Digital Transformation in Hazardous Waste Management: Compliance, Strategy & ROI

August 27, 2025 / Bryan Reynolds

Introduction: The Tipping Point for Hazardous Waste Management

The hazardous waste management industry is at a critical inflection point. The long-standing era of manual, paper-based compliance is over, rendered obsolete by a perfect storm of three interconnected forces: tightening global regulations, expanding corporate liability, and the rapid maturation of digital technologies. For B2B executives, this means hazardous waste management is no longer a peripheral cost center but a central strategic issue impacting risk, reputation, and profitability. In this new landscape, a proactive, technology-driven approach is the only viable path to operational resilience and competitive advantage.

This transformation is occurring against a backdrop of significant market expansion, which presents both a challenge in the form of more waste to manage and an opportunity for innovative solutions. The global hazardous waste management market is projected to grow from approximately $17.6 billion in 2024 to nearly $24.7 billion by 2030, reflecting a compound annual growth rate (CAGR) of 5.8%. The broader waste management market is on an even steeper trajectory, expected to reach approximately $2.37 trillion by 2033. This growth is fueled by increasing industrialization and a global push toward a circular economy, where waste is viewed as a resource.

This report will analyze the new regulatory landscape that is compelling this change, explore the technological solutions that enable businesses to thrive within it, and provide a clear-eyed assessment of the strategic and financial return on investment (ROI) that a modern approach delivers.

The Regulatory Gauntlet: A Rising Tide of Complexity and Cost

Businesses today face three primary regulatory waves that are converging to create an environment of unprecedented complexity. These are not isolated challenges but part of a unified global trend toward greater transparency and accountability, demanding a holistic and technology-forward response.

The Digital Mandate: California's e-Manifest as a Harbinger of Change

The U.S. Environmental Protection Agency's (EPA) electronic manifest (e-Manifest) system represents a fundamental shift in compliance, moving the industry from paper to pixels. Enforced with particular rigor by agencies like California's Department of Toxic Substances Control (DTSC), the system replaces traditional paper manifests with a centralized digital platform, RCRAInfo, for real-time, "cradle-to-grave" tracking of hazardous waste. This is not merely a matter of convenience; it is about creating an immutable, auditable digital trail that increases transparency and accountability for every party in the waste management chain.

The transition is now mandatory, with critical deadlines in 2025. As of January 22, 2025, Large Quantity Generators (LQGs) and Small Quantity Generators (SQGs) are required to register for e-Manifest and will no longer receive signed paper manifests back from treatment, storage, and disposal facilities (TSDFs). A hard stop is coming after December 1, 2025, when the EPA will no longer accept obsolete 5-copy paper forms. Furthermore, crucial compliance documents, such as unmanifested waste reports and discrepancy reports, must be submitted electronically through the system.

The cost of failing to adapt is staggering. In California, simply omitting required information from an Annual Facility Report can trigger penalties of up to $70,000 per violation, per day. Federal criminal provisions under the Resource Conservation and Recovery Act (RCRA) are even more severe, with potential fines of $50,000 per day and up to five years in prison for knowing violations—penalties that double for subsequent offenses. This transforms compliance from a routine procedural task into a high-stakes financial and legal imperative.

The Expanding Horizon of Responsibility (Part 1): Extended Producer Responsibility (EPR)

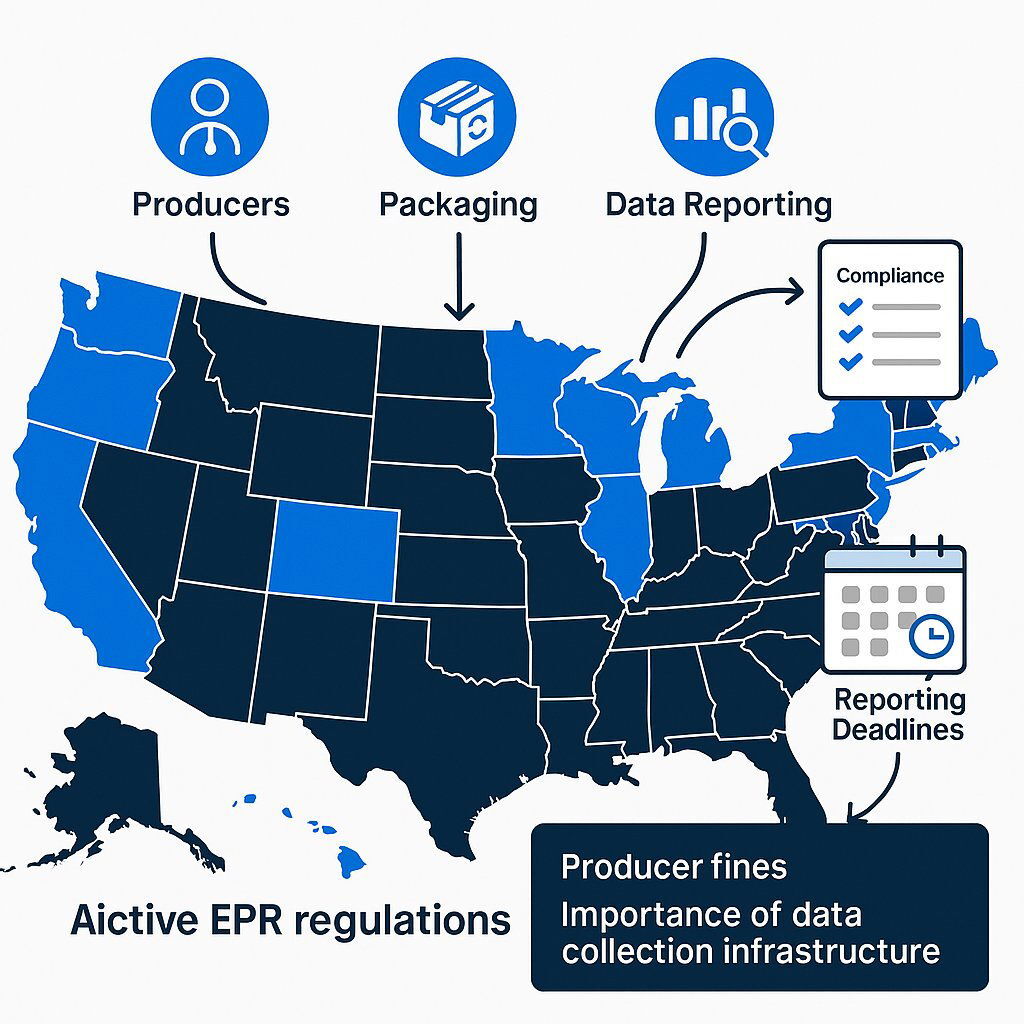

A parallel regulatory movement is fundamentally redefining corporate liability through Extended Producer Responsibility (EPR). This policy model shifts the financial and operational burden for end-of-life product management from municipalities and taxpayers to the producers themselves. This represents a paradigm shift, making companies accountable for the entire lifecycle of their products and packaging.

A growing number of U.S. states—including California, Colorado, Oregon, Minnesota, Maine, Maryland, and Washington—have enacted EPR laws, creating a complex "patchwork" of regulations that businesses must navigate. Each state has its own unique set of deadlines, exemptions, and reporting requirements, creating a significant compliance challenge for companies operating nationwide. For instance, producers in Oregon were required to submit their first reports by March 31, 2025, while Colorado's deadline for 2024 packaging data is July 31, 2025.

Compliance necessitates that producers join a Producer Responsibility Organization (PRO), such as the Circular Action Alliance (CAA), and submit highly detailed data on the specific types and quantities of packaging materials they place into the market. This requires a robust data collection and management infrastructure that most companies currently lack, moving far beyond simple sales figures to granular material tracking. The penalties for failure are severe, with fines reaching up to $50,000 per day in states like California, underscoring the financial risks of inaction.

The Expanding Horizon of Responsibility (Part 2): The ESG Imperative (CSRD)

The third major regulatory force is the European Union's Corporate Sustainability Reporting Directive (CSRD), a standard-setter with a global reach that extends far beyond Europe's borders. The directive applies to non-EU companies with substantial EU-generated revenue (over €150 million) or significant operations within the EU, impacting an estimated 50,000 companies worldwide.

Under the accompanying European Sustainability Reporting Standards (ESRS), companies are mandated to report on the environmental and social impacts of their entire value chain. This principle of "double materiality" requires organizations to conduct a dual analysis: they must assess their own impact on people and the environment (impact materiality) while also evaluating how sustainability issues create financial risks for the company (financial materiality).

These broad ESG requirements are directly linked to hazardous waste management. Reporting under standards for Pollution (ESRS E2) and Resource use and circular economy (ESRS E5) directly implicates how a company manages its hazardous byproducts, waste streams, and end-of-life products. This data must be comprehensive, third-party audited, and submitted in a machine-readable digital format, making robust data systems non-negotiable. The penalties for non-compliance, set by individual EU member states, are designed to be dissuasive and can be severe, reaching up to €10 million or 5% of a company's annual turnover in Germany, for example.

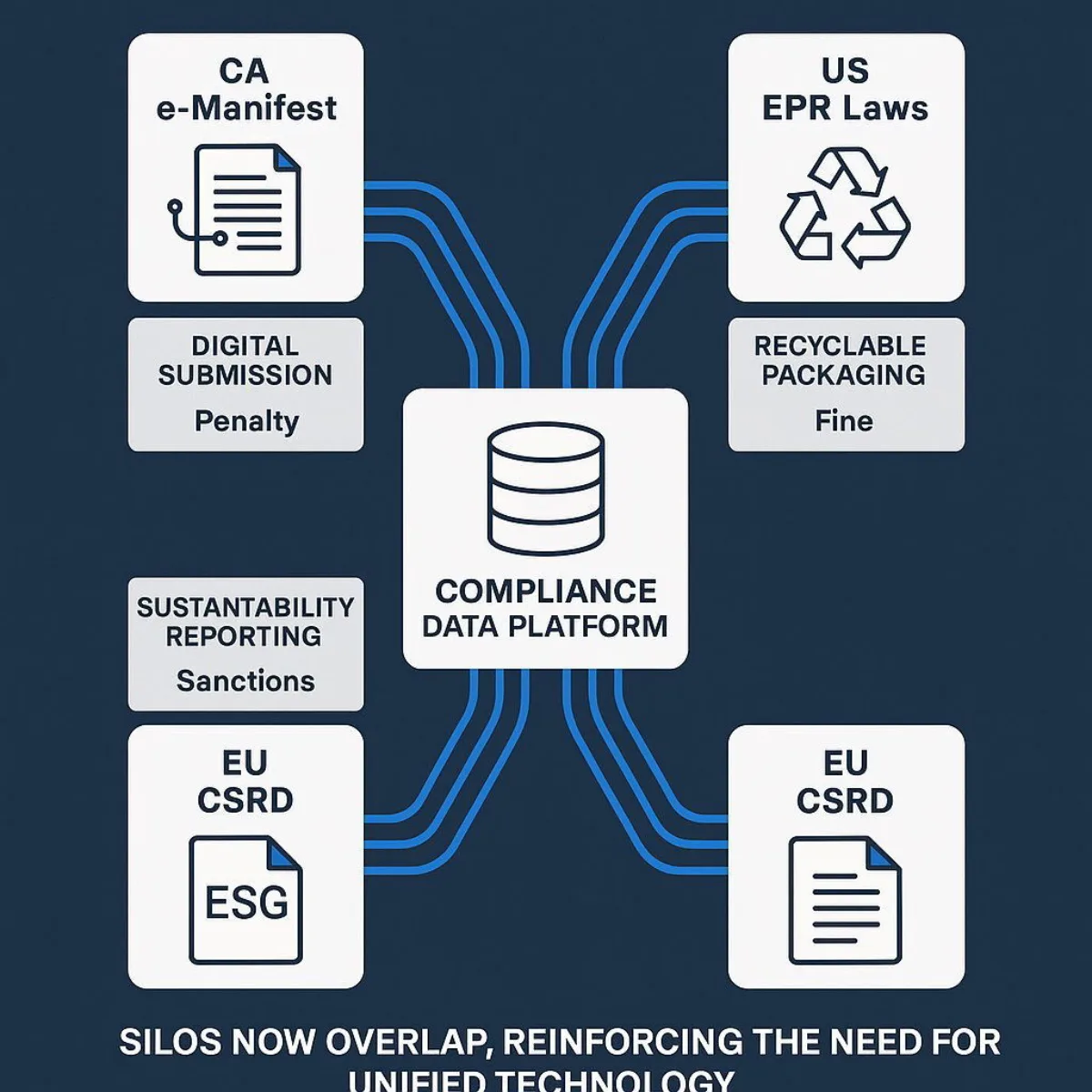

These frameworks are not siloed challenges but are deeply interconnected. The data required for EPR, such as the tonnage of specific plastics used in packaging, is a foundational component of the broader reporting required under CSRD's ESRS E5 on resource use. Similarly, the digital, auditable records generated by the e-Manifest system provide the verifiable proof needed to substantiate claims made in both EPR and CSRD reports. This convergence means that a system built for one regulation will be insufficient for the others; a unified data architecture is the only logical path forward. This shift also redefines the nature of compliance data. What was once a summary report filed to avoid a fine has become a granular, real-time stream of information that offers deep operational insights. By tracking waste generation back to its source—a specific production line or process—companies can move beyond simply managing waste to actively reducing it, a key goal of forward-thinking policies like California's 2025 Hazardous Waste Management Plan. The data mandated for compliance is now the very same data needed for process optimization and achieving circular economy goals.

| Regulation | Core Mandate | Key Business Impact | Critical Deadlines | Sample Penalty for Non-Compliance |

|---|---|---|---|---|

| CA e-Manifest (RCRA) | Mandatory digital "cradle-to-grave" tracking of hazardous waste. | Requires real-time digital tracking systems and integration with the federal RCRAInfo platform. | Jan/Dec 2025 | Up to $70,000 per day, per violation |

| U.S. EPR (e.g., CA SB 54) | Producers assume financial and operational liability for product end-of-life. | Demands precise product and packaging data collection and reporting to a PRO. | Phased 2025-2027 | Up to $50,000 per day |

| EU CSRD (ESRS) | Auditable public reporting on value chain environmental and social impacts. | Necessitates a comprehensive ESG data infrastructure for the entire supply chain. | Phased 2025-2029 | Up to 5% of annual turnover (Germany) |

The Technology Response: From Reactive Compliance to Proactive Control

Navigating this new regulatory environment requires a strategic pivot from reactive, manual processes to proactive, technology-enabled control. The right digital tools are no longer a luxury but an essential enabler for mitigating risk, ensuring compliance, and unlocking operational value.

The Digital Backbone for Modern Compliance: Custom vs. Off-the-Shelf

The interconnected nature of modern regulations demands a centralized digital platform—a single source of truth—that can manage data for e-manifesting, EPR, and CSRD reporting in a unified manner. The days of relying on disparate spreadsheets are over; such methods are fraught with risk, prone to error, and simply cannot scale to meet the new requirements.

This leads to a critical technology decision: choosing between an off-the-shelf (OTS) software package and a custom-built solution. OTS products can offer rapid deployment for standardized needs. However, they often lack the flexibility to adapt to the unique, state-by-state variations in regulations or to integrate seamlessly with a company's existing legacy ERP and supply chain systems.

For a challenge as complex and high-stakes as multi-faceted hazardous waste compliance, a custom solution often provides a superior strategic advantage. It can be precisely tailored to a company's specific waste streams, unique operational workflows, and the particular regulatory "patchwork" it faces. If you’re wondering how custom software can address these pain points, take a look at How Custom Document Management Systems Transform Energy Operations for insights into real-world digital transformation and ROI in another complex, regulated sector.

Baytech Consulting can architect a solution that not only meets today's compliance mandates but is also built to be scalable and adaptable for the inevitable regulatory changes of tomorrow. By integrating directly with core business systems, a custom platform can automate data collection, transforming compliance from a disruptive manual burden into a seamless, efficient background process.

Mobilizing the Front Lines: Real-Time Data from the Field

The integrity of the entire compliance chain hinges on the quality of data captured at its origin: the moment a waste container is filled, sealed, and labeled on the plant floor or in the field. Manual, paper-based field processes are a primary source of the data entry errors, misclassifications, and incomplete records that can cascade into costly violations.

Modern mobile applications provide a powerful solution to this "point of origin" problem. Empowering field personnel with intuitive apps on a phone or tablet allows them to instantly generate compliant labels, follow digital checklists, attach photographic evidence, capture electronic signatures, and initiate e-manifests on the spot. This ensures that data is accurate, standardized, and entered into the central compliance system in real-time, which eliminates the risks of transcription errors and the inefficiencies of double-handling paper documents. These mobile apps are not standalone tools; they are the endpoints of the central digital backbone. Data captured in the field can automatically trigger approval workflows, notify supervisors of potential issues, and populate regulatory reports, creating a seamless and auditable flow of information from the operational front lines to executive dashboards.

To truly maximize that data flow, organizations should consider integrated digital-first platforms with real-time analytics—a point explored in depth for another compliance-heavy sector in How Digital-First Software is Transforming Patient Engagement & ROI in Healthcare. Lessons from healthcare about mobile, user-centric design, and instant reporting have clear parallels here.

Engaging the Human Element: Gamified Training for a Culture of Compliance

Even with flawless technology, human error remains a significant compliance risk. Inadequate training on the complex procedures for handling, labeling, and storing hazardous materials can lead to serious safety incidents and severe regulatory violations. Traditional training methods for these often-dry topics—such as lectures or static presentations—frequently suffer from low employee engagement and poor knowledge retention.

Gamification offers a high-impact solution to this challenge. It is the application of game-like elements—such as points, badges, leaderboards, and interactive challenges—in non-game contexts like corporate training to boost motivation, engagement, and learning. This approach is effective because it taps into fundamental psychological drivers: it activates the brain's reward system, leverages a natural competitive drive, and provides the instant feedback loops that are crucial for skill development.

In the context of hazardous waste management, this translates into dynamic, hands-on learning experiences. Instead of passively listening to a presentation on spill response, employees could engage in a realistic virtual reality simulation. Rather than reading a dense manual on safety protocols, they could work together to solve challenges in a virtual "escape room" based on those policies. Compliance quizzes on waste code identification can be transformed from a test into a friendly competition. This interactive approach leads to higher course completion rates and demonstrably better retention of critical safety and compliance information. Case studies have shown that well-designed gamified safety training can lead to measurable improvements in behavior, such as a 30% reduction in safety violations.

Forward-thinking organizations are looking at similar digital learning techniques to maximize both engagement and compliance. For a look at how gamified, human-centric approaches are evolving, see ChatGPT Ate My Brain: The Hidden Cost of Outsourcing Thinking—exploring the balance between automation, digital tools, and real human learning and expertise.

The deployment of these advanced technologies fundamentally changes the nature of work on the front lines. The role of a "waste handler" is evolving into that of a "data technician." Where an employee once moved a barrel and filled out a paper form, they now use a mobile device to scan barcodes, select waste codes from a digital menu, and certify an electronic manifest. This requires a new skillset centered on digital literacy and an understanding of how their data input directly impacts the company's overall compliance posture. Consequently, companies cannot simply deploy technology; they must invest in modern training that builds digital competency. This makes innovative methods like gamification an essential component of a successful technology rollout, not just an optional extra.

Furthermore, a well-designed custom software platform becomes more than a compliance tool; it becomes a strategic moat. While competitors using one-size-fits-all OTS software are constrained by a vendor's development roadmap, a company with a custom solution can adapt with agility. When a new state enacts a unique EPR law, a new reporting module can be developed and deployed rapidly. This agility allows the company to mitigate regulatory risk more effectively and achieve deeper operational efficiencies than its peers, turning the software investment from a cost center into a durable competitive advantage. For more on how custom tech can drive advantage in industries facing legacy process challenges, you might also enjoy Why Manufacturing Teams Resist Software—and How to Overcome It.

The Strategic Payoff: Quantifying the ROI of a Modern Waste Management Strategy

For executives, the decision to invest in a digital transformation of waste management must be grounded in tangible business outcomes. The strategic payoff is clear and quantifiable, extending far beyond simple cost avoidance to include direct operational savings, enhanced corporate value, and long-term business resilience.

The Financial Case for Investment: Beyond Cost Avoidance

A modern, integrated waste management platform delivers a compelling return on investment by attacking costs and creating value across the organization. The financial case is built on two pillars: direct savings and value enhancement.

First, automated systems generate significant operational efficiencies. Studies and case studies show that integrated platforms can reduce overall operational costs by 30% and cut the specific costs associated with reporting by up to 40%. The time employees spend on manual compliance tasks can be reduced by 50-70%, freeing them to focus on higher-value activities. At the same time, the system helps the company avoid the steep penalties associated with non-compliance. Research shows that the cost of non-compliance is, on average, 2.71 times higher than the cost of compliance. With fines reaching as high as $70,000 per day for a single violation, one prevented incident can often pay for the entire software investment.

Second, these systems actively enhance revenue and corporate value. For example, AI-powered sorting technologies can improve the purity of recovered materials, increasing their market value and turning a waste stream into a revenue stream. Perhaps most importantly, the auditable data generated by a robust compliance system provides the verifiable proof of a strong Environmental, Social, and Governance (ESG) posture. This is critical for attracting capital in today's market, where ESG leaders have been shown to achieve 8% higher market returns than their peers. And while this article focuses on hazardous waste, the same ROI logic applies across multiple compliance-driven fields—from healthcare, to construction, to energy.

The evidence from real-world implementations is compelling. One industrial facility saved an estimated $365,000 annually on air monitoring with an automated system that paid for itself in just three months. A portfolio of automotive facilities using ERA Environmental Management Solutions' software saved over $190,000 per year on average. In another case, an AI-powered waste analytics system helped a recovery facility identify a £1.6 million opportunity in what was previously considered a residue line.

| Investment Area | Key Function | Quantifiable Financial Return |

|---|---|---|

| Custom Compliance Platform (e.g., from Baytech Consulting ) | Centralized data management & automated reporting. | Up to 40% reduction in reporting costs ; 30% reduction in operational costs ; Avoids non-compliance costs 2.71x higher than compliance investment. |

| Mobile Field Applications | Real-time, accurate data capture at the source. | 50% improvement in incident reporting speed ; Reduces data entry errors, avoiding potential fines of up to $70k/day. |

| Gamified Employee Training | Reduced human error & improved knowledge retention. | 30% drop in safety violations ; Reduces risk of incidents and associated legal/compensation costs. |

Building a Resilient and Reputable Enterprise

Beyond the immediate financial returns, a modern waste management strategy builds a more resilient and reputable enterprise. An adaptable, custom-built compliance system acts as a form of strategic insurance, "future-proofing" the business by allowing it to respond quickly to the next wave of regulations without facing costly operational disruptions or market access issues.

In an era of heightened stakeholder scrutiny, a demonstrable commitment to environmental stewardship is a powerful brand asset. The transparent, auditable data generated by a robust digital system provides the concrete proof needed to build trust with customers, attract and retain top talent, and satisfy the rigorous due diligence of ESG-focused investors. Ultimately, this transforms the nature of compliance. The data required by regulators ceases to be a burden and becomes a source of business intelligence, offering deep insights into operational efficiency, supply chain risks, and new opportunities for innovation within the growing circular economy. To see how this data-driven approach is revolutionizing supply chains and compliance beyond the waste sector, our guide on manufacturing's supply chain crisis provides essential perspective.

Conclusion: Your Next Move in the Digital Waste Ecosystem

The hazardous waste management landscape has been irrevocably altered. A convergence of digital-first regulations, expanding producer liability, and global ESG standards has transformed a once-siloed operational task into a core strategic challenge. Staying compliant and competitive is now fundamentally a technology and data challenge—requiring not just the right tools, but the right implementation, integration, and support.

The path forward is not through incremental improvements to outdated processes but through a comprehensive digital transformation. This involves creating a centralized digital backbone to manage data holistically, empowering field teams with mobile tools to ensure accuracy at the source, and engaging the entire workforce through innovative training methods that build a durable culture of compliance. For leadership teams seeking guidance on the integration process itself, see our roadmap for How Do We Get Started and Integrate AI? A Practical Guide for B2B Executives—which, although focused on AI, offers practical wisdom for any large-scale digital upgrade.

Navigating this complexity requires specialized expertise. The most effective next step for executive teams is to partner with a firm that possesses a deep understanding of both the intricate regulatory landscape and the vast technological possibilities. An expert partner like Baytech Consulting can collaborate with leadership to design and implement a custom software solution that transforms hazardous waste management from a source of risk and cost into a powerful driver of efficiency, resilience, and lasting strategic advantage.

About Baytech

At Baytech Consulting, we specialize in guiding businesses through this process, helping you build scalable, efficient, and high-performing software that evolves with your needs. Our MVP first approach helps our clients minimize upfront costs and maximize ROI. Ready to take the next step in your software development journey? Contact us today to learn how we can help you achieve your goals with a phased development approach.

About the Author

Bryan Reynolds is an accomplished technology executive with more than 25 years of experience leading innovation in the software industry. As the CEO and founder of Baytech Consulting, he has built a reputation for delivering custom software solutions that help businesses streamline operations, enhance customer experiences, and drive growth.

Bryan’s expertise spans custom software development, cloud infrastructure, artificial intelligence, and strategic business consulting, making him a trusted advisor and thought leader across a wide range of industries.