptions due to climate change in 2025.

- The Bullwhip Effect on Steroids: This classic supply chain phenomenon—where minor fluctuations in consumer demand amplify into massive swings in orders as they move up the supply chain—is now dangerously supercharged. In an environment of uncertainty and poor data visibility, panic buying and precautionary inventory buildups by firms create wild oscillations, leading to severe inventory imbalances and price volatility.

The Core Internal Failure: A Crisis of Visibility

While external shocks are the trigger, they only become catastrophic because of a fundamental internal weakness: a profound lack of visibility. The most damning statistic in modern supply chain management is this: only 6% of companies have achieved full, end-to-end visibility into their supply chains.

This blindness is the root cause of the damage. The inability to see what is happening across a multi-tiered network of suppliers and partners in real time creates a critical delay between an event and a decision. This information latency is where resilience fails and costs explode. A disruption at a tier-2 supplier might go unnoticed for days or weeks in a traditional, siloed system. During this information blackout, the bullwhip effect takes hold, incorrect orders are placed, and critical buffers are depleted. By the time the C-suite is alerted, the problem has cascaded, and the cost has multiplied exponentially.

This is confirmed by manufacturers themselves, who cite a lack of common data platforms (53%) and differences in digital maturity among partners (54%) as their top obstacles to progress. The problem is not a single supplier; it is the technological failure to connect the entire ecosystem. The most valuable asset in a modern supply chain is not inventory or even supplier diversity, but

decision-making velocity. And that velocity is impossible without visibility.

Visual 1: The True Cost of Supply Chain Disruption

(An infographic for an executive audience would visually represent the following key data points to provide an at-a-glance summary of the financial stakes.)

- Headline: Your Supply Chain is Leaking Revenue.

- Key Statistics:

- 94% of companies report a negative revenue impact from disruptions.

- $1.5 Million is the average daily cost of a major disruption across industries.

- 8% of annual revenue is lost on average due to supply chain problems.

- 27% annual probability of a major, multi-year supply chain disruption.

- The Core Problem: "This happens because only 6% of companies have full end-to-end visibility into their supply chain."

"Our Current Systems Can't Keep Up. What's the Solution?"

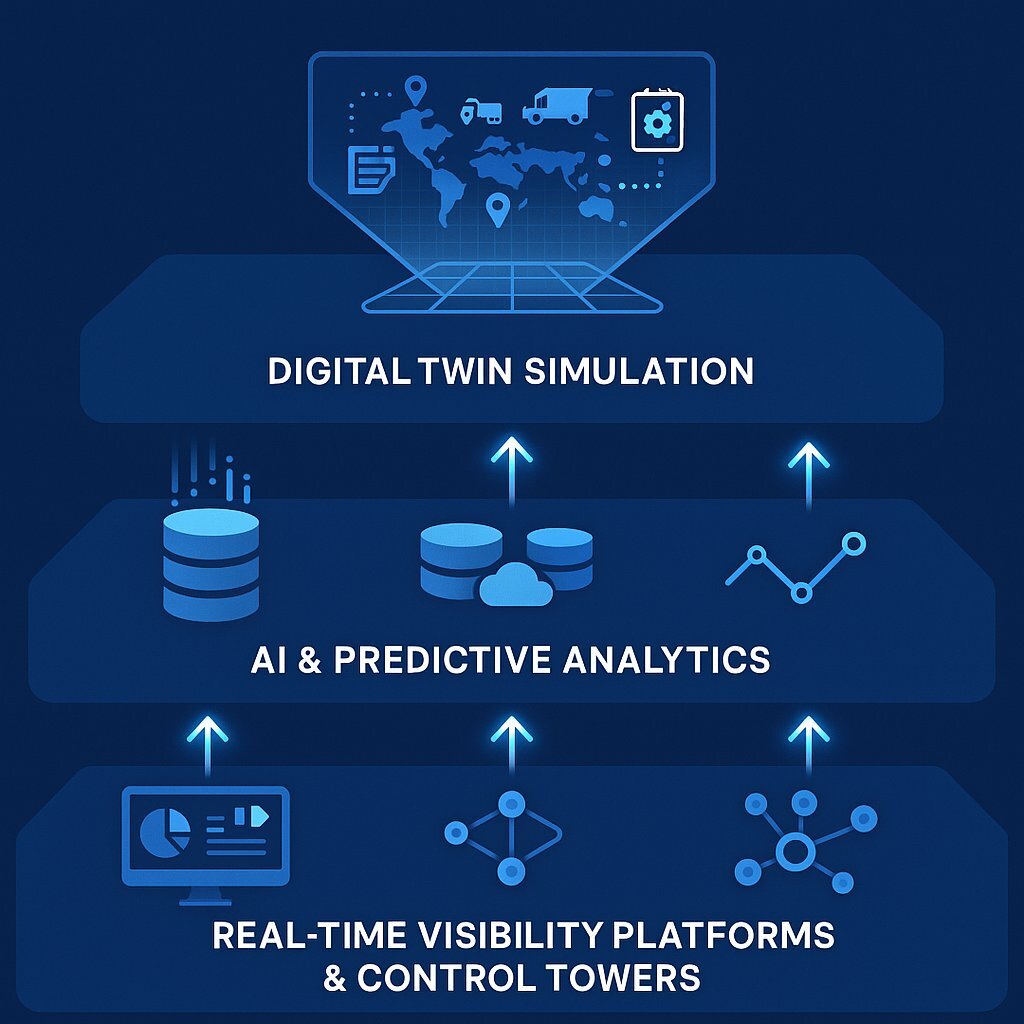

The answer to navigating this new era of disruption is not to find a better off-the-shelf Enterprise Resource Planning (ERP) system. The solution is to build a digital nervous system —an interconnected, intelligent, and bespoke software ecosystem that provides a "single source of truth" for your entire value chain. Such a system transforms a company from a passive victim of disruption into an active, intelligent orchestrator of its supply network. This is achieved through three integrated technology layers.

The Foundational Layer: Real-Time Visibility & Control Towers

The first and most critical step is to move from analyzing the past to seeing the present. This means shifting from historical, batch-processed data to a live, dynamic view of every component moving through your supply chain. This is the function of a modern

Supply Chain Control Tower.

A true control tower is not a simple dashboard. It is a centralized intelligence hub that integrates real-time data streams from all internal and external systems—your ERP, Transportation Management System (TMS), Warehouse Management System (WMS), and, crucially, the systems of your key suppliers and logistics partners.

- Business Benefit: This provides immediate, actionable intelligence. Managers can detect production bottlenecks, receive alerts on delayed shipments, and monitor inventory levels across the network as events happen, not days or weeks later. This allows for immediate, targeted responses, such as rerouting a shipment around a storm or reallocating a critical component from one factory to another, mitigating the impact of disruptions before they escalate.

The Intelligence Layer: Predictive Analytics & AI

Once you can see the present, the next step is to accurately predict the future. This is where custom-built Artificial Intelligence (AI) and Machine Learning (ML) models provide a profound strategic advantage, acting as a "weather forecast for your supply chain".

By continuously analyzing vast and diverse datasets—including your own historical performance, weather patterns, geopolitical news feeds, commodity prices, and market trends—these systems identify subtle patterns and leading indicators of disruption that are invisible to human analysts.

Business Benefit: Instead of reacting to a supplier failure, you receive an AI-driven alert weeks in advance based on the supplier's deteriorating financial health or local political instability. Instead of being surprised by a demand spike, your system forecasts it based on emerging consumer trends. This proactive capability gives executives the most valuable commodity in a crisis: time. It allows for the implementation of contingency plans before the crisis hits. The adoption of AI in supply chains is projected to grow at a compound annual growth rate (CAGR) of

45.6% through 2025, with early adopters already reporting logistics cost reductions of 15% and inventory level decreases of 35%.

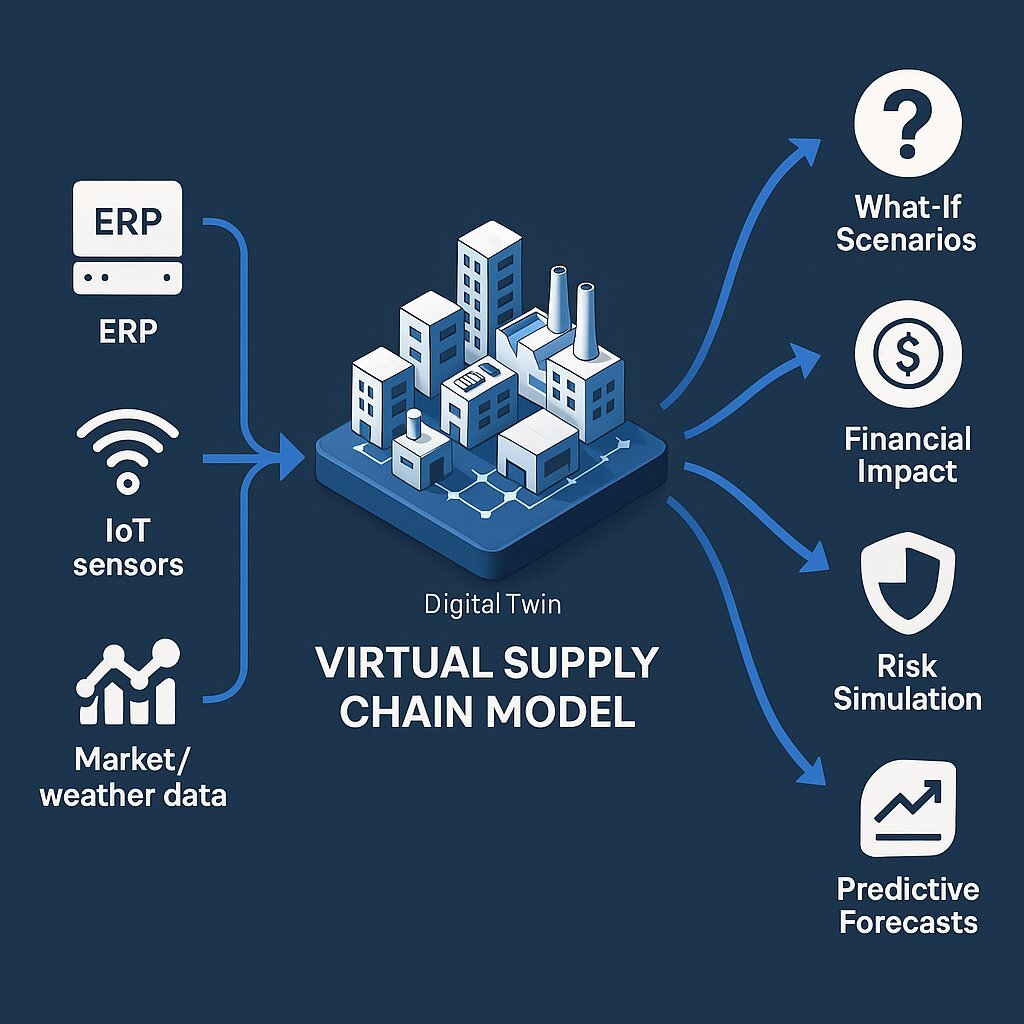

The Strategic Layer: Digital Twin Simulation

The highest level of supply chain mastery is the ability to safely test the future. A Digital Twin is a dynamic, virtual replica of your entire end-to-end supply chain. It is not a static model but a living simulation, continuously updated with real-time data from IoT sensors, ERP systems, logistics trackers, and other sources.

This creates a risk-free "sandbox" for C-suite decision-making, transforming strategic planning from a high-stakes exercise in intuition into a data-driven, iterative process.

- Business Benefit: Executives can now ask complex, strategic "what-if" questions and receive a comprehensive impact analysis in minutes, not months.

- "What is the full P&L impact if we shift 30% of our production from our factory in Asia to a new facility in Mexico?"

- "How long can our operations survive, and what will be the cost, if our primary semiconductor supplier in Taiwan goes offline for two weeks?"

- "What is the most cost-effective way to redesign our distribution network to handle a projected 20% increase in demand while minimizing our carbon footprint?" This capability is transformative. Companies that have adopted value chain digital twins have reported up to a 30% improvement in forecast accuracy and a significant acceleration in strategic decision-making.

Table 1: Matching Custom Software Solutions to Your Biggest Challenges

| Your Challenge (The Question You're Asking) | The Core Problem | The Custom Software Solution |

|---|---|---|

| "Where is my shipment right now, and why is it delayed?" | Lack of Real-Time Visibility | Real-Time Visibility Platform & Control Tower |

| "What's the risk of my key supplier failing in the next quarter?" | Inability to Predict Disruptions | AI-Powered Predictive Analytics Engine |

| "How will a new tariff affect my margins and which sourcing option is best?" | No Way to Test Scenarios | Supply Chain Digital Twin |

| "How can I better collaborate with my smaller suppliers who aren't on SAP?" | Partner Digital Maturity Gaps | Custom Supplier Collaboration Portal |

Visual 2: How a Digital Twin Works

(A simplified diagram would illustrate this flow to demystify the technology for a non-technical executive.)

- Inputs (Left Side): A series of icons representing "Real-Time Data Feeds" (ERP Systems, IoT Sensors on machinery, Transportation Management Systems, Live Market Data, Weather Forecasts) with arrows pointing toward the center.

- The Twin (Center): A central graphic labeled "Virtual Supply Chain Model," depicting a network of factories, warehouses, and transport routes.

- Outputs (Right Side): Arrows point from the central model to a series of outcomes labeled "Executive 'What-If' Scenarios," "Financial Impact Analysis," "Risk Simulation," "Predictive Forecasts," and "Optimized Action Plans."

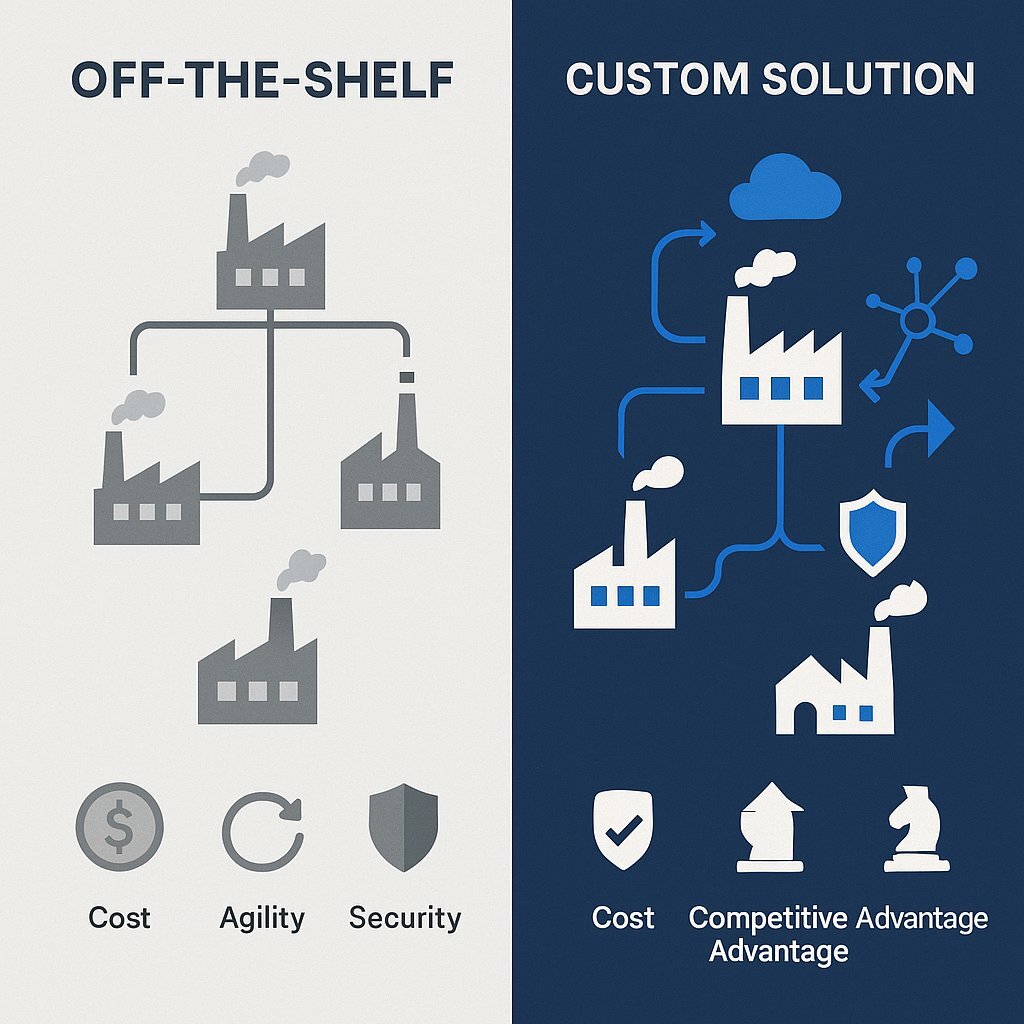

"We've Seen Off-the-Shelf Software. Why Should We Consider a Custom Solution?"

This is the central question for any executive evaluating a significant technology investment. The appeal of off-the-shelf (OTS) solutions from major vendors like SAP or Oracle is undeniable. They promise lower initial costs, rapid deployment, and the reliability that comes from a standardized, market-tested product. This line of thinking is valid, but it is rooted in a paradigm that no longer exists.

The greatest strength of OTS software in an era of stability—its standardization—is now its greatest weakness. OTS platforms are designed to optimize internal processes based on generic industry "best practices." They are fundamentally inward-looking, built to make your four walls more efficient. They were not, however, designed to manage the chaotic, unique, and externally-facing ecosystem of your specific network of suppliers, logistics providers, and contract manufacturers. In a world where 70-80% of value and risk lies outside your direct control, an inward-looking solution is insufficient.

The decision between custom and OTS is not merely a choice of software; it is a strategic choice between optimizing your company versus orchestrating your entire value ecosystem. Custom software is the only tool designed for orchestration. The following strategic comparison clarifies why.

Table 2: Custom vs. Off-the-Shelf (OTS) Software: A Strategic Comparison

| Strategic Consideration | Off-the-Shelf (OTS) Solution | Custom-Developed Solution |

|---|---|---|

| Competitive Advantage | Achieves Parity. You implement the same "best practices" as your competitors, making it difficult to create a unique operational edge. Your supply chain functions like everyone else's. | Creates Unique Advantage. Software is built around your proprietary processes and strategies, becoming a unique corporate asset that competitors cannot replicate. It hardwires your competitive edge. |

| Ecosystem Integration | Rigid & Challenging. Often requires complex, expensive workarounds to connect with legacy systems or less digitally mature partners, perpetuating the very data silos you aim to eliminate. | Seamless & Outward-Facing. Designed from the ground up to integrate flawlessly with your entire ecosystem, from a small supplier's spreadsheet to a major partner's ERP, solving the critical "digital maturity gap". |

| Flexibility & Scalability | Vendor-Locked. You are dependent on the vendor's product roadmap, feature releases, and pricing structure. The software may not adapt to your unique business needs as you grow or pivot. | Infinitely Adaptable. The software is an asset you own and control. It evolves as your business grows and your strategy shifts, making it future-proof by design. |

| Data Ownership & Security | Potential Risk. Data is often stored on third-party servers with generic security protocols. This may not meet specific industry compliance needs (e.g., FDA, HIPAA) and limits your control. | Full Control. You own the software and the data. Security protocols can be tailored to your exact business, regulatory, and geopolitical requirements, providing superior protection and control. |

| Total Cost of Ownership (TCO) | Deceptively High. A lower initial cost is often followed by high, recurring licensing fees, mandatory upgrade costs, and expensive fees for customization and integration, which accumulate over time. | Predictable & Value-Oriented. A higher upfront investment is followed by no recurring license fees. The long-term cost is more predictable and directly tied to the value it creates, often resulting in a lower TCO and a clearer ROI. |

The limitations of OTS software are not a critique of the products themselves, but an acknowledgment that they were built for a different world. In an era where resilience depends on seamless collaboration with a diverse and fragmented network of external partners, a one-size-fits-all solution is a strategic compromise. A custom solution is not just a tool; it is a platform for digitizing and strengthening the weak ties and informal relationships that OTS platforms ignore but are absolutely critical for navigating disruption. It is an investment in the resilience of your entire ecosystem, not just the efficiency of your own organization. For more on this strategic imperative, see( https://supplychainplanning.ie/hbr-article-ceos-need-to-become-supply-chain-experts/ ).

"What Does This Look Like in Practice? Show Me the Results."

The strategic argument for custom software is validated by real-world results from leading manufacturers who have made this investment. These cases demonstrate tangible, C-suite-level returns.

Case Study 1: The Digital Twin Transformation (ICP Group)

- The Problem: ICP Group, a leading US manufacturer, was grappling with high and unpredictable supply chain costs across its transportation and distribution network. Their strategic analysis was slow and expensive, as it relied heavily on external consultants to model potential changes.

- The Custom Solution: Instead of buying a generic modeling tool, ICP partnered with a firm to build a bespoke digital twin of their specific supply chain. This custom simulation model was an exact virtual replica of their unique network of facilities, routes, and product flows.

- The Result: The digital twin empowered ICP's internal team to make their own complex, data-driven decisions, eliminating their dependency on costly consultants. By running their own "what-if" scenarios, they quickly identified a 7% savings opportunity in their network. More importantly, they built a sustainable, in-house capability for continuous optimization, turning a reactive cost center into a proactive strategic function.

Case Study 2: The Ultimate Resilience Payoff (IBM)

- The Problem: IBM's vast, global supply chain was built on just-in-time principles that had become dangerously brittle. The lack of speed and transparency meant that mitigating a single component shortage was a manual, reactive process that could take up to six hours of analysis.

- The Custom Solution: IBM invested in building its own "cognitive supply chain," a custom, AI-powered platform that serves as the single, real-time source of truth for all stakeholders. This is a prime example of a bespoke, deeply integrated system designed for orchestration, not just management.

- The Result: The impact was profound. During the peak of the COVID-19 pandemic, a period of unprecedented global disruption, IBM used its cognitive supply chain to rapidly re-source and re-route parts as needed, achieving a 100% order fulfillment rate. The platform has delivered USD 160 million in savings through reduced inventory costs, optimized shipping, and massive time savings in decision-making.

Case Study 3: The Collaboration Breakthrough (Global Vehicle Manufacturer)

- The Problem: A major global manufacturer of high-value mining and construction vehicles faced a crisis where 95% of its finished vehicles were sitting idle for months due to missing components. Despite having thousands of suppliers, a lack of visibility and collaborative commitment across its multi-tier network created a critical bottleneck.

- The Custom Solution: The company implemented a custom-configured supply chain collaboration platform. This solution was not a generic portal but was tailored to create a single, shared, and actionable view of demand, supply, and commitments that worked for their entire network, from large to small suppliers.

- The Result: By directly addressing the communication and visibility gaps with a tailored solution, the manufacturer broke the component logjam. This enabled them to move vehicles from the factory lot to waiting customers, directly impacting revenue and customer satisfaction. The case highlights how custom software is uniquely capable of solving the critical "partner maturity gap" problem.

"This Seems Complex and Expensive. How Do We Ensure a Return on Our Investment?"

The final and most pressing concerns for any executive are implementation risk and cost justification. The specter of massive, multi-year IT projects that fail to deliver is a valid fear. However, modern custom software development has evolved precisely to mitigate these risks.

De-risking Development: The Agile & Cloud Advantage

The traditional "waterfall" approach to software development—where a project is planned in its entirety upfront and built over years—is obsolete for this kind of challenge. Modern development practices dramatically reduce risk and accelerate time-to-value.

- Agile Methodologies: Custom supply chain software is built using an agile approach. The project is broken down into small, manageable two- to four-week "sprints," each designed to deliver a specific, valuable piece of functionality. This iterative process allows the business to see tangible results early and often, provide continuous feedback, and ensure the final product is perfectly aligned with business needs. This approach works: companies with Agile supply chains report 85% improved risk mitigation capabilities.

- Cloud Infrastructure: Building on modern cloud platforms provides immense flexibility, scalability, and resilience without the massive upfront capital expenditure on physical servers and data centers. It allows the system to scale seamlessly with your business needs. Research shows that 60% of companies that adopt cloud for their supply chain are outperforming their competitors.

The Real ROI Calculation: The Cost of Inaction

The investment decision must be reframed. The operative question is not "Can we afford to do this?" but rather, "Can we afford not to?" The cost of inaction is no longer theoretical; it is a measurable and recurring drain on your business. With an average loss of 8% of annual revenue and a 27% chance of a major disruption each year, the status quo is prohibitively expensive. An investment in custom software is an insurance policy against these catastrophic losses and a foundational platform for future growth and efficiency. For a forward-looking perspective on the trends shaping these decisions, see(

https://www.forbes.com/sites/sap/2025/01/16/supply-chain-predictions-and-outlook-for-2025/ ).

Your First Steps: A C-Suite Playbook for Supply Chain Transformation

Embarking on this journey requires a strategic, business-first approach.

- Step 1: Define Strategic Business Objectives, Not Software Features. Begin by clearly articulating the business problem you need to solve. Is it reducing lead times by 20%? Mitigating the risk from single-source suppliers in a specific region? Improving on-time-in-full (OTIF) delivery rates to a key customer segment? The goal must be a business outcome, not a list of technologies.

- Step 2: Conduct a "Cost of Inaction" Analysis. Work with your finance team to quantify the financial impact of your current vulnerabilities. What did the last major disruption cost you in lost sales, expedited freight, and reputational damage? Compare this tangible, ongoing cost to the projected investment in a custom solution.

- Step 3: Map Your Ecosystem & Identify the Biggest Gaps. Look beyond your own walls. The most critical vulnerabilities often lie in the data and collaboration gaps between you and your key suppliers, contract manufacturers, and logistics partners. Identify the one or two most critical points of failure to target first.

- Step 4: Find a Strategic Development Partner, Not a Coder. The success of a custom software initiative depends on the partner you choose. Look for a firm that demonstrates a deep understanding of your business strategy, speaks the language of the C-suite, and utilizes modern, agile development practices to de-risk the project and deliver measurable value quickly.

Conclusion: From Surviving to Thriving in an Age of Disruption

The era of supply chain stability is over, and with it, the viability of relying on outdated systems or generic, off-the-shelf software. In today's environment, these tools are no longer assets; they are strategic liabilities that perpetuate the very blindness and information latency that lead to catastrophic failure.

The path to true, sustainable competitive advantage lies in building a bespoke digital nervous system. Custom-developed software, architected for your unique ecosystem, is the only way to achieve the three pillars of modern supply chain mastery: unparalleled visibility to see the present clearly, predictive intelligence to see the future accurately, and strategic simulation to test the future safely. For more on the technologies enabling this shift, see( Mckensey Tech Trends Outlook 2025 ).

In the new economy, supply chain disruption is the only constant. The world's leading manufacturers are no longer just managing that disruption; they are capitalizing on it. They are transforming their supply chains from a cost center into an engine for growth and a weapon of competitive advantage. The technology to do this exists. The only remaining question is one of leadership. Are you ready to build the future, or will you be disrupted by it? For more on how to build a resilient strategy, see this analysis from( https://sloanreview.mit.edu/tag/supply-chain-strategy/ ).

About Baytech

At Baytech Consulting, we specialize in guiding businesses through this process, helping you build scalable, efficient, and high-performing software that evolves with your needs. Our MVP first approach helps our clients minimize upfront costs and maximize ROI. Ready to take the next step in your software development journey? Contact us today to learn how we can help you achieve your goals with a phased development approach.

About the Author

Bryan Reynolds is an accomplished technology executive with more than 25 years of experience leading innovation in the software industry. As the CEO and founder of Baytech Consulting, he has built a reputation for delivering custom software solutions that help businesses streamline operations, enhance customer experiences, and drive growth.

Bryan’s expertise spans custom software development, cloud infrastructure, artificial intelligence, and strategic business consulting, making him a trusted advisor and thought leader across a wide range of industries.