How Robotics and Drones are Revolutionizing Construction: An Executive Guide

August 26, 2025 / Bryan Reynolds

The construction industry is navigating a perfect storm. A persistent skilled labor shortage is colliding with immense pressure to deliver projects faster and more profitably, all while navigating razor-thin margins and increasingly stringent safety protocols. For executives, these are not abstract challenges; they are daily realities that threaten timelines, budgets, and the bottom line. In this high-stakes environment, clinging to traditional methods is no longer a viable strategy.

The solution is not a futuristic fantasy; it is a tangible reality on job sites today. Robotic automation and unmanned aerial vehicles (UAVs), or drones, have evolved from novelties into proven, strategic tools that directly address the industry's most pressing challenges. They represent a fundamental shift in how we build. However, the true, sustainable competitive advantage is not found in the hardware alone. It is unlocked through a cohesive and sophisticated software and data integration strategy that turns raw site data into actionable, enterprise-wide intelligence.

This guide is written for the construction executive. Following the 'They Ask You Answer' approach, it will directly address the most critical questions you have about this technological revolution. What can these machines actually do? What is the real, bottom-line return on investment (ROI)? How do these disparate technologies work together? And most importantly, how can your firm begin this transformation?

What Specific Jobs Can Robots and Drones Actually Do on a Construction Site?

The hype surrounding automation can be overwhelming. To make strategic decisions, executives need to move past the buzz and understand the specific, value-adding tasks these technologies perform. The modern construction site is becoming a two-tiered automated environment: ground-based robots executing physically demanding work, and aerial drones providing total site awareness.

On the Ground: The Rise of the Robotic Workforce

Ground-based robots are designed to automate tasks that are repetitive, physically demanding, and dangerous, directly augmenting the capabilities of your existing workforce and mitigating risks.

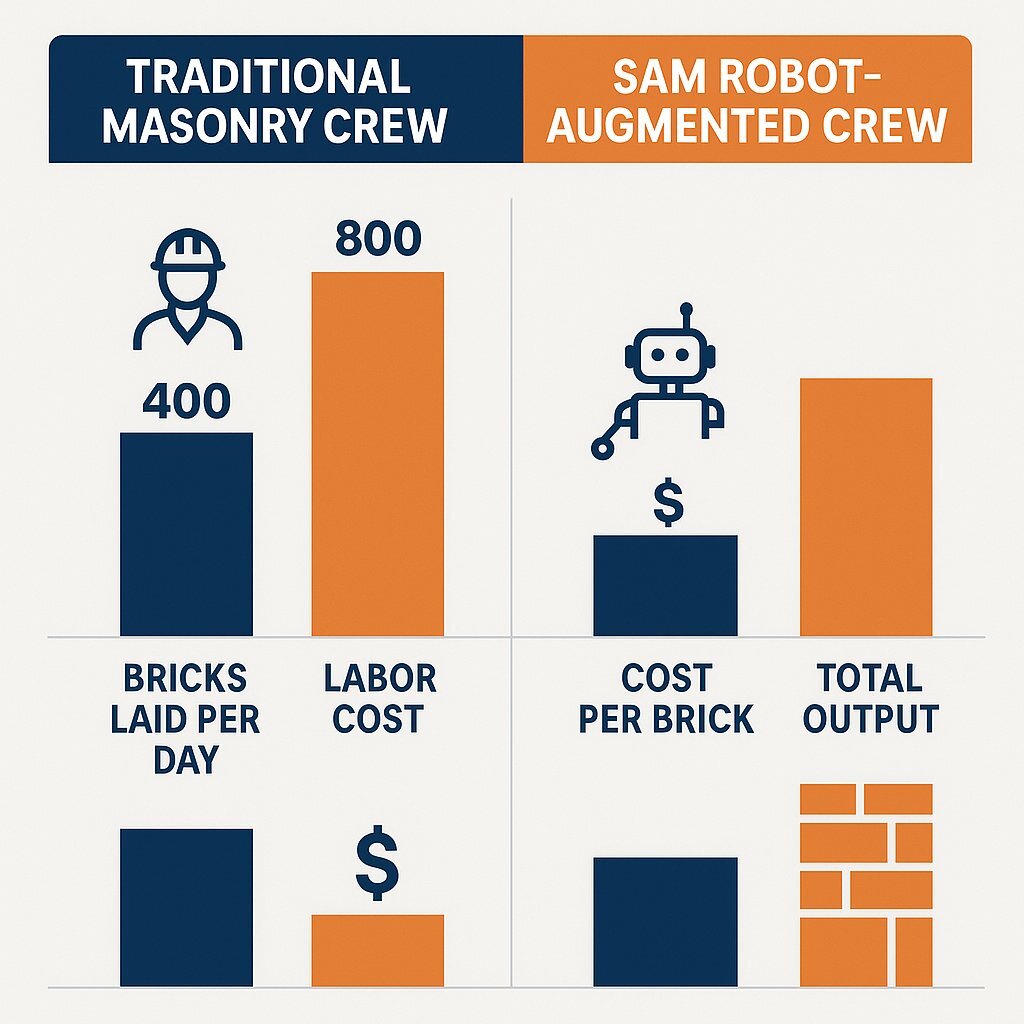

- Bricklaying: The quintessential example is the Semi-Automated Mason, or SAM. This is not a machine that replaces masons but a collaborative robot, or "cobot," that works alongside them. A human mason can lay approximately 500 bricks per day; a single SAM unit, operated by a trained mason, can lay between 2,000 and 3,000 bricks in the same timeframe. This five-fold increase in productivity doesn't eliminate jobs; it amplifies the output of skilled workers, allowing a crew to accomplish more and enabling masons to focus on quality control and complex detail work that requires human expertise. Globally, companies like Australia's Fastbrick Robotics are pushing the envelope even further with machines like the Hadrian X, which is capable of laying over 1,000 bricks per hour.

- Material Handling: The physical strain of construction work is a leading cause of injury and attrition. Lift-assist technology directly addresses this. The Material Unit Lift Enhancer (MULE) is a prime example—a robotic arm that allows a single worker to handle and place materials weighing up to 150 lbs with ease. This technology not only reduces the risk of musculoskeletal injuries but also improves efficiency by minimizing the manpower needed for heavy lifting tasks.

- Other Key Tasks: The applications for ground robots extend across the job site. Vision-equipped articulated robots can automate the physically demanding and repetitive process of tying rebar. Others are being deployed for welding structural steel, performing demolition in confined or hazardous spaces, and even 3D printing entire structures layer-by-layer from concrete.

The common thread through these applications is not the replacement of human workers but their augmentation. By automating the most strenuous and repetitive tasks, robotics elevates the role of the human worker from a manual laborer to a skilled technology operator and quality assurance supervisor. This shift makes existing crews more productive and can help attract new, tech-savvy talent to an industry struggling with an aging workforce.

In the Air: The Drone's-Eye View for Total Site Awareness

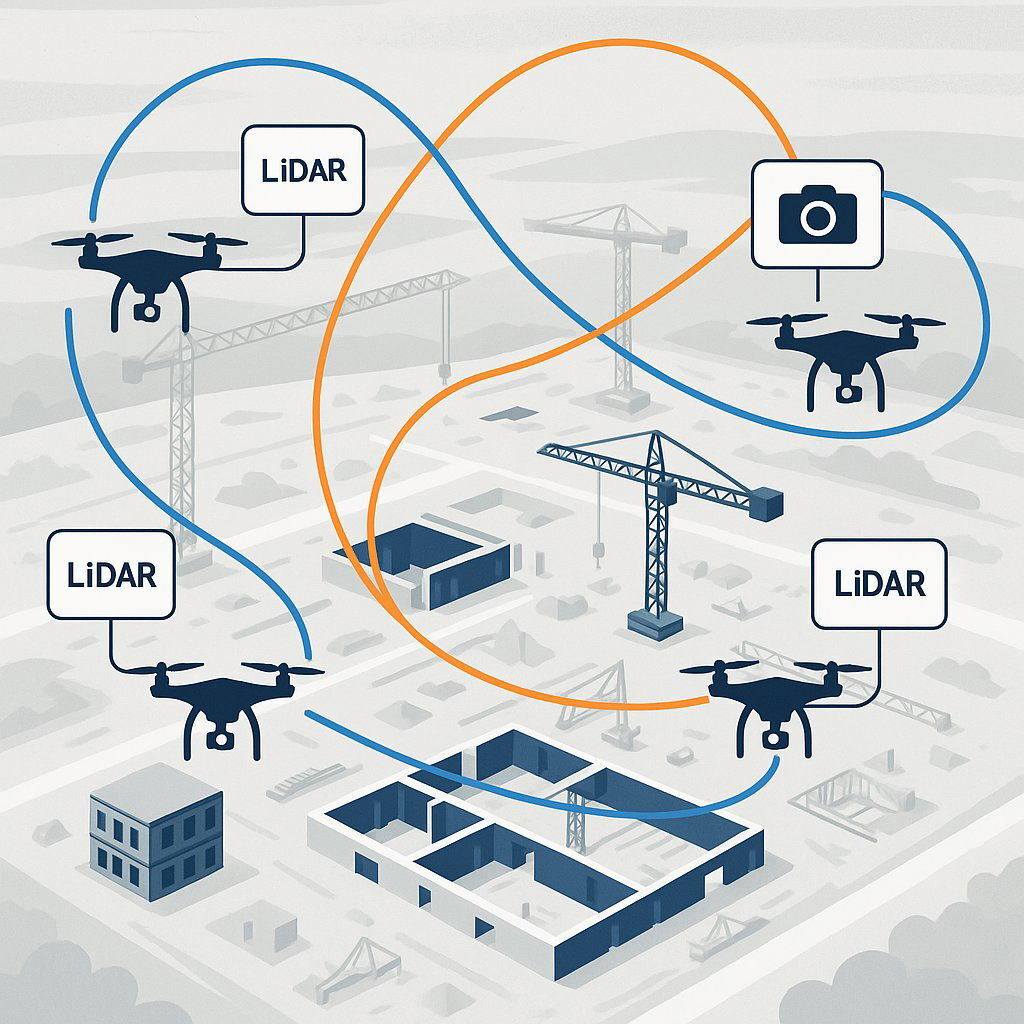

While ground robots execute tasks, drones have become the indispensable data-gathering tools that provide a level of site intelligence previously impossible or prohibitively expensive.

- Surveying & Mapping: Traditionally, a topographical survey of a construction site is a time-consuming and expensive process involving ground crews and specialized equipment. Drones equipped with high-resolution cameras and Light Detection and Ranging (LiDAR) sensors can perform these surveys up to five times faster than terrestrial methods, reducing survey time by as much as 80%. They capture thousands of images which are then processed by photogrammetry software to generate highly accurate 2D orthomosaic maps and 3D models of the site, providing a precise digital foundation for the entire project.

- Progress Monitoring: Regularly scheduled, autonomous drone flights create a consistent, visual timeline of the project. This "as-built" data can be compared against project schedules and designs to track progress with objective accuracy, identify potential bottlenecks early, and keep stakeholders informed with rich visual updates without requiring constant site visits.

- Inspections & Safety: Drones can safely inspect hard-to-reach or hazardous areas like roofs, building facades, bridges, and scaffolding, significantly reducing the risk of falls and other accidents for human inspectors. When equipped with thermal cameras, they can detect insulation problems, water leaks, or electrical faults that would be invisible to the naked eye.

- Inventory Management: Accurately measuring the volume of aggregate stockpiles is a critical but often imprecise task. Drones can fly over material piles and, using 3D modeling software, calculate their volume with a high degree of accuracy. This provides project managers with crucial, up-to-date data for resource allocation, preventing material shortages or costly over-ordering.

These two domains—ground robotics and aerial drones—are not separate technological silos. They are two halves of a comprehensive site digitization strategy. The drone provides the macro-level, "big picture" intelligence of the entire site, mapping the terrain and tracking overall progress. The ground robot operates at the micro-level, executing specific physical tasks within that digitally mapped environment. The powerful synergy emerges when the aerial intelligence from the drone (e.g., an accurate 3D map of the as-poured foundation) is used to inform the programming and navigation of the ground robot (e.g., precisely where the bricklaying robot should set up). This creates a feedback loop where aerial data directs ground-level execution, a capability that hinges on a sophisticated, integrated software layer.

What is the Real Business Case? Unpacking the ROI of Construction Automation

For any executive, the decisive question is about the bottom-line impact. A compelling business case for automation must be built on hard data, demonstrating not only cost savings and productivity gains but also significant risk reduction.

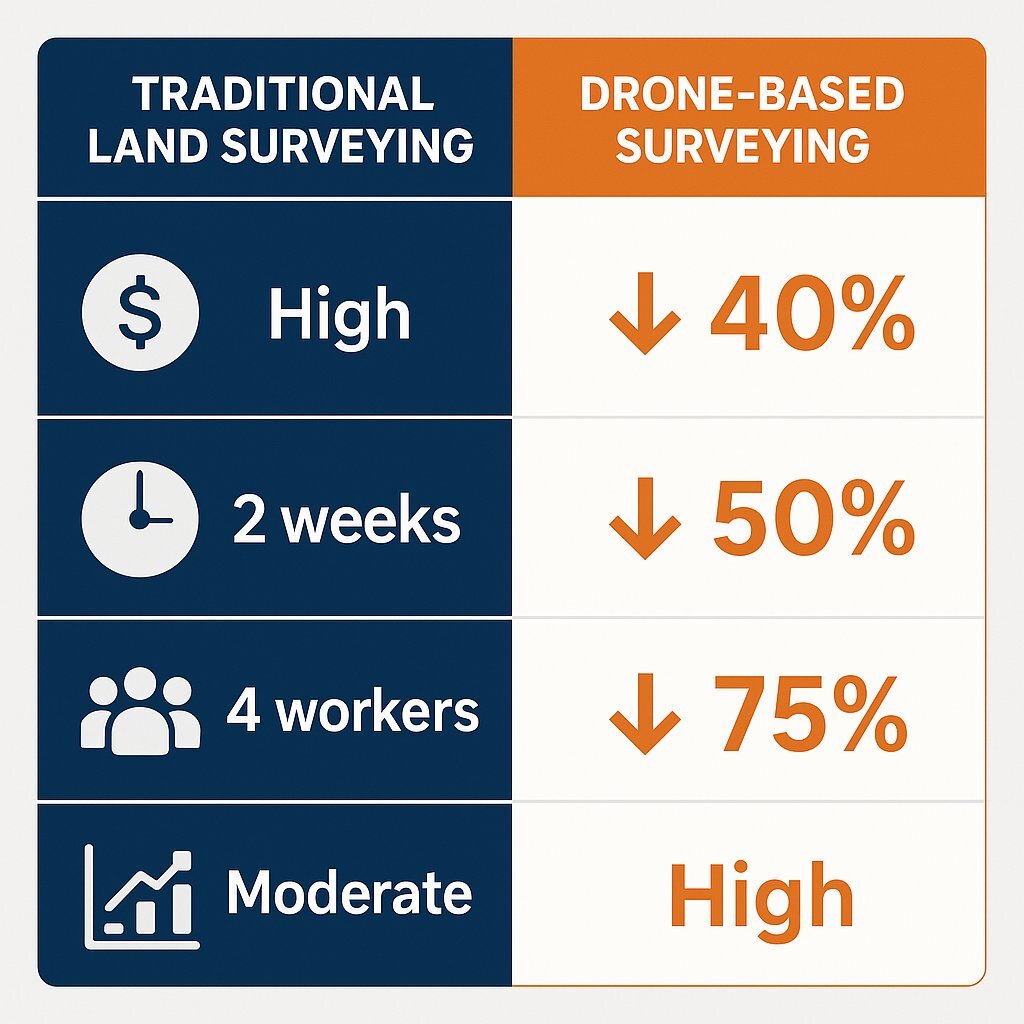

The Drone Dividend: Slashing Surveying Costs and Accelerating Timelines

The most immediate and easily quantifiable ROI comes from adopting drones for site surveying. The contrast with traditional methods is stark and provides a clear "quick win" for firms beginning their automation journey.

Traditional land surveys are labor-intensive, slow, and expensive. Costs can range from $1,500 for a single acre to over $25,000 for a 50-acre plot, with timelines stretching from days to weeks depending on the terrain's complexity. Drone-based surveying fundamentally changes this equation. As noted, drones can complete data capture up to 80% faster. This speed translates directly into cost savings. Financial analysis suggests that an initial investment of $5,000 to $10,000 in a professional-grade drone, software, and training can have a payback period of just six to twelve months, driven by labor cost savings that can range from $10,000 to $50,000 annually.

| Metric | Traditional Surveying | Drone Surveying | % Improvement |

|---|---|---|---|

| Estimated Cost | $2,500 – $4,400 | $500 – $1,500 | 60-77% Reduction |

| Time to Completion | 5 – 10 Days | 1 – 2 Days | 80% Reduction |

| Labor Requirement | 2-3 Person Crew | 1 Certified Pilot | 50-66% Reduction |

| Data Output | Boundary lines, key points | High-res 3D model, orthomosaic map | Enhanced Data Richness |

Table 1: Cost & Time Analysis: Traditional vs. Drone-Based Land Surveying (for a 5-acre commercial plot). Data synthesized from supporting articles.

The Robotics Payback: A Strategic Approach to Labor Amplification

The ROI for ground robots is more complex and strategic. While the high initial cost of acquisition is a primary challenge for many firms, viewing the investment through the lens of a single project is often misleading. The true financial payback is realized when robotics are deployed as a long-term, strategic solution to the industry's single greatest constraint: the skilled labor shortage.

For construction leaders exploring automation, it pays to understand how the Internet of Things (IoT) is also transforming construction, especially when robots, sensors, and drones all feed into a unified data strategy.

The most effective way to assess the ROI is not on a one-time basis but across a portfolio of projects. This multi-project, longer-term deployment model allows the initial capital expenditure to be amortized, while standardized processes unlock compounding efficiency gains. This approach transforms the robot from a project expense into a corporate asset that directly addresses labor capacity constraints. For GCs with a strong project pipeline, particularly in systematic and repetitive builds like data centers or infrastructure, this strategic investment becomes a powerful competitive differentiator.

| Metric | Traditional Mason Crew (2 masons, 1 laborer) | Augmented Crew (1 SAM Robot, 1 mason, 1 laborer) | Productivity Impact |

|---|---|---|---|

| Bricks Laid per Day | ~1,000 | ~2,500 | 150% Increase |

| Labor Cost per Day (est.) | $1,600 | $1,200 (excluding robot cost) | 25% Labor Savings |

| Cost per Brick (Labor Only) | ~$1.60 | ~$0.48 | 70% Reduction |

| Total Output | Standard | Amplified | Enables bidding on more projects |

Table 2: Productivity & Cost Analysis: Traditional vs. Robotic Bricklaying (per 8-hour day). Data synthesized from industry sources.

This analysis reveals a critical point: the true financial risk is not the cost of adoption, but the cost of inaction. In an environment where the skilled labor pool is shrinking, firms that cannot secure enough masons, welders, or equipment operators will be forced to turn down profitable work. Robotics provides a direct solution to this capacity problem. Therefore, any complete ROI calculation must include the "cost of the status quo"—the lost revenue from projects that a firm is unable to bid on due to labor unavailability. This reframes automation as a strategic necessity for future growth.

For a closer look at how estimating platforms can sharpen competitive bids, especially for complex construction work, see our deep dive on custom construction bidding software solutions and how they deliver ROI.

The Intangibles: De-risking Projects and Enhancing Safety

Beyond direct cost savings, automation delivers powerful benefits that are harder to quantify but have a massive impact on profitability and risk management.

- Enhanced Safety: Using robots for hazardous activities like demolition or welding improves site safety. Drone inspections of high-risk areas can reduce safety incidents by as much as 40% by detecting hazards before they cause an accident. A safer job site leads to lower insurance premiums, fewer costly project shutdowns due to accidents, and a stronger corporate reputation.

- Dispute Resolution: Drone footage provides a clear, objective, and time-stamped visual record of the entire project lifecycle. This "digital witness" is invaluable for resolving disputes with subcontractors, owners, or regulators, often preventing costly and time-consuming litigation by providing indisputable evidence of work completed.

- Quality Control & Rework Reduction: One of the largest hidden costs in construction is rework. By creating detailed 3D models, drones allow for early detection of structural issues or deviations from the plan. One case study demonstrated a 25% improvement in overall project ROI driven solely by this capability, as it prevented expensive rework that would have been discovered much later in the process.

The differing ROI models for drones and robots suggest a logical, phased adoption strategy. Drones represent a low-risk, high-return "quick win." A firm can adopt drone technology to achieve immediate cost savings in surveying and monitoring. This initial success builds internal competency with data capture, proves the value of digitization to stakeholders, and can even generate the cost savings needed to fund the larger, more strategic investment in ground robotics.

How Does All This Tech Work Together? The Critical Role of Software and Integration

The robots and drones capturing data on site are only the first part of the equation. The true value—the transformation from simply building faster to building smarter—is unlocked by the software ecosystem that processes, analyzes, and integrates this data into a single, coherent picture of the project.

From Data Capture to Actionable Insight: The Reality Capture Workflow

For a non-technical executive, the data lifecycle can be understood in three simple steps:

- Capture: Drones and ground robots act as mobile data capture platforms. Using an array of sensors—high-resolution cameras, LiDAR, thermal imagers—they collect immense amounts of raw data (images, laser point clouds) from the physical job site.

- Process: This raw data is then fed into specialized processing software (such as DJI Terra or Pix4Dbim). This software uses a technique called photogrammetry to stitch thousands of individual images and data points together into usable, intelligent formats: geometrically accurate 2D orthomosaic maps, detailed 3D models, and comprehensive "digital twins" of the site.

- Analyze: Finally, these processed models are hosted on a unified reality capture platform (like DroneDeploy or OpenSpace). Here, project managers, engineers, and executives can access the data, perform measurements, and analyze progress. Increasingly, these platforms use Artificial Intelligence (AI) to automate analysis, such as calculating stockpile volumes, tracking work-in-place against the schedule, or even detecting potential safety risks like missing guardrails.

Interested in the next step for data workflows? Our guide on artificial intelligence in construction shows how AI adoption now goes hand-in-hand with data-rich reality capture.

The BIM Connection: Aligning Digital Plans with On-Site Reality

The most transformative step in this workflow is the integration of field data with the project's Building Information Model (BIM). BIM is the "as-designed" digital blueprint—the master plan for the entire project. The data captured by drones and robots provides the "as-built" reality—a precise digital record of what actually exists on site at any given moment.

Today’s leaders know integration is key. For insight into bridging data between the field and the back office—without creating data silos—see our take on custom software for overcoming supply chain challenges, which shares useful strategies for the construction sector as well.

The power of this integration lies in overlaying the as-built model onto the as-designed BIM model. This direct comparison allows teams to instantly spot discrepancies between the plan and the on-site reality. Is a foundation wall poured a few inches off from the design? Are MEP rough-ins clashing with structural elements? This integration flags these issues in near real-time, allowing for corrections to be made before they become deeply embedded and exponentially more expensive to fix. Case studies have shown this capability can be revolutionary; Turner Construction, for example, saved 60% of its on-site inspection time by integrating drone data with BIM.

Curious how digital twins and data-rich reality capture platforms deliver a strategic advantage? Read more about unlocking enterprise knowledge with AI and document management—principles that apply as much to construction as to corporate operations.

Unlocking Full Value: Where Custom Software Creates Competitive Advantage

Off-the-shelf reality capture platforms are powerful and provide a fantastic starting point. However, every major construction firm operates with a unique and often complex technology stack, including legacy accounting systems, proprietary project management tools, and enterprise resource planning (ERP) software. While platforms like DroneDeploy offer standard integrations with major software like Procore and Autodesk, these off-the-shelf connectors often cannot bridge the gap to a firm's specific, customized systems. This "last mile" of integration is where true competitive advantage is forged.

This is the critical role of a strategic partner like Baytech Consulting. Baytech doesn't sell hardware; it builds the custom software "glue" that makes a company's entire technology ecosystem—from the drone in the sky to the ERP in the back office—work together seamlessly. True differentiation comes from a tailored software strategy that addresses a firm's unique workflows and challenges.

Consider these use cases for custom development:

- Unified Data Platform: Baytech can architect and build a central data warehouse that ingests information from drone platforms, robotic fleet managers, BIM files, your ERP, and scheduling software. This creates a single source of truth for all project data, breaking down silos and providing executives with a holistic, real-time dashboard of enterprise-wide operations.

- Bespoke Analytics & AI: While platforms have built-in AI, Baytech can develop custom machine learning models trained on your company's own historical project data. This proprietary model can provide far more accurate predictions for project-specific delays, cost overruns, and safety incidents than any generic algorithm, turning your historical data into a predictive asset.

- Advanced Automation Workflows: The cutting edge of construction automation involves integrating 4D BIM (the 3D model plus the time/schedule dimension) directly with robotic task planning. This allows for a level of automation where a schedule delay detected in the 4D BIM model could automatically re-task a robot on site to a different work area to maintain productivity. This sophisticated, context-aware automation requires custom software development to create the knowledge base and information flow between the BIM environment and the robotic operating system—precisely the kind of complex integration Baytech specializes in.

To explore why custom-built software often outpaces off-the-shelf tools in construction and beyond, check out our comparison of low-code versus custom development for B2B leaders.

Adopting this technology forces a fundamental shift from project-based thinking to platform-based thinking. A firm is no longer just building individual buildings; it is building a massive, proprietary dataset on how it builds. This data, when managed by a custom-built central platform, becomes a strategic corporate asset that can be used to benchmark performance, train predictive AI, and drive enterprise-wide improvements that transcend any single project. Ultimately, the product being created by this entire tech ecosystem is not just a 3D model or a faster-laid wall; it is certainty. In an industry defined by uncertainty, this technology provides certainty about site conditions, progress, quality, and cost, giving leadership an unprecedented level of confidence and control.

How Do We Get Started? A Practical Roadmap for Adoption

Embarking on a technological transformation can seem daunting. A strategic, phased approach is the key to managing risk, building momentum, and ensuring long-term success.

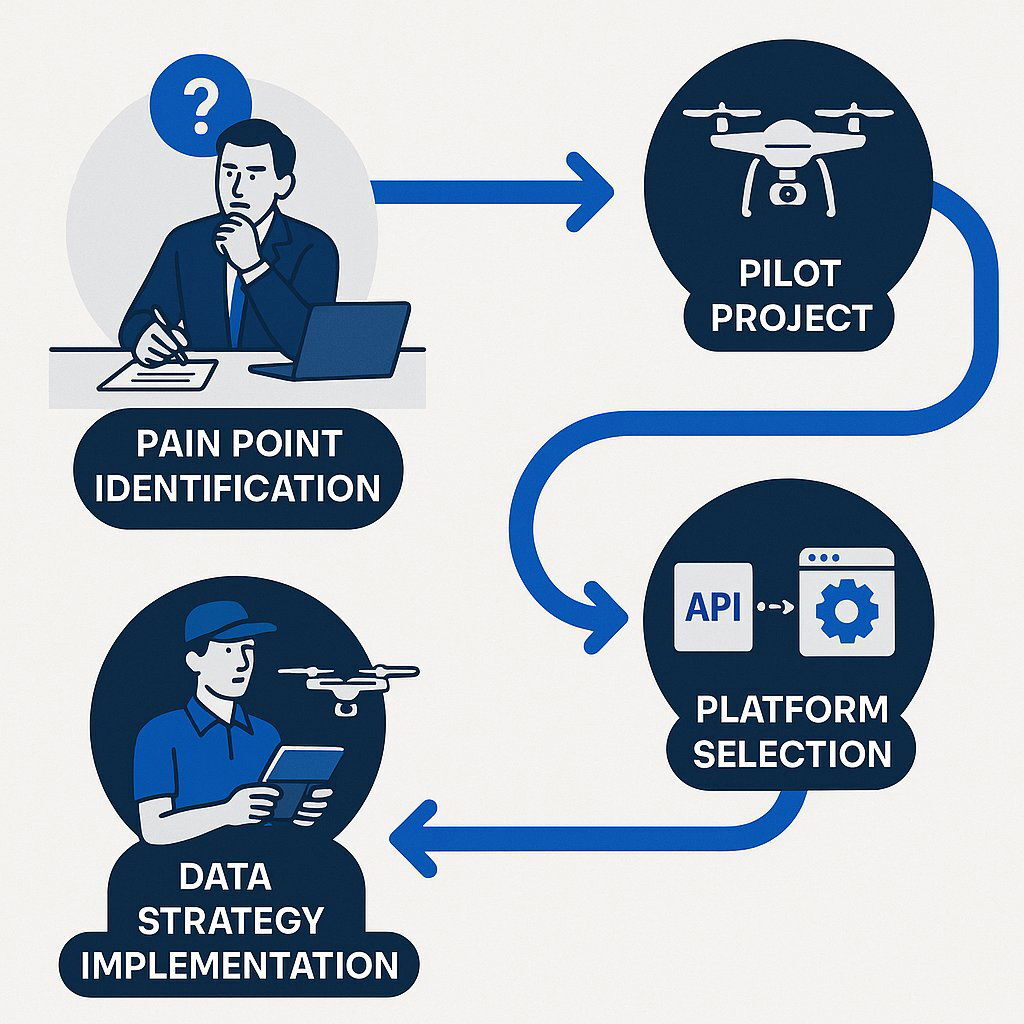

Step 1: Identify the Greatest Pains and Launch a Pilot Project

Resist the urge for a "boil the ocean" approach that tries to automate everything at once. The most successful adoption strategies start small, prove value in a controlled environment, and use that success to build broader buy-in.

Begin by identifying a single, significant, and measurable pain point in your operations. Are surveying delays and costs a constant headache on every project? A drone pilot program is the logical starting point. Are you consistently turning down profitable masonry contracts due to a lack of skilled labor? A pilot with a single bricklaying robot on a suitable project would be a focused and strategic test. Using the clear, quick ROI of drones is often an effective first step to demonstrate the power of site digitization and build the business case for more complex and capital-intensive robotic systems.

For more on making the case to leadership and phasing tech adoption, discover our detailed roadmap for integrating AI in B2B operations—much of its stepwise approach applies directly to construction's leap into automation.

Step 2: Choose Your Platforms and Partners Wisely

When evaluating hardware and software, it is crucial to think in terms of an ecosystem, not just point solutions. The most important question to ask any vendor is not just "What can your product do?" but "How easily can I get data out of your system and integrate it with my other critical tools?".

Prioritize platforms with open Application Programming Interfaces (APIs) and a strong track record of successful integrations. This approach future-proofs your investment, ensuring that the technology you choose today can grow with your needs and will not become an isolated data silo tomorrow.

Interested in best practices for integrating new software and driving adoption? Our article on overcoming team resistance to digital transformation in manufacturing highlights lessons that can ensure executive buy-in and long-term success on the job site.

Step 3: Architect Your Data Strategy from Day One

The most common mistake firms make is treating data strategy as an afterthought. The long-term, strategic value of this transformation is in the data. Therefore, your data strategy must be developed in parallel with your hardware pilot.

This is the ideal moment to engage a strategic software partner like Baytech Consulting. By bringing in an expert early, you can architect a scalable data infrastructure from the beginning. Baytech can help ensure that the data collected during your initial pilot projects is clean, structured, and captured in a way that makes it ready for integration into a larger enterprise platform. This proactive approach avoids the creation of disconnected data pools that will be technically difficult and costly to unify later, setting the foundation for a truly data-driven construction enterprise.

Conclusion: Building the Future, Today

The construction industry stands at a crossroads, facing existential challenges related to labor, margins, and safety. Robotic automation and drones are no longer speculative technologies; they are proven, available solutions that offer a clear path forward. The return on investment is compelling, moving beyond simple cost savings to encompass strategic advantages in productivity, quality, and risk mitigation.

However, the hardware is only the vehicle. The engine of this transformation is a cohesive software and data strategy that unifies these powerful tools into an intelligent, interconnected system. The future construction site will be a dynamic environment where aerial data from drones informs the real-time execution of ground-level robots, with every action monitored and managed through a unified digital twin that aligns perfectly with the project's master plan. This is the future of building—a future that is safer, more efficient, and more certain.

The hardware is only the first step. To build a true, sustainable competitive advantage, you need a data strategy that unifies your technology, your projects, and your teams.

Contact Baytech Consulting today to schedule a consultation on how a custom software solution can transform your construction operations.

Supporting Articles

- An Overview of Drone Applications in the Construction Industry

- https://builtworlds.com/news/case-construction-robotics/

- https://www.mckinsey.com/capabilities/mckinsey-digital/our-insights/the-top-trends-in-tech

About Baytech

At Baytech Consulting, we specialize in guiding businesses through this process, helping you build scalable, efficient, and high-performing software that evolves with your needs. Our MVP first approach helps our clients minimize upfront costs and maximize ROI. Ready to take the next step in your software development journey? Contact us today to learn how we can help you achieve your goals with a phased development approach.

About the Author

Bryan Reynolds is an accomplished technology executive with more than 25 years of experience leading innovation in the software industry. As the CEO and founder of Baytech Consulting, he has built a reputation for delivering custom software solutions that help businesses streamline operations, enhance customer experiences, and drive growth.

Bryan’s expertise spans custom software development, cloud infrastructure, artificial intelligence, and strategic business consulting, making him a trusted advisor and thought leader across a wide range of industries.